Preparation method and application of nitrogen-doped graphene-loaded carbon nitride composite material for activating persulfate

A technology of nitrogen-doped graphene and activated persulfate, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

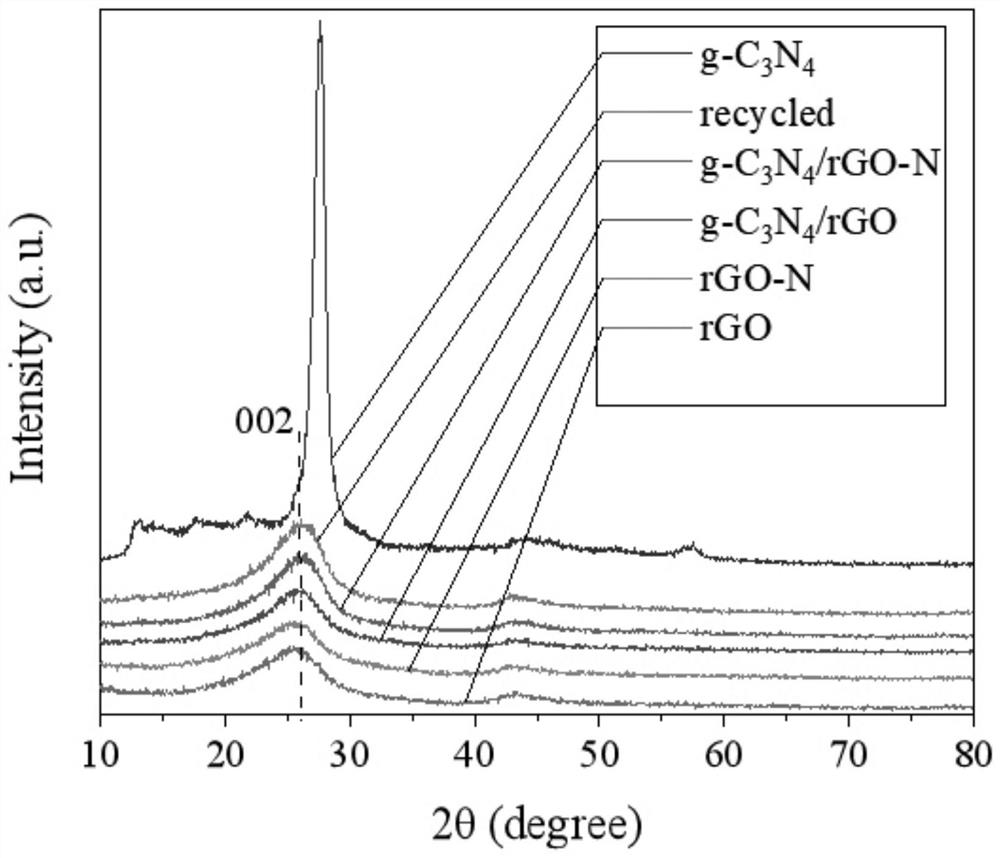

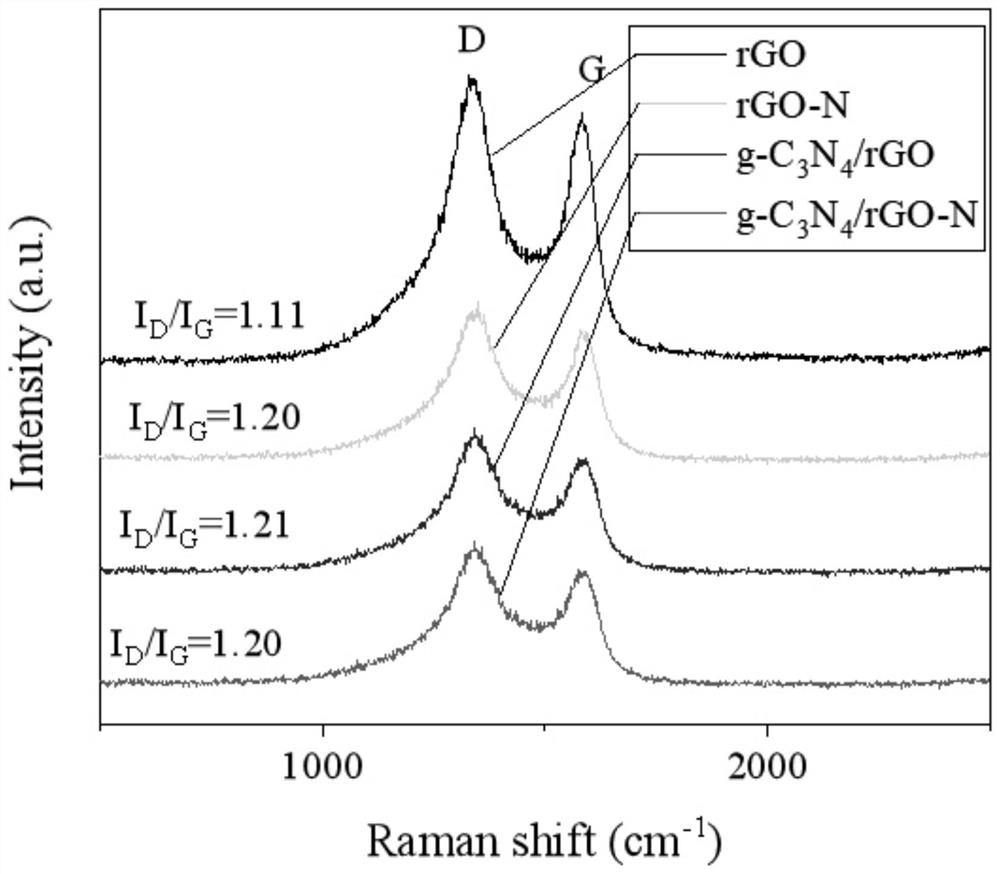

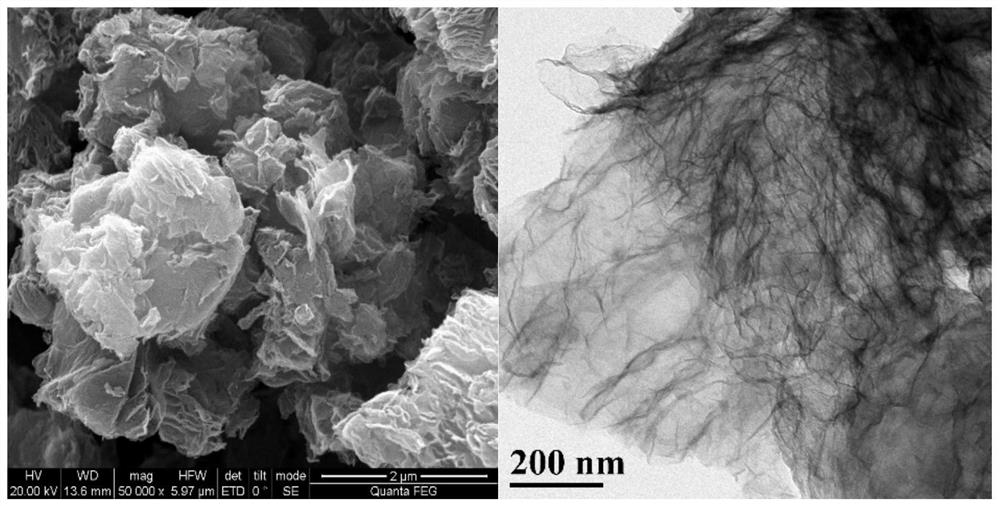

[0033] The preparation method of the nitrogen-doped graphene-loaded carbon nitride composite material of activated persulfate comprises the following steps: S1, raw material, select commercial graphene, melamine, urea; S2, mixing, evenly mix commercial graphene, melamine, urea ; S3, calcining, the commercial graphene, melamine, and urea mixed uniformly in step S2 are placed in a tube furnace under a nitrogen atmosphere, and the temperature is controlled at 500-600°C for calcination, and the heating rate is controlled at 3-8°C / min , constant temperature for 220-250min, and cooled to room temperature under nitrogen atmosphere, the nitrogen-doped graphene-loaded carbon nitride composite material g-C with activated persulfate was obtained. 3 N 4 / rGO-N. where g-C 3 N 4 / rGO-N is non-toxic and cheap, and can be directly synthesized by thermal shrinkage of nitrogen-rich precursors such as melamine and dicyandiamide, and the acquisition method is relatively easy.

[0034] Wherein...

Embodiment 1

[0037] The preparation of the nitrogen-doped graphene-loaded carbon nitride composite material of activated persulfate is as follows:

[0038] Take 5g rGO, 5g melamine, and 5g urea, mix them evenly, put them in a 20ml corundum crucible with a cover, seal it with aluminum foil, put it into a 2 Calcined at different temperatures in a tube furnace for 30 min. The calcination time can be selected as any time point from 220 to 250 min, the preferred calcination time is 220, 240, 250 min, and the optimum time is 240 min. When the calcination time is less than 220min or greater than 250min, it will cause the preparation of g-C 3 N 4 / rGO-N caused damage to part of the graphite crystal structure. The heating rate can be controlled at any rate of 3-8°C / min, such as 3, 5, and 8°C / min. When the heating rate is lower than 3°C / min, the entire preparation time is relatively long, and the heating rate is greater than 8°C / min, which will cause uneven temperature changes inside and outsid...

Embodiment 2

[0042] The removal test of the dye AO7 by the nitrogen-doped graphene-supported carbon nitride composite material activated persulfate is as follows:

[0043] The nitrogen-doped graphene-loaded carbon nitride composite material with activated persulfate prepared in Example 1 was selected as a raw material to carry out comparative tests successively.

[0044] Among them, in the 50mg / LAO7 solution, add 20mg / Lg-C 3 N 4 / rGO-N and 307mg / LPMS, every once in a while, sampling, filtering to remove g-C 3 N 4 / rGO-N, the reaction was terminated by adding methanol, and the concentration change of AO7 in the reaction solution was analyzed by ultraviolet spectrophotometer.

[0045] As a comparison, conventional rGO and its N-doped samples or classical metal catalysts (Co 3 o 4 and Fe 3 o 4 ) as a catalyst, other conditions are the same as above.

[0046] Or add g-C alone 3 N 4 / rGO-N, no PMS, other conditions are the same as above.

[0047] Add PMS alone without g-C 3 N 4 / rG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com