A high resistivity sintered r-fe-b permanent magnet and preparation method thereof

A high-resistivity, permanent magnet technology, used in the manufacture of inductors/transformers/magnets, magnetic objects, circuits, etc., can solve the problems such as the inability to realize the controllable preparation of the coating thickness, the decrease of the magnet density, and the complicated operation, and achieve the The effect of exchange coupling between grains, reducing the loss of magnetic properties, and cheap and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

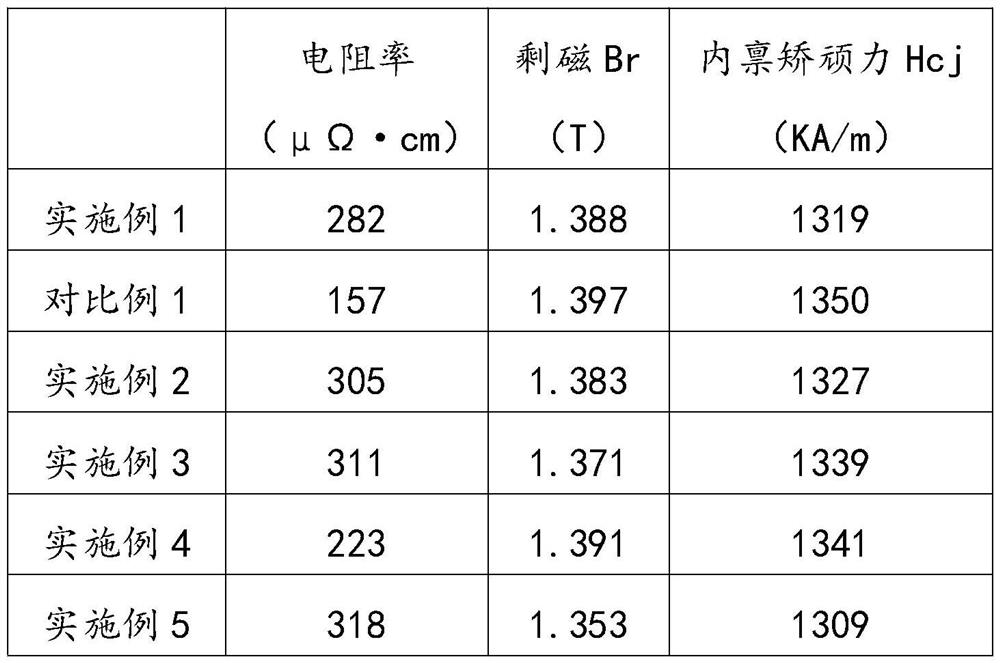

Embodiment 1

[0034] A preparation method of a high resistivity sintered Nd-Fe-B permanent magnet, the steps are as follows:

[0035] (1) The Nd-Fe-B alloy is melted in an argon atmosphere at 1400°C, and cast on the surface of a rotating quenching roll to form a Nd-Fe-B alloy quick-setting sheet; among them, in the Nd-Fe-B alloy , Nd accounts for 30wt%, B accounts for 1.0wt%, Ti accounts for 0.7wt%, Al accounts for 0.7wt%, Ga accounts for 1.6wt%, and the rest is Fe;

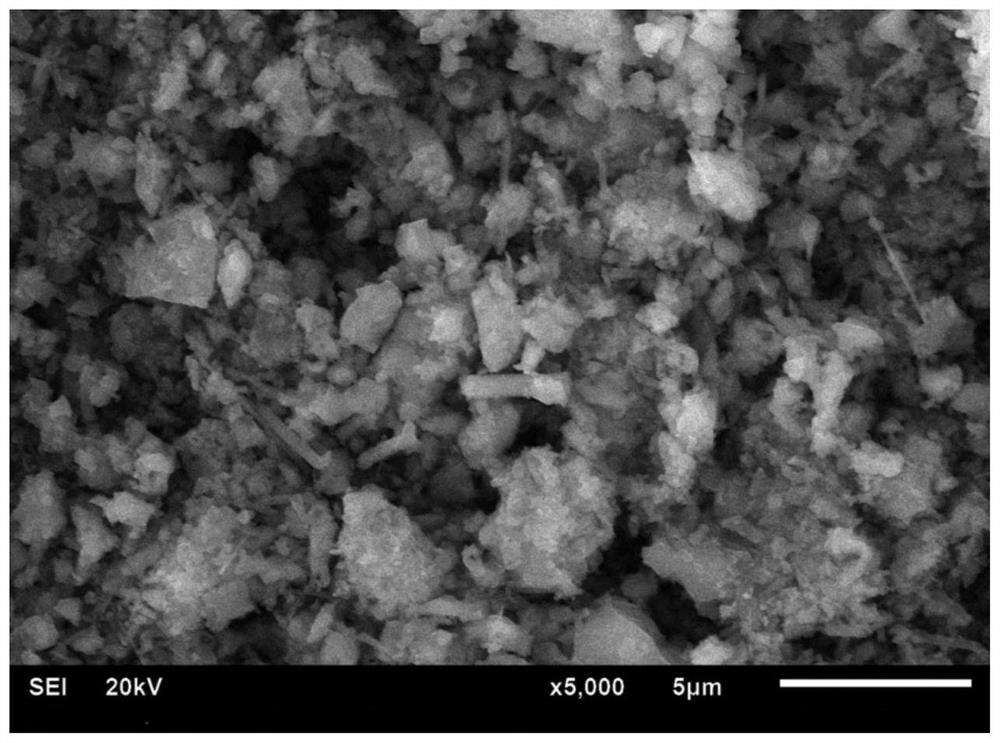

[0036] (2) take 100kg of Nd-Fe-B alloy quick-setting flakes in step (1) and grind them through hydrogenation-ball milling-air jet mill to obtain magnetic powder with a particle size of 1-10 μm and an average particle size of 2.7 μm;

[0037] (3) adding carbon nitride precursor 0.2kg dicyandiamide into 0.5kg organic lubricant fatty acid ester, and continuously mechanically stirring for 4h to uniformly disperse, to obtain carbon nitride precursor dispersant 0.7kg;

[0038] (4) Continuously spraying the carbon nitride precursor ...

Embodiment 2

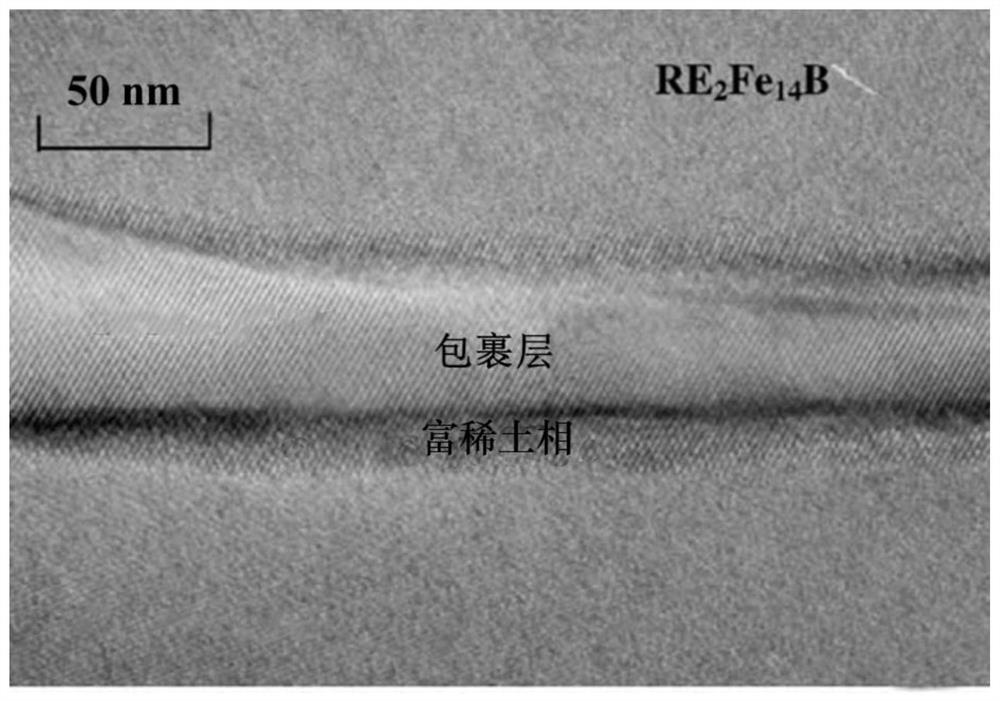

[0050] The preparation method of this embodiment is the same as that of embodiment 1, and the difference lies in that: the amount of dicyandiamide in step (3) is 0.25kg; the same detection method of embodiment 1 is used to measure the in-situ generation of magnetic powder crystal grains Carbon nitride wrapping layer with a thickness of 169nm.

Embodiment 3

[0052] The preparation method of this embodiment is the same as that of embodiment 1, and the difference lies in: the amount of dicyandiamide in step (3) is 0.325kg; the same detection method of embodiment 1 is adopted, it is measured that the in-situ generation of magnetic powder crystal grains is generated Carbon nitride wrapping layer with a thickness of 246nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com