Method for purifying xylose hydrolysate through desalination by three-zone simulated moving bed

A technology for simulating moving bed and xylose hydrolyzate, applied in the field of functional sugar production and separation, can solve the problems of inorganic salt ion contamination of functional partitions, increase of control sites and matching valves, complicated operation steps and system, etc., and achieve simplified control. System and device operation steps, the effect of reducing the amount and number of columns, and reducing the amount of process wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of three-zone simulated moving bed chromatographic desalination to purify the method of xylose hydrolyzate is as follows:

[0033] (1) Pretreatment of xylose hydrolyzate: corncobs were hydrolyzed with 0.5% (m / m) dilute hydrochloric acid for 1.5h at a temperature of 105°C and a working pressure of 0.15Mpa, and the obtained xylose hydrolyzate was neutralized to pH with calcium carbonate 5. Remove solid impurities and insolubles by precision filtration; the xylose filtrate is controlled at 60°C by a vacuum rotator, single-effect evaporator, or three-effect evaporator, etc., and evaporated and concentrated to obtain a refractive concentration of 55%, a conductivity of Sugar solution of 220000μS / m is used as raw material;

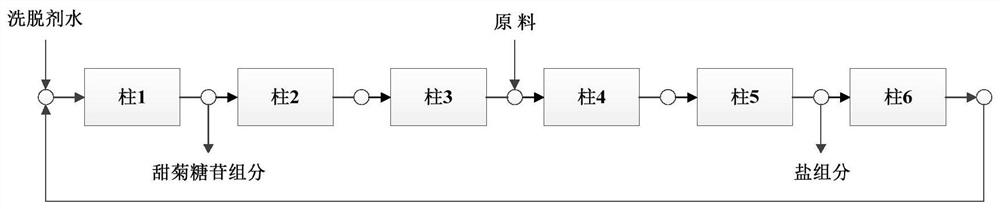

[0034] (2) Assembly and process design of the three-zone simulated moving bed chromatography device: between the eluent inlet and the extract outlet is zone I (extraction zone), between the extract solution outlet and raw material inlet is zone II ...

Embodiment 2

[0040] A kind of three-zone simulated moving bed chromatographic desalination to purify the method of xylose hydrolyzate is as follows:

[0041] (1) Pretreatment of xylose hydrolyzate: corncobs were hydrolyzed with 1.2% (m / m) dilute sulfuric acid for 1.5h at a temperature of 115°C and a working pressure of 0.1Mpa, and the obtained xylose hydrolyzate was neutralized with sodium hydroxide to pH 4.5, remove solid impurities and insolubles by precision filtration; xylose filtrate is controlled at 65°C by vacuum rotary instrument, single-effect evaporator, or three-effect evaporator, etc., evaporated and concentrated to obtain a refractive concentration of 60%, conductivity Sugar solution with a rate of 240000μS / m is used as raw material;

[0042] (2) Assembly and process design of the three-zone simulated moving bed chromatography device: between the eluent inlet and the extract outlet is zone I (extraction zone), between the extract solution outlet and raw material inlet is zone ...

Embodiment 3

[0048] A kind of three-zone simulated moving bed chromatographic desalination to purify the method of xylose hydrolyzate is as follows:

[0049] (1) Pretreatment of xylose hydrolyzate: corncobs were hydrolyzed with 1.5% (m / m) hydrochloric acid for 1.5h at a temperature of 120°C and a working pressure of 0.15Mpa, and the obtained xylose hydrolyzate was neutralized to pH 5.5 with sodium carbonate , to remove solid impurities and insolubles through precision filtration; the xylose filtrate is passed through a vacuum rotator, or a single-effect evaporator, or a three-effect evaporator to control the temperature at 70 ° C, evaporate and concentrate to obtain a refractive concentration of 50%, and a conductivity of 190000μS / m sugar liquid, as raw material;

[0050] (2) Assembly and process design of the three-zone simulated moving bed chromatography device: between the eluent inlet and the extract outlet is zone I (extraction zone), between the extract solution outlet and raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com