Fluosilicic acid for lead electrolysis and preparation method thereof

A technology of fluorosilicic acid and lead electrolysis, which is applied in the preparation of fluorosilicic acid for lead electrolysis and the field of fluorosilicic acid for lead electrolysis, which can solve the problem of decreasing the content of fluorosilicic acid, increase the preparation operation process of lead electrolyte, and increase the amount of lead electrolyte production cost etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

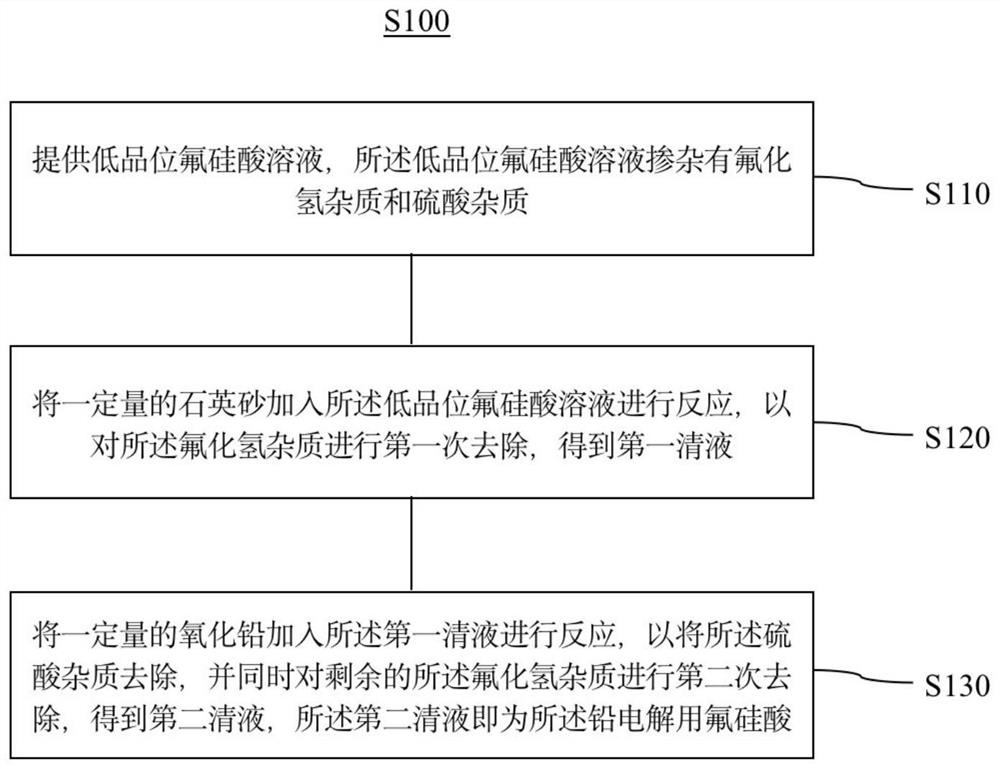

[0038] like figure 1 As shown, one aspect of the present invention provides a preparation method S100 of fluosilicic acid for lead electrolysis, which specifically includes the following steps S110-S130:

[0039] S110, providing a low-grade fluosilicic acid solution, the low-grade fluosilicic acid solution doped with hydrogen fluoride impurities and sulfuric acid impurities.

[0040] It should be noted that the low-grade fluosilicic acid solution provided in this example is a by-product when producing anhydrous hydrogen fluoride, and the main components it contains are: H 2 SiF 6 , HF, H 2 SO 4 , for the lead electrolysis industry, the doped hydrogen fluoride impurities and sulfuric acid impurities have certain adverse effects, and further removal is required to obtain higher-purity fluosilicic acid, so that the low-grade fluosilicic acid can be effectively used, which requires Analyze the content of each component, and then remove the corresponding impurities according to...

Embodiment 1

[0057] This embodiment provides a method for preparing fluosilicic acid for lead electrolysis, and the specific preparation process includes the following steps:

[0058] S1. Provide low-grade fluorosilicic acid, and analyze the components and content of low-grade fluorosilicic acid, and the result is H 2 SiF 6 : 24.09%, HF: 19.75%, H 2 SO 4 : 1.14% (mass percentage, the same below), according to the analysis results, 799.32g of this low-grade fluorosilicic acid was weighed.

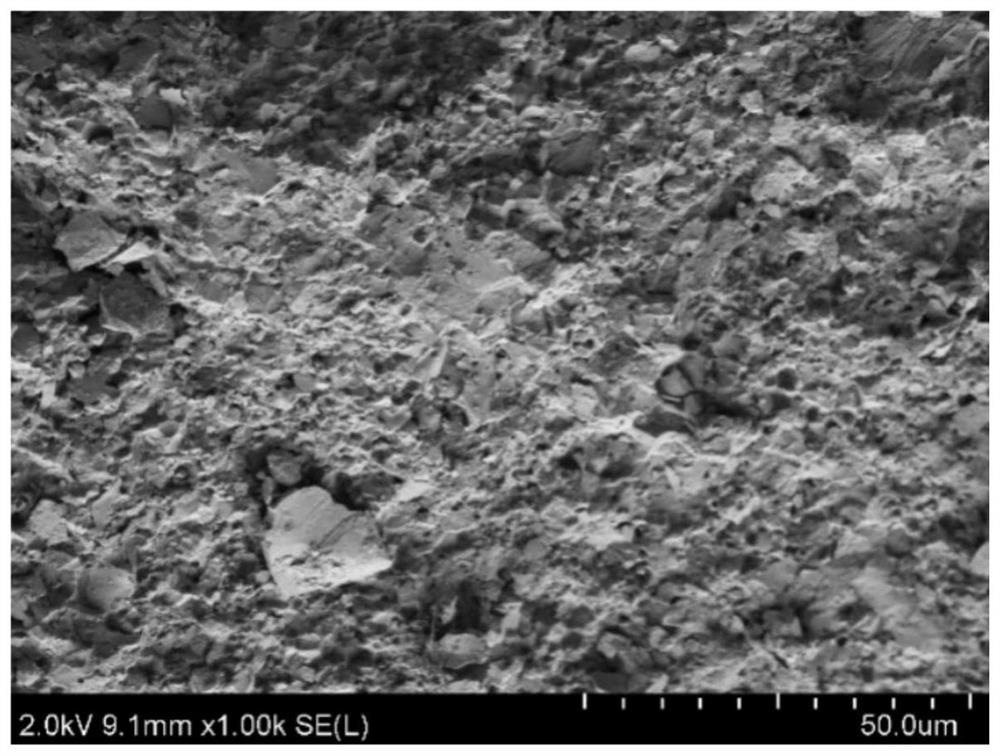

[0059] S2, according to the result in step S1, according to molar ratio (6HF):(SiO 2 )=1:2 Calculate the theoretical amount of quartz sand, and weigh 163.77g of quartz sand according to the molar ratio relationship between the theoretical amount and the actual amount, wherein, the particle diameter of the quartz sand used in this embodiment ranges from 0.5mm to 2mm, and the The crystal morphology of quartz sand is as figure 2 shown.

[0060] Add the quartz sand in the above step to the low-grade f...

Embodiment 2

[0065] This embodiment provides a method for preparing fluosilicic acid for lead electrolysis, and the specific preparation process includes the following steps:

[0066] S1. Provide low-grade fluorosilicic acid, and analyze the result of low-grade fluorosilicic acid as H 2 SiF 6 : 24.09%, HF: 19.75%, H 2 SO 4 : 1.14%, weighed 800.75 g of the low-grade fluorosilicic acid according to the analysis results.

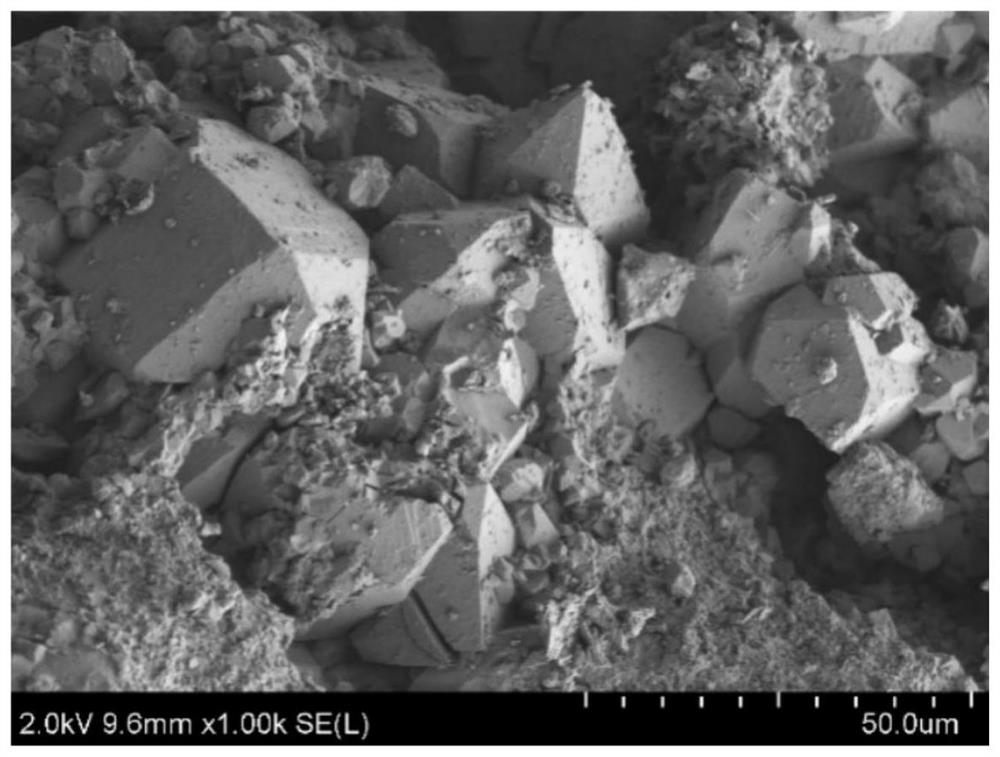

[0067] S2, according to the result in step S1, according to molar ratio (6HF):(SiO 2 )=1:2 to calculate the theoretical amount of quartz sand, and weigh 164.14g of quartz sand according to the molar ratio between the theoretical amount and the actual amount. The quartz sand used in the example is figure 2 The quartz sand with the crystal morphology shown is obtained after calcining at 800°C for 12 hours. The crystal morphology of the quartz sand is as follows image 3 and Figure 4 As shown, it is a hexagonal column with a loose porous structure, a large specific su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com