Environment-friendly anti-collapse plugging drilling fluid as well as preparation method and application thereof

A drilling fluid, environmental protection technology, applied in the field of environmental protection anti-slump plugging drilling fluid and its preparation, can solve the problems of drilling fluid pollution, poor suspension of oil-based drilling fluid, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the present invention, the preparation method of the plugging agent preferably comprises the following steps:

[0038] (1) dissolving polypropylene alcohol in water and stirring evenly, adding epichlorohydrin to it to obtain raw material mixture I;

[0039] (2) Dissolving 2-acrylamide-2-methylpropanesulfonic acid in water, adding sodium hydroxide to control pH = 6-7, then adding acrylamide and mixing evenly to obtain raw material mixture II;

[0040] (3) Add a cross-linking agent to the raw material mixture I, control the cross-linking reaction time to be 1-2 hours, add the raw material mixture II and the initiator during this period, adopt nitrogen protection, and carry out graft copolymerization reaction at 60°C, and the obtained product Dehydration and crushing are carried out in sequence to obtain the plugging agent.

[0041] In the present invention, it is preferred to dissolve polypropylene alcohol in water and stir evenly, and then add epichlorohydrin therein...

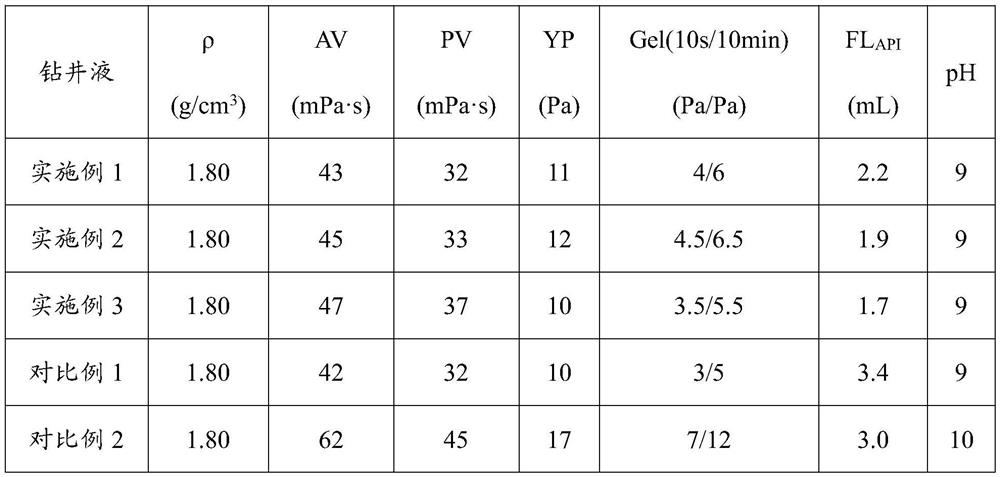

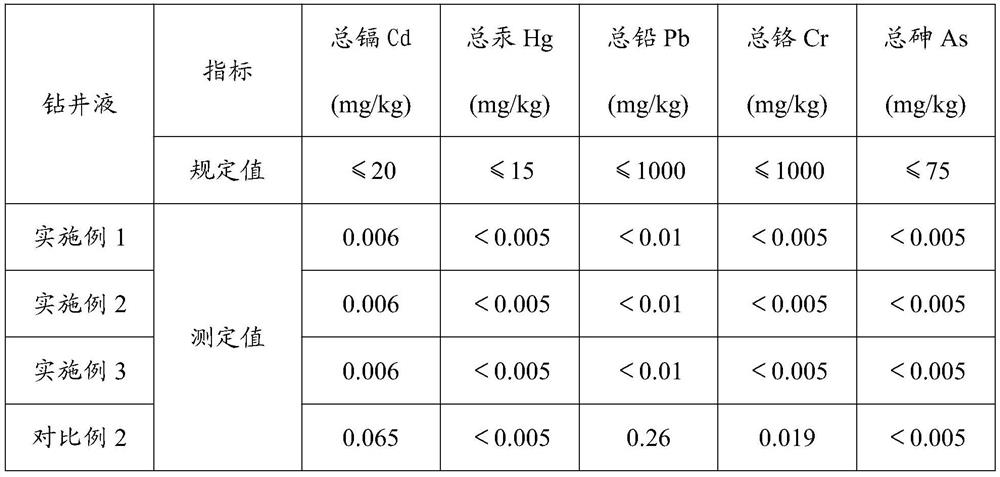

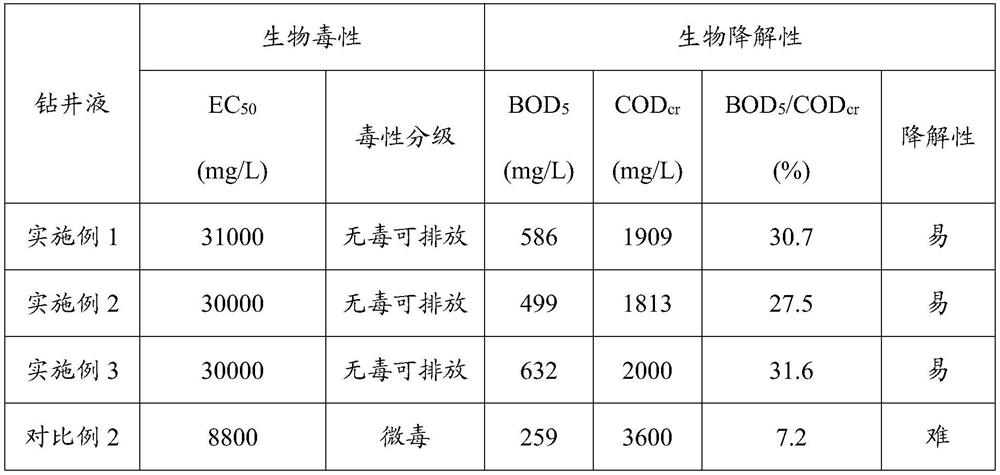

Embodiment 1

[0070] Preparation of plugging agent:

[0071] (1) Dissolve 60 parts of polypropylene alcohol in water and stir evenly, add 30 parts of epichlorohydrin to it to obtain raw material mixture I;

[0072] (2) Dissolve 7 parts of 2-acrylamide-2-methylpropanesulfonic acid in water, add sodium hydroxide to control pH = 6-7, then add 3 parts of acrylamide and mix well to obtain raw material mixture II;

[0073] (3) Add 0.6 part of amide compound to raw material mixture I, then add raw material mixture II, 0.5 part of ammonium persulfate and 0.5 part of benzoyl peroxide, stir evenly, use nitrogen protection, and carry out graft copolymerization at 60 °C reaction, the obtained product is dehydrated and pulverized to obtain a plugging agent.

[0074] Preparation of anti-collapse agent:

[0075] (1) Dissolve 12 parts of the hydrophilic monomer 2-acrylamide-2-methylpropanesulfonic acid in 50 parts of water, add sodium hydroxide to control pH = 6-7, add 24 parts of acrylamide and mix even...

Embodiment 2

[0084] Prepare water-based drilling fluid according to the method of Example 1, the difference is that 100 parts of water; 2 parts of sodium bentonite, 0.3 parts of pH regulator (the mass ratio of sodium hydroxide and sodium carbonate is 1:2), polyanionic fiber 0.5 parts of element, 0.1 part of partially hydrolyzed polyacrylamide, 1.5 parts of carboxymethyl starch, 5 parts of potassium sulfate, 2 parts of polyether diamine, 2 parts of polyether polyol, 3 parts of blocking agent, 0.6 part of anti-slump agent, Xanthan gum 0.12 parts, density 4.2g / cm 3 And barite with a purity of 95%, adjust the density of the drilling fluid to 1.80g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com