High-hydroxyl acrylic emulsion with quick drying and long working life and synthesis method thereof

A technology of high-hydroxy acrylic acid and methyl methacrylate, applied in the field of polymer chemistry, can solve the problem that high-hydroxy acrylic emulsion cannot have both fast drying and long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

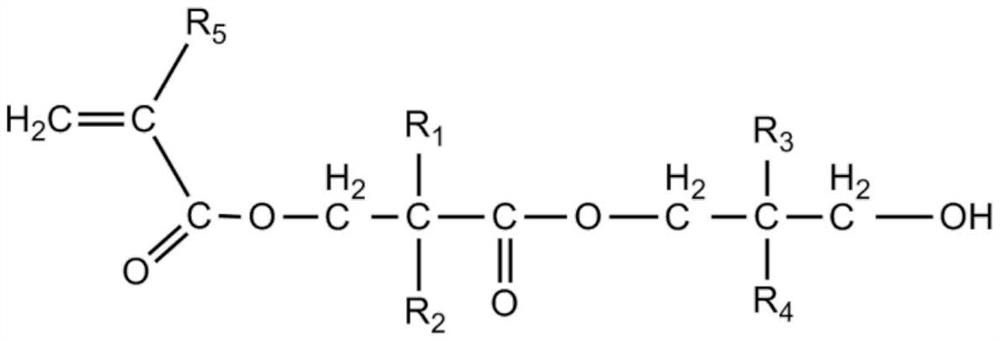

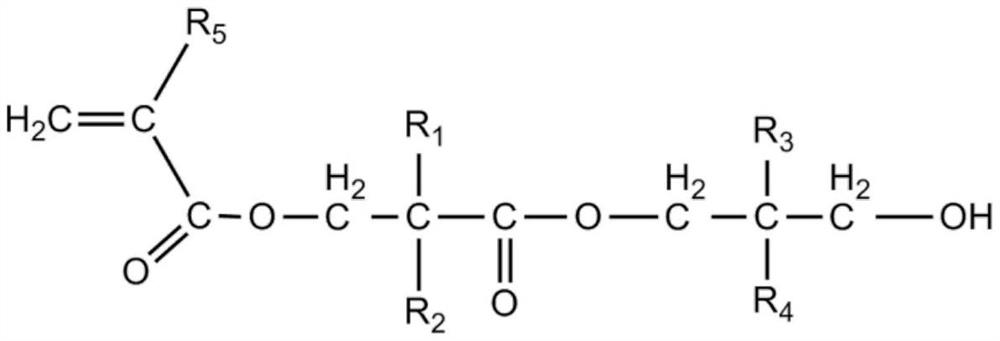

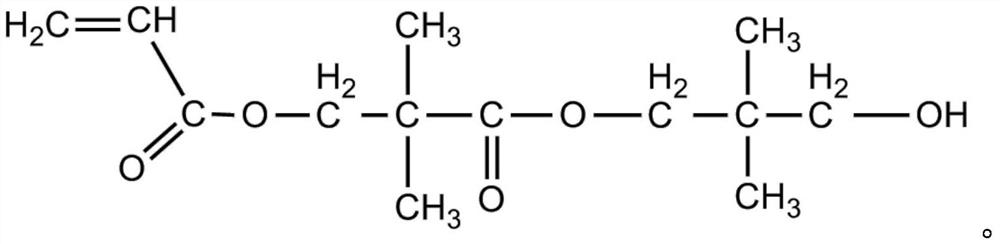

[0049] Example 1 Synthesis of Neopentyl Glycol Monoester of Hydroxypivalate Monoacrylate

[0050] The synthetic method of hydroxypivalic acid neopentyl glycol monoester monoacrylate of the present embodiment comprises the following steps: 2g acrylic acid and 25g hydroxypivalic acid neopentyl glycol monoester are dropped into the reactor, then drop into 0.3g p-toluenesulfonate Acid and 0.1g hydroquinone, start stirring, heat up to 80°C, vacuum degree 0.06-0.04MPa, homogeneous esterification reaction, azeotropic distillation, the generated water is received by the condenser, water separator and water phase The organic phase is returned to the top of the rectification tower to obtain a crude reaction solution, which is added to the phase separation tank, and a mixed liquid of xylene and water is added (the mass ratio of xylene to water is 5:1) Extraction is carried out, and the aqueous phase and the organic phase are obtained by the extraction, and the aqueous phase is passed i...

Embodiment 2

[0054] The raw materials and consumption of the high hydroxyl acrylic emulsion of this embodiment are shown in Table 1.

[0055] Table 1

[0056] raw material Dosage (g) Methyl methacrylate 40 Styrene 10 acrylic acid 1 n-butyl acrylate 10 Neopentyl glycol monohydroxypivalate monoacrylate 38 Ammonium persulfate 0.5 OP-10 1 pH adjuster ammonia water to pH7 Deionized water 150

[0057] The synthetic method of present embodiment high hydroxyl acrylic acid emulsion comprises the following steps:

[0058] ① Mix 0.8g of emulsifier OP-10, 80g of deionized water and selected quality methyl methacrylate, styrene, acrylic acid, n-butyl acrylate, hydroxypivalic acid neopentyl glycol monoacrylate Add it to the pre-emulsification tank, and at room temperature, continue to stir at a stirring rate of 500rpm for 15 minutes to carry out pre-emulsification to obtain a pre-emulsion;

[0059] ②Add 0.2g of emulsifier OP-10 and ...

Embodiment 3

[0065] The raw materials and consumption of the high hydroxyl acrylic emulsion of this embodiment are shown in Table 2.

[0066] Table 2

[0067] raw material Dosage (g) Methyl methacrylate 23 Styrene 20 acrylic acid 1 n-butyl acrylate 15 Neopentyl glycol monohydroxypivalate monoacrylate 37 potassium persulfate 0.5 Sodium dodecyl sulfate 1 pH adjuster ammonia water to pH7 Deionized water 150

[0068] The synthetic method of present embodiment high hydroxyl acrylic acid emulsion comprises the following steps:

[0069] ① Mix 0.8g of emulsifier sodium lauryl sulfate, 80g of deionized water and selected quality methyl methacrylate, styrene, acrylic acid, n-butyl acrylate, neopentyl glycol monohydroxy pivalate An acrylate was added to the pre-emulsification tank, and at room temperature, the stirring rate was 500 rpm for 15 minutes to carry out pre-emulsification to obtain a pre-emulsion;

[0070] ②Add 0.2g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com