Cosmetic composition, and cosmetic and preparation method thereof

A cosmetic composition and a cosmetic technology are applied in the fields of cosmetic compositions, cosmetics and their preparation, and can solve the problems of poor skin absorption effect, high price, weak other effects, etc. The effect of absorptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

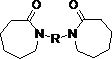

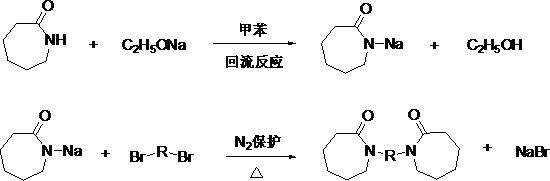

[0034] Example 1-5 Preparation of Azone

[0035] The synthetic route is as follows:

[0036]

[0037] S1. Add 2mol of caprolactam and 2mol of sodium ethoxide into 200mL of toluene, stir to dissolve, and heat to reflux for 2h to generate sodium caprolactam;

[0038] S2. Add 2 mol of caprolactam sodium salt under the protection of nitrogen to 1 mol of dibromoalkane dichloromethane solution, heat to boiling, and react for 4 hours to generate new laurin derivatives;

[0039] The dibromoalkane has the following general formula: Br-R-Br, R=C10-14 linear alkyl.

[0040]

[0041] NMR results of compound 1: 1 H NMR(300MHz, CDCl 3 )δ3.2-3.22 (m, 8H), 2.18 (t, 4H), 1.54-1.56 (m, 14H), 1.29-1.31 (m, 14H).

[0042] NMR results of compound 2: 1 H NMR(300MHz, CDCl 3 )δδ3.2-3.22 (m, 8H), 2.18 (t, 4H), 1.53-1.57 (m, 16H), 1.29-1.32 (m, 14H).

[0043] NMR results of compound 3: 1 H NMR(300MHz, CDCl 3 )δδ3.2-3.22 (m, 8H), 2.18 (t, 4H), 1.52-1.56 (m, 18H), 1.29-1.32 (m, 14H).

[0044] NMR results of compound ...

Embodiment 6

[0047] Raw material composition (parts by weight): 3 parts of Dendrobium candidum extract, 2 parts of Paeonia suffruticosa extract, 1 part of Rhodiola rosea extract, 1 part of the novel azone derivative prepared in Example 5, 55 parts of xanthan gum, 25 parts of 1,3-propanediol, 23 parts of 1,2-propanediol, 42 parts of phytosphingosine, 1 part of triethanolamine, 1 part of nicotinamide, 1 part of carbomer, 1 part of acid-hydrolyzed casein, 0.01 part of hyaluronic acid Parts, 0.1 part of kojic acid, 1 part of sodium diacetate, 30 parts of butanediol, 1 part of p-methoxycinnamate isoamyl ester, and 400 parts of deionized water.

[0048] The preparation method of Dendrobium officinale extract is as follows: Wash Dendrobium officinale, dried and pulverize to below 100 mesh to obtain a fine powder; add 10g of fine powder to 50mL enzyme extract and stir for 1 hour for enzymatic hydrolysis, and apply 100W ultrasound during the extraction process After the extraction, the enzyme is inact...

Embodiment 7

[0056] Composition of raw materials (parts by weight): 10 parts of Dendrobium candidum extract, 5 parts of Paeonia suffruticosa extract, 4 parts of Rhodiola rosea extract, 2 parts of novel azone derivatives prepared in Example 5, 70 parts of xanthan gum, 1,3-propanediol 50 parts, 1,2-propanediol 42 parts, phytosphingosine 65 parts, triethanolamine 3 parts, nicotinamide 4 parts, carbomer 5 parts, acid hydrolyzed casein 2 parts, hyaluronic acid 0.1 Parts, 1 part of aspergillic acid, 4 parts of calcium propionate, 50 parts of octocrelin, 3 parts of sunscreen, 1000 parts of deionized water.

[0057] The preparation method of Dendrobium officinale extract is as follows: Wash Dendrobium officinale, smash it to below 100 meshes after sun-drying, to obtain fine powder; add 10g of fine powder to 100mL enzyme extract and stir for enzymatic hydrolysis for 3h, and apply 200W ultrasound during the extraction process After the extraction, the enzyme is inactivated. The enzyme inactivation cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com