Spherical titanium-aluminum alloy powder and preparation method and application thereof

A titanium-aluminum alloy and spherical technology is applied in the field of spherical titanium-aluminum alloy powder and its preparation. High density, solve the effect of bad sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

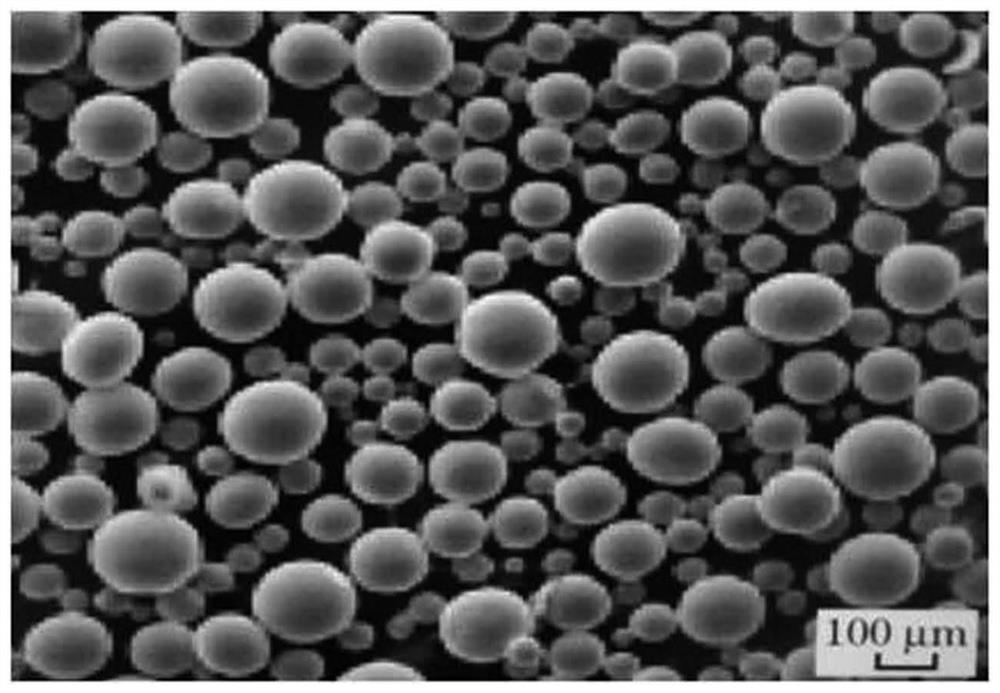

[0028] In an exemplary embodiment of the present invention, the preparation method of the spherical titanium-aluminum alloy powder may include: titanium-aluminum alloy bar stock → soaking treatment → turning processing → installing raw material rods → vacuuming → filling inert gas → Arc ignition→centrifugal atomization→cooling→sieving and packaging.

[0029] In this embodiment, the titanium-aluminum alloy bar (also referred to as a raw material bar) can be selected: a bar of a vacuum consumable electrode melting ingot or a forged alloy bar, or a titanium alloy produced by powder metallurgy. Aluminum alloy bars. Titanium-aluminum alloy rods may include chemical compositions in terms of atomic percent (at.%):

[0030] 40-69% Ti, for example, 41%, 45%, 50%, 55%, 60%, 65, 68%, etc.

[0031] 30-49% Al, such as 31%, 35%, 40%, 45%, 48%, etc.

[0032] The rest: one or more of niobium, vanadium, chromium, tungsten, yttrium and other elements, as well as unavoidable impurity elements...

example 1

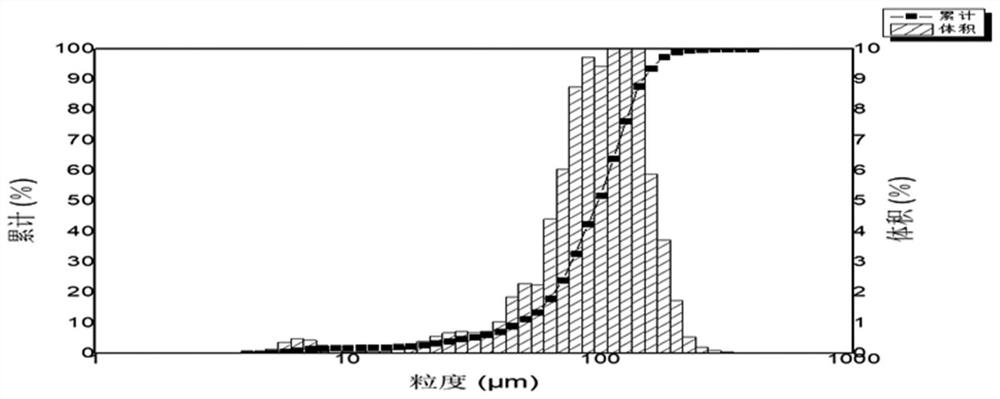

[0050] Ti-48Al-2Cr-2Nb series titanium-aluminum alloy rods are used as raw materials, and the atomic percentage (at.%) of the chemical composition of the titanium-aluminum alloy rods is Al: 47-49%, Cr: 1.5-2.5%, Nb: 1.5-2.5 %, the balance is Ti and impurity elements, the relative density is greater than 99%, and the mass percent wt% of its chemical composition is shown in Table 1.

[0051] Process the titanium-aluminum alloy rod into a titanium-aluminum alloy raw material rod with a diameter of ф50×450mm, and remove impurities on the surface of the raw material rod.

[0052] Put the raw material rod after removing impurities into the arc centrifugal atomization device (ie arc melting rotary atomization device), the vacuum degree is ≤3×10 -3 Pa, and then the inert gas argon is introduced into the device. Under the condition of ensuring that the oxygen content in the atomization chamber is ≤4ppm, the arc melting centrifugal atomization device is turned on under the protection o...

example 2

[0063] Ti-45Al-8Nb-W-Y series titanium aluminum alloy rod is used as raw material, the main chemical composition of Ti-45Al-8Nb-W-Y series (atomic percentage at.%) Al: 45-46%, Nb: 5-10%, W: 0.2-1%, Y: 0.01-0.1%, the balance is Ti and impurity elements, and its relative density is greater than 99%. Process the titanium-aluminum alloy rod into a titanium-aluminum alloy raw material rod with a diameter of Ф80×350 mm, and remove impurities on the surface of the raw material rod.

[0064] Put the titanium-aluminum alloy raw material rod into the arc centrifugal atomization device, and the vacuum degree is ≤3×10 -3 Pa, and then a mixed inert gas is introduced into the device.

[0065] The volume ratio of argon gas with a purity of 99.999% in the mixed inert gas fed in is 70%, the volume ratio of helium gas with a purity of 99.999% is 30%, the total flow rate of the mixed inert gas is 670L / min, and its pressure is 0.6±0.05 MPa.

[0066] To ensure that the oxygen content in the ato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com