Ultrafine-grained garnet type solid electrolyte powder and preparation method thereof

A solid electrolyte and garnet-type technology, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of unsuitable industrial production, complicated operation, and long cycle, so as to avoid waste, reduce sintering temperature, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

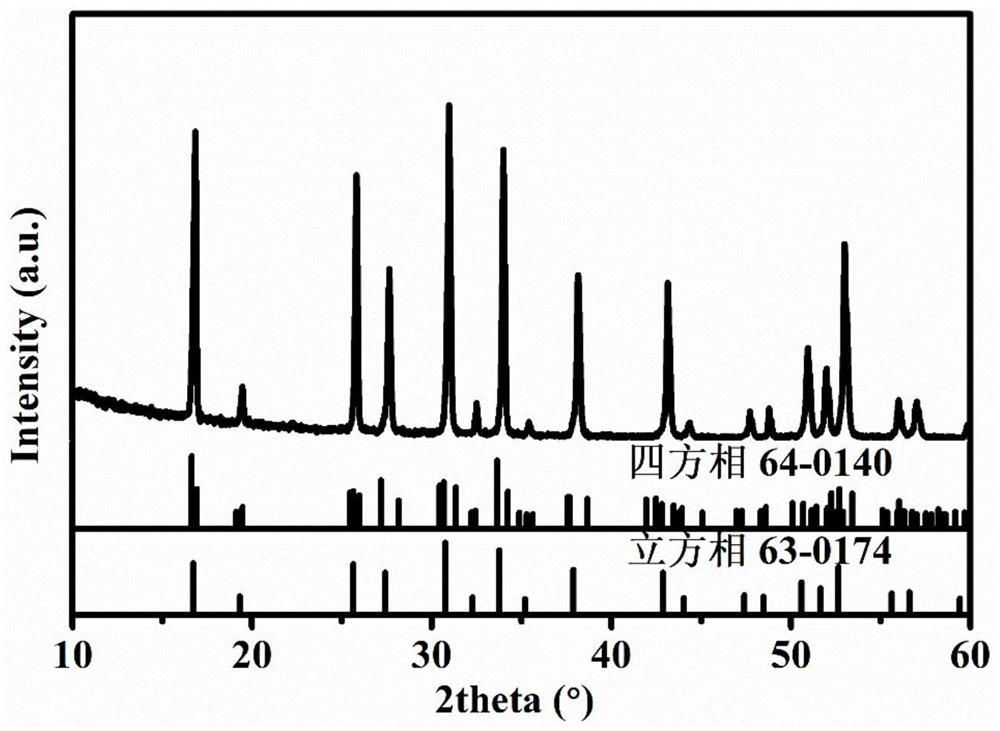

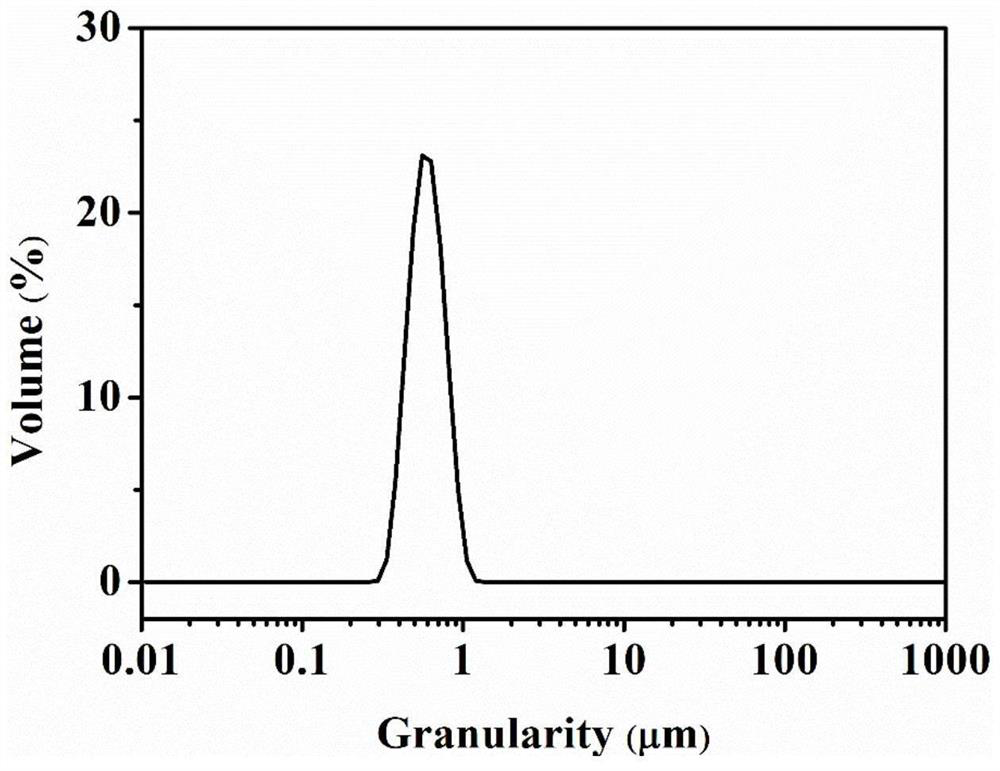

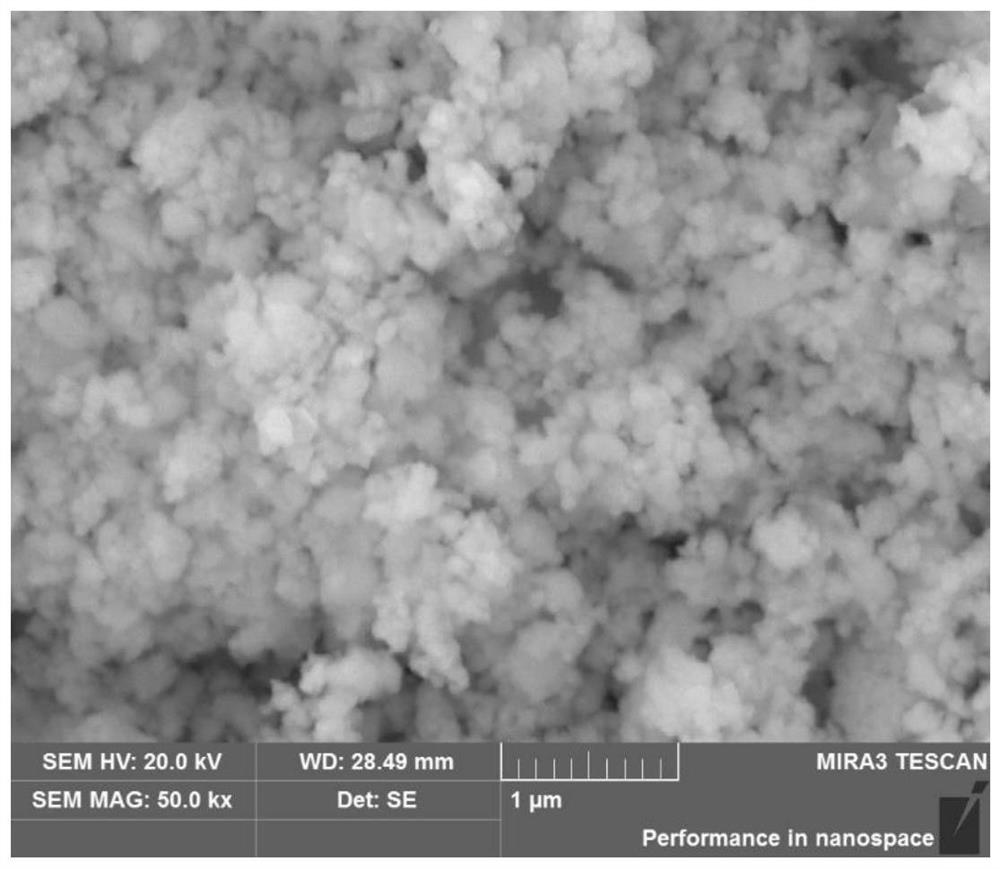

[0055] A garnet-type lanthanum lithium zirconate (LLZO) solid electrolyte powder with ultrafine particle size and a preparation method thereof, the method specifically comprising the following steps:

[0056] (1) Preparation of mixed slurry: weigh the compounds of lithium, lanthanum, zirconium, and doping elements according to a predetermined ratio (for example, taking Nb doping as an example, wherein lithium hydroxide is 6.6 parts, lanthanum oxide is 1.5 parts, oxide 1.6 parts of zirconium, 0.2 parts of niobium oxide, the preparation of L i6.6 La 3 Zr 1.6 Nb 0.4 o 12 powder), and mixed with ball milling solvent and ball milling medium in respective proportions to prepare mixed slurry;

[0057] In (1) of this step, the compound forms of lithium, lanthanum, zirconium and dopant elements include but not limited to oxides, nitrates, carbonates, hydroxides and the like. Preferably, lithium hydroxide, lanthanum oxide, zirconium oxide and niobium oxide are used in this embodime...

Embodiment 1

[0073] Lithium hydroxide, lanthanum oxide, zirconia, and niobium oxide were weighed according to the stoichiometric ratio, wherein 6.6 parts of lithium hydroxide, 1.5 parts of lanthanum oxide, 1.6 parts of zirconia, and 0.2 parts of niobium oxide were used to prepare Li 6.6 La 3 Zr 1.6 Nb 0.4 o 12 Powder. Add the above raw materials into a nylon ball mill jar, add isopropanol with a mass ratio of 1.5:1, and yttrium-stabilized zirconia ball milling media with a mass ratio of 5:1, wherein the diameters of yttrium-stabilized zirconia are 3mm and 6mm, and its mass The ratio is 1:1.4. The mixed raw materials were placed in a planetary ball mill for ball milling, the ball milling speed was 800r / min, and the ball milling time was 6h. The obtained mixed raw material slurry was placed in a blast drying oven, and dried at 70° C. for 20 h to obtain mixed raw material powder. Put the mixed raw material powder in a corundum crucible, vibrate the powder and place it in a muffle furnac...

Embodiment 2

[0076] Lithium hydroxide, lanthanum oxide, zirconia, and niobium oxide were weighed according to the stoichiometric ratio, wherein lithium hydroxide was 6.8 parts, lanthanum oxide was 1.5 parts, zirconia was 1.8 parts, and niobium oxide was 0.1 part, to prepare Li 6.8 La 3 Zr 1.8 Nb 0.2 o 12 Powder. Add the above raw materials into a nylon ball mill jar, add isopropanol with a mass ratio of 1.5:1, and yttrium-stabilized zirconia ball milling media with a mass ratio of 5:1, wherein the diameters of yttrium-stabilized zirconia are 3mm and 6mm, and its mass The ratio is 1:1.4. The mixed raw materials were placed in a planetary ball mill for ball milling, the ball milling speed was 800r / min, and the ball milling time was 6h. The obtained mixed raw material slurry was placed in a blast drying oven, and dried at 70° C. for 20 h to obtain mixed raw material powder. Put the mixed raw material powder in a corundum crucible, place the powder in a muffle furnace after vibration, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com