Flame-retardant building thermal insulation material

A nano-silica, modified technology, used in fibrous fillers, inorganic pigment treatment, household appliances, etc., can solve the problems of releasing a large amount of toxic fumes, melting deformation, flammability, etc., to inhibit the transmission of substances and energy, The effect of enhanced interfacial interaction and reduced heat release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

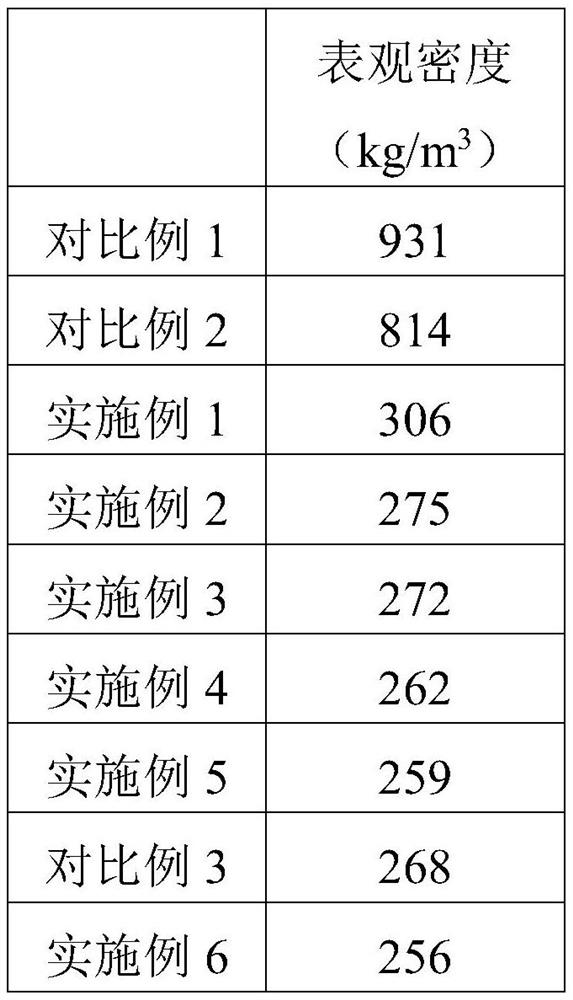

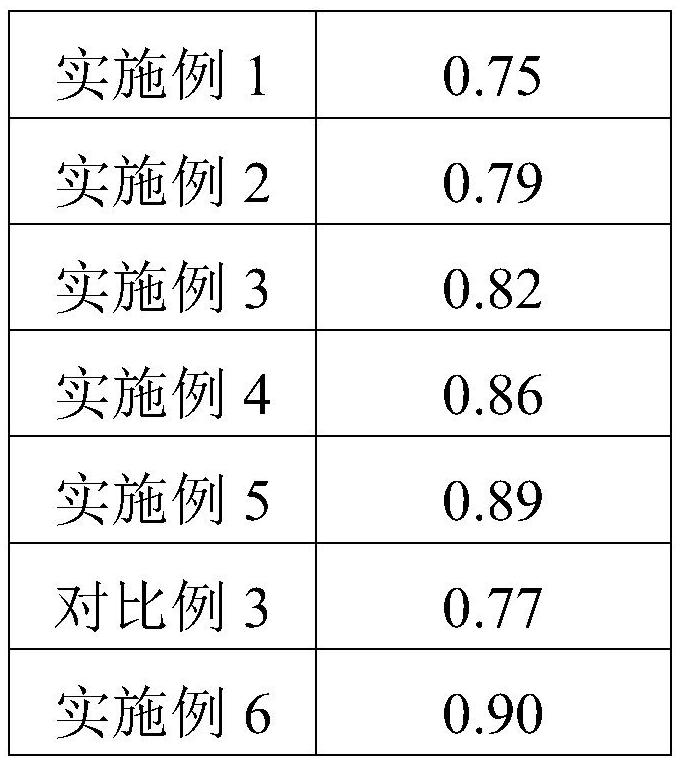

Embodiment 1

[0057] The flame-retardant building insulation material is composed of the following components: Portland cement 130kg / m 3 , fly ash 45kg / m 3 , mass fraction 27.5% hydrogen peroxide solution 9.1kg / m 3 , foam-stabilizing and coagulation-promoting emulsion 4.5kg / m 3 , tap water 100kg / m 3 , tackifier 1.1kg / m 3 , polypropylene fiber 0.54kg / m 3 , styrene-butadiene rubber / rubber powder composite material 12.8kg / m 3 .

[0058] The weight ratio of the foam-stabilizing and coagulation-accelerating emulsion is: stearic acid: potassium hydroxide: sodium carbonate: ammonia water with a mass fraction of 40%: sodium fluoride: water = 9: 1.2: 0.6: 4.6: 0.05: 142.

[0059] The preparation method of the foam-stabilizing and coagulation-accelerating emulsion is as follows: first add water with a ratio of 1 / 2 of the foam-stabilizing and coagulation-accelerating emulsion into the container, and heat the water to reach 60°C; dissolve sodium carbonate, potassium hydroxide and sodium fluoride ...

Embodiment 2

[0066] The flame-retardant building insulation material is composed of the following components: Portland cement 130kg / m 3 , fly ash 45kg / m 3 , mass fraction 27.5% hydrogen peroxide solution 9.1kg / m 3 , foam-stabilizing and coagulation-promoting emulsion 4.5kg / m 3 , tap water 100kg / m 3 , tackifier 1.1kg / m 3 , polypropylene fiber 0.54kg / m 3 , styrene-butadiene rubber / rubber powder composite material 12.8kg / m 3 .

[0067] The weight ratio of the foam-stabilizing and coagulation-accelerating emulsion is: stearic acid: potassium hydroxide: sodium carbonate: ammonia water with a mass fraction of 40%: sodium fluoride: water = 9: 1.2: 0.6: 4.6: 0.05: 142.

[0068] The preparation method of the foam-stabilizing and coagulation-accelerating emulsion is as follows: first add water with a ratio of 1 / 2 of the foam-stabilizing and coagulation-accelerating emulsion into the container, and heat the water to reach 60°C; dissolve sodium carbonate, potassium hydroxide and sodium fluoride ...

Embodiment 3

[0076] The flame-retardant building insulation material is composed of the following components: Portland cement 130kg / m 3 , fly ash 45kg / m 3 , mass fraction 27.5% hydrogen peroxide solution 9.1kg / m 3 , foam-stabilizing and coagulation-promoting emulsion 4.5kg / m 3 , tap water 100kg / m 3 , tackifier 1.1kg / m 3 , polypropylene fiber 0.54kg / m 3 , styrene-butadiene rubber / rubber powder composite material 12.8kg / m 3 .

[0077] The weight ratio of the foam-stabilizing and coagulation-accelerating emulsion is: stearic acid: potassium hydroxide: sodium carbonate: ammonia water with a mass fraction of 40%: sodium fluoride: water = 9: 1.2: 0.6: 4.6: 0.05: 142.

[0078] The preparation method of the foam-stabilizing and coagulation-accelerating emulsion is as follows: first add water with a ratio of 1 / 2 of the foam-stabilizing and coagulation-accelerating emulsion into the container, and heat the water to reach 60°C; dissolve sodium carbonate, potassium hydroxide and sodium fluoride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com