Tear-resistant spunlace non-woven fabric and preparation method thereof

A spunlace non-woven and noil technology, which is applied in non-woven fabrics, textiles and papermaking, biochemical fiber processing, etc., can solve the problems of cracking, poor strength and durability, and achieve high comfort, soft touch, and inhibition. effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The main components of the spunlace non-woven fabric include: natural skeleton fibers, synthetic fibers, and synthetic auxiliaries. The natural skeleton fiber is mainly selected from the following fibers: ramie noil fiber, sisal noil fiber, kapok fiber; the synthetic fiber is mainly selected from poly-1,3-propylene terephthalate, polypropylene; The synthetic auxiliary agent is selected from calcium alginate and alumina.

[0017] The ramie noil fiber is the noil produced by the ramie fiber in the long hemp spinning and carding process, and specifically includes the noil combed by the ramie spinning new technology comber and the old technology two circular carding machines in the weaving process, ramie noil. The length of the noil fiber is about 25-35mm, and the fineness is 3.8 dtex; the sisal noil fiber is the noil produced by the sisal fiber in the process of weaving and carding, and the length of the sisal noil fiber is about 18-22mm, and the fineness is about 18-22mm....

Embodiment 2

[0024] Preparation of softening finishing agent: The softening finishing agent includes 85% adhesive, 1.5% hydrophilic silicone softener%, and 3.5% penetrating agent by mass fraction, and the adhesive is glycidyl methacrylate, acrylic acid- The copolymer emulsion composed of 2-ethyl ethyl ester, methyl methacrylate and acrylic acid, the crosslinking agent used in the copolymerization is epoxy acrylate.

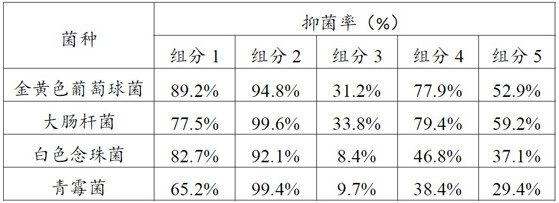

[0025] Preparation of novel antibacterial finishing solution: add 0.2 molar amount of 3-(3'-propyl acrylate)-5,5-dimethylhydantoin and equimolar amount of trimethylamine to 100 mL of tetrahydrofuran, and stir the mixture 10 minutes until the solute dissolves to obtain a first mixed solution; after cooling to 4° C., add 0.1 molar acryloyl chloride dropwise, and after stirring, place the mixed solution at room temperature for one day to obtain a second mixed solution. The solution was dissolved in acetone solution at a concentration of 6.58% to obtain the novel antibacterial fin...

Embodiment 3

[0027] Step 1. Raw material preparation

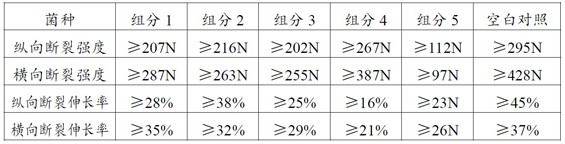

[0028] Component 1, Component 2, Component 3, Component 4, and Component 5 are weighed with reference to the raw material formulation of the non-woven fabric described in Example 1.

[0029] Step 2. Preparation of fiber layer

[0030] Soak the prepared fiber raw materials (including natural skeleton fibers and / or synthetic fibers) in the softening and finishing agent described in Example 2, and place them at room temperature for 24 hours. The fiber block is mechanically beaten, torn and loosened into short fiber bundles, and the opened fibers are fed into the fiber bin, after the fibers with different properties are fully mixed, the mixed fibers are made into a uniform fiber web and enter the carding process.

[0031] Step 3: The carding process adopts a two-comb and one-laying production line. The fiber web output by one carding machine is first fed to the cross-lapper for web-laying, and then the tractor draws the laid-up fiber web,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| fineness modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com