Preparation process of beta-glucan

A preparation process and glucan technology, applied in the field of preparation technology of beta-glucan, can solve the problems of low purity of finished products, poor use effect, decolorization, large loss of deproteinization steps, etc., and achieve high biological activity and cost. Low, high retention and purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

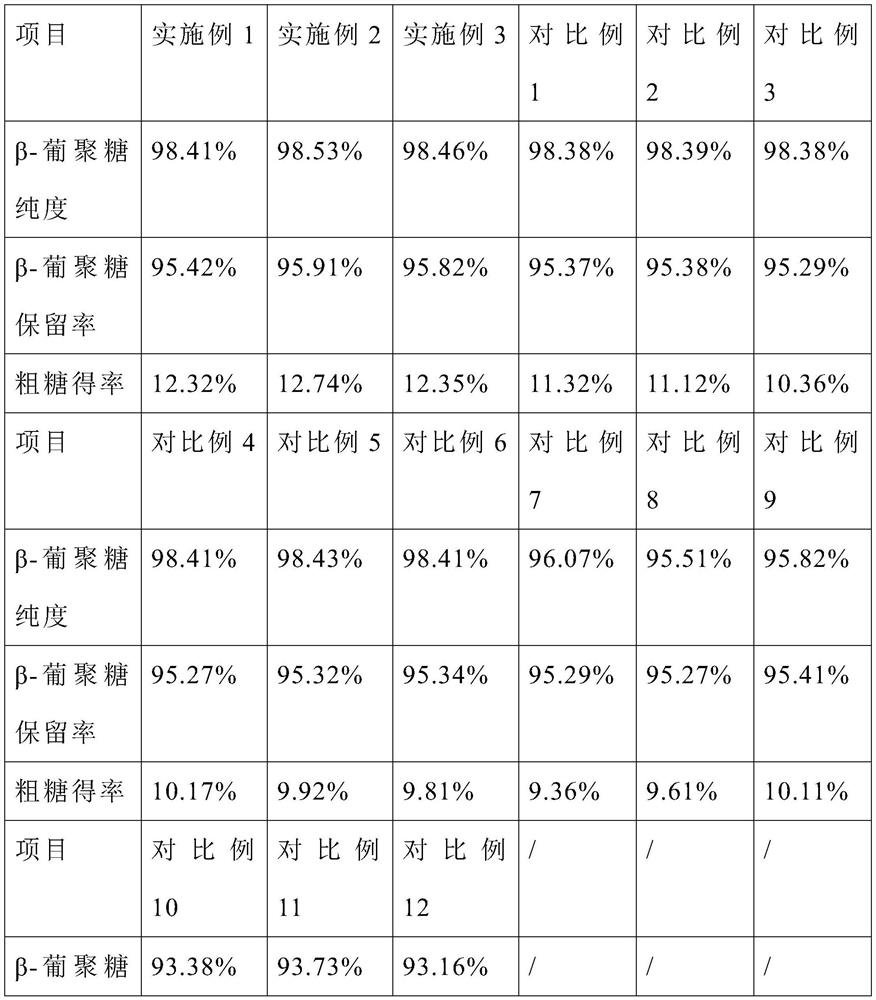

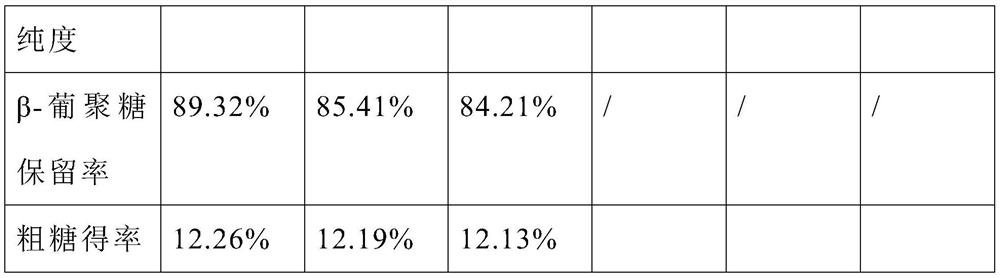

Examples

preparation example Construction

[0045] A preparation process of β-glucan, comprising the following steps:

[0046] S1: strain screening:

[0047] Prepare the strains, carry out the Congo red agar staining method qualitative test respectively, detect the β-1,3-glucanase activity of the strains, carry out screening, and obtain the strains to be cultured, and set aside;

[0048] S2: strain culture;

[0049] Take the strain to be cultured, culture the slant seeds for 7-8 days at a culture temperature of 26-28°C, inoculate them on a plate medium, and cultivate them for 7-8 days under the conditions of 25-30°C and 170-180r / min to obtain a seed liquid;

[0050] S3: Fermentation:

[0051] Take the seed liquid, put it in a fermenter for 7-8 days, and stir at a speed of 100-300r / min to obtain a fermented liquid; add starch debranching enzyme and glucoamylase to the fermenter in sequence after 3-4 days of fermentation in the process, and the temperature is 28-300r / min. Carry out enzymatic hydrolysis at 32°C;

[005...

Embodiment 1

[0060] S1: strain screening:

[0061] Prepare the strains, carry out the Congo red agar staining method qualitative test respectively, detect the β-1,3-glucanase activity of the strains, carry out screening, and obtain the strains to be cultured, and set aside;

[0062] S2: strain culture;

[0063] Take the strain to be cultured, culture the slant seeds for 7 days at a culture temperature of 26°C, inoculate them on a plate medium, and cultivate them for 7 days at 25°C and 170r / min to obtain a seed solution;

[0064] S3: Fermentation:

[0065] Take the seed liquid, put it in a fermenter for 7 days, and stir at a speed of 100r / min to obtain a fermented liquid; add starch debranching enzyme and glucoamylase to the fermenter in sequence after 3 days of fermentation during the process, and carry out enzymatic hydrolysis at a temperature of 28°C ;

[0066] S4: Rough extraction and decolorization:

[0067] The fermentation broth was irradiated with γ-rays, and the irradiation sou...

Embodiment 2

[0074] S1: strain screening:

[0075] Prepare the strains, carry out the Congo red agar staining method qualitative test respectively, detect the β-1,3-glucanase activity of the strains, carry out screening, and obtain the strains to be cultured, and set aside;

[0076] S2: strain culture;

[0077] Take the strain to be cultured, culture the slant seeds for 7 days at a culture temperature of 27°C, inoculate them on a plate medium, and cultivate them for 7 days at 28°C and 175 r / min to obtain a seed liquid;

[0078] S3: Fermentation:

[0079] Take the seed liquid, put it in a fermenter for 7 days, and stir at a speed of 200r / min to obtain a fermented liquid; add starch debranching enzyme and glucoamylase to the fermenter in sequence after 4 days of fermentation during the process, and carry out enzymatic hydrolysis at a temperature of 30°C ;

[0080] S4: Rough extraction and decolorization:

[0081] The fermentation broth was irradiated with γ-rays, and the irradiation sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com