Petal-shaped ferroferric oxide-based composite wave-absorbing agent, preparation method thereof and wave-absorbing material

A ferroferric oxide and petal-shaped technology, which is applied in the petal-shaped ferric oxide-based composite absorber and its preparation field, can solve the problems that the composition affects the high-temperature electromagnetic wave absorption performance, the electromagnetic wave absorption frequency band is narrow, and the impedance matching is difficult to meet. , to achieve the effects of strong microwave absorption performance, effective electromagnetic wave absorption frequency bandwidth, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a preparation method of a petal-shaped ferric oxide-based composite wave absorbing agent, comprising the following steps:

[0033] (1) Preparation of rGO / iron alkoxide by reflux and co-precipitation

[0034] First measure 360mL ethylene glycol and place it in a beaker, then place the weighed 2.4g FeCl 3 ·6H 2 0, 5.4g urea, the graphene oxide of 14.4g tetrabutylammonium bromide and 0.1288g join in the above-mentioned beaker, after magnetic stirring and ultrasonic dispersion, the mixed solution is transferred to the 500mL three-necked flask placed in the oil bath, After raising the temperature of the oil bath to 200° C. while magnetically stirring, condense and reflux for 35 minutes. After reflux, the rGO / iron alkoxide gray-green powder was obtained after being collected by centrifugation and washed several times with ethanol, and then dried in a vacuum oven at 60°C for 8 hours.

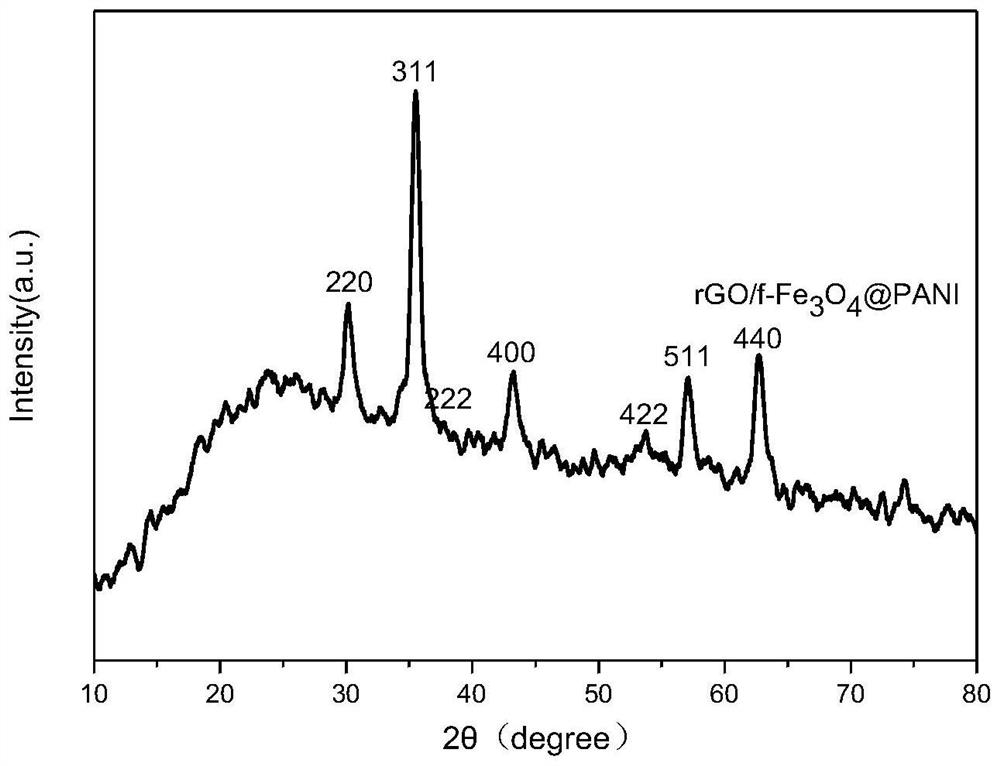

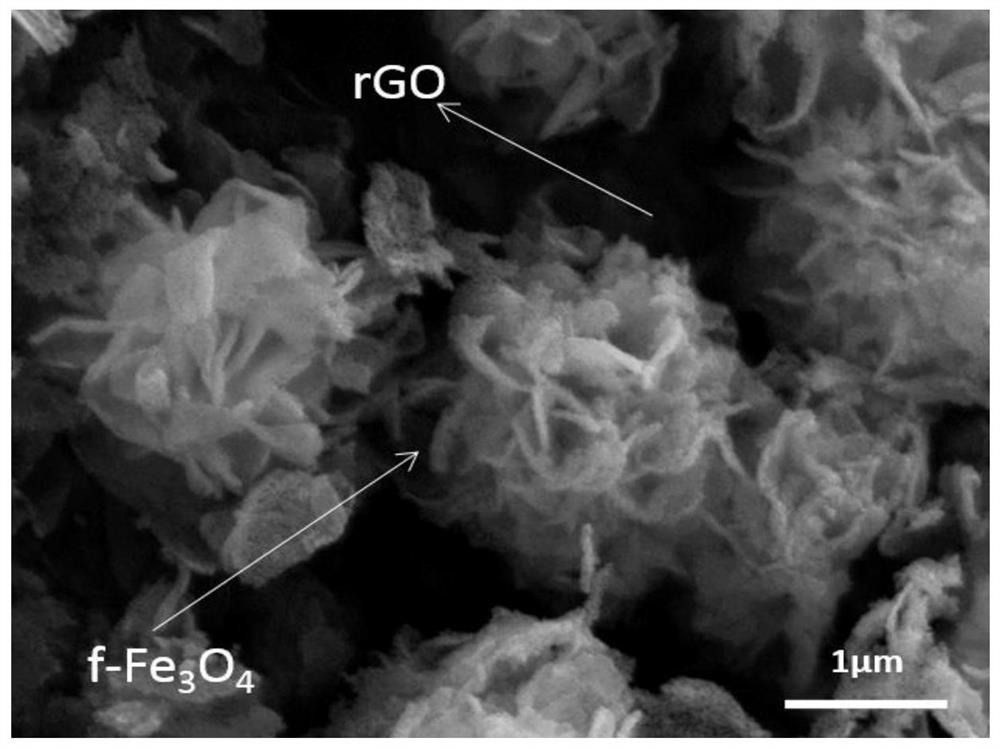

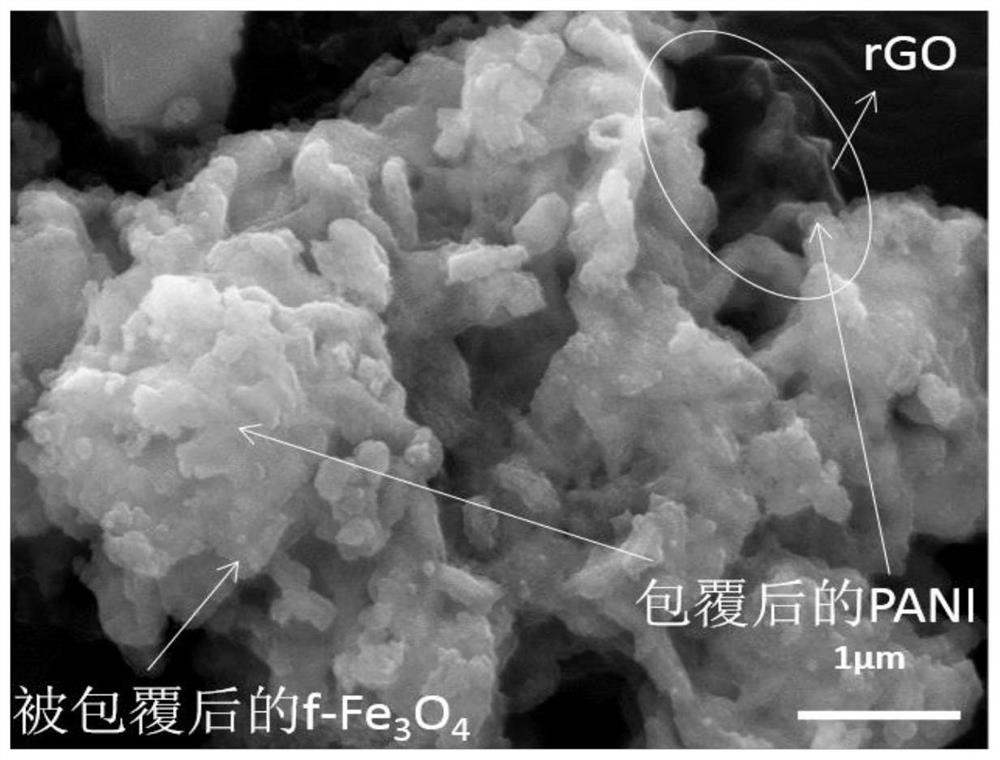

[0035] (2) Preparation of rGO / petal-like Fe by calcination 3 o ...

Embodiment 2

[0042] This embodiment provides a preparation method of a petal-shaped ferric oxide-based composite wave absorbing agent, comprising the following steps:

[0043] (1) Preparation of rGO / iron alkoxide by reflux and co-precipitation

[0044] First measure 360mL ethylene glycol and place it in a beaker, then place the weighed 2.4g FeCl 3 ·6H 2 0, 5.4g urea, the graphene oxide of 14.4g tetrabutylammonium bromide and 0.0644g join in the above-mentioned beaker, after magnetic stirring and ultrasonic dispersion, mixed solution is transferred to the 500mL there-necked flask that is placed in the oil bath, After raising the temperature of the oil bath to 220° C. while magnetically stirring, condense and reflux for 30 minutes. After reflux, it was collected by centrifugation and washed several times with ethanol, and then dried in a vacuum oven at 60°C for 12 hours to obtain rGO / iron alkoxide gray-green powder.

[0045] (2) Preparation of rGO / petal-like Fe by calcination 3 o 4 -2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com