Method for full resource utilization of red mud

An all-resource, red mud technology, applied in chemical instruments and methods, preparation/treatment of rare earth metal compounds, iron oxide, etc., can solve the problems of large specific surface area, lack, low market acceptance, etc., and achieve simple process and low cost Low, easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

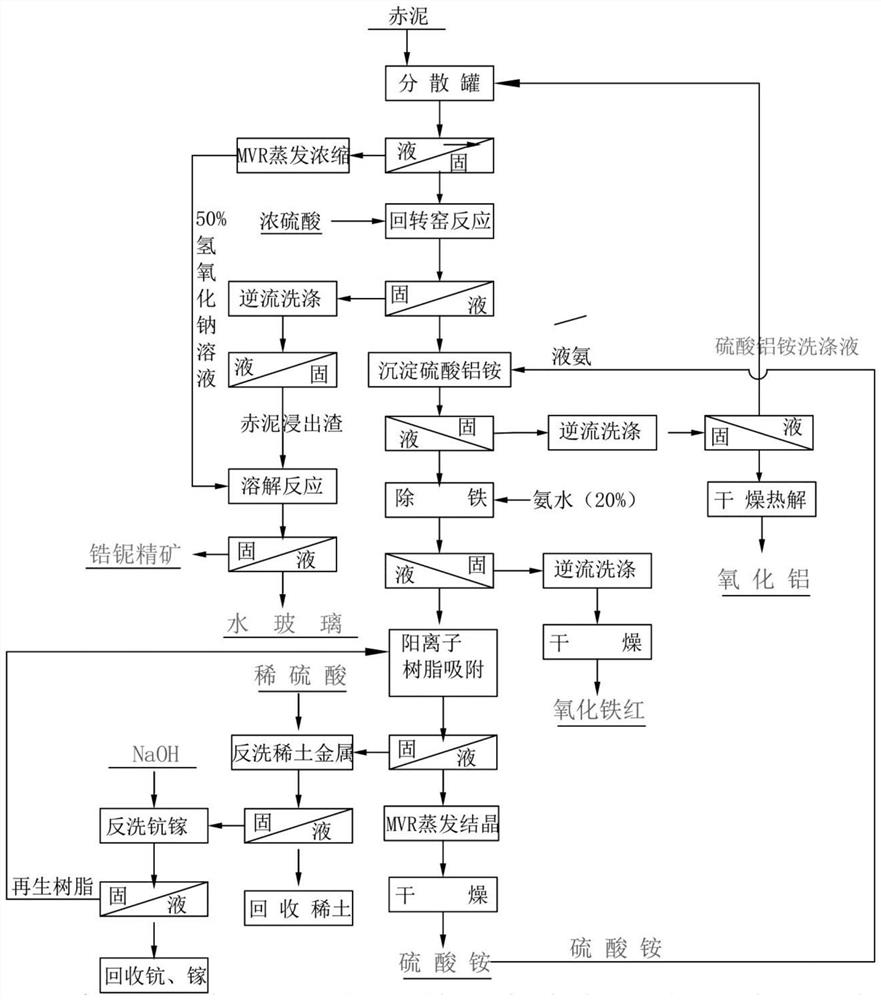

Image

Examples

Embodiment 1

[0017] A method for full resource utilization of red mud, specifically comprising the following steps:

[0018] 1) Washing red mud to recover sodium hydroxide: After adding water to the red mud in the slag warehouse, it is finely crushed by a disperser and then pumped into the washing system of a CCD thickener. Sodium hydroxide is returned to the aluminum plant for use;

[0019] 2) Concentrated acid rotary kiln stirring and leaching red mud washing slag: According to 0.8 times the molar amount of chemical elements in red mud that can react with sulfuric acid, add 50% sulfuric acid to the rotary kiln with exhaust gas recovery and purification system lined with anti-corrosion ceramic tiles Internal mixing reaction for 1 hour, so that sulfuric acid and red mud are mixed evenly in the rotary kiln. The reaction time is 1-3 hours. After the leaching reaction is completed, the slurry after the reaction is dissolved with water or slag washing liquid, and then the solid-liquid thickene...

Embodiment 2

[0026] A method for full resource utilization of red mud, specifically comprising the following steps:

[0027] 1) Washing red mud to recover sodium hydroxide: After adding water to the red mud in the slag warehouse, it is finely crushed by a disperser and then pumped into the washing system of a CCD thickener. Sodium hydroxide is returned to the aluminum plant for use;

[0028] 2) Concentrated acid rotary kiln stirring and leaching red mud washing slag: According to 1.5 times the molar amount of chemical elements in red mud that can react with sulfuric acid, add 98% sulfuric acid in the rotary kiln with exhaust gas recovery and purification system lined with anti-corrosion ceramic tiles Internal mixing reaction for 3 hours, so that sulfuric acid and red mud are mixed evenly in the rotary kiln. The reaction time is 3 hours. After the leaching reaction is completed, the slurry after the reaction is dissolved with water or slag washing liquid, and then the solid-liquid separatio...

Embodiment 3

[0035] A method for full resource utilization of red mud, specifically comprising the following steps:

[0036] 1) Washing red mud to recover sodium hydroxide: After adding water to the red mud in the slag warehouse, it is finely crushed by a disperser and then pumped into the washing system of a CCD thickener. Sodium hydroxide is returned to the aluminum plant for use;

[0037] 2) Concentrated acid rotary kiln stirring and leaching red mud washing slag: According to 1.2 times the molar amount of chemical elements in red mud that can react with sulfuric acid, add 80% sulfuric acid in the rotary kiln with exhaust gas recovery and purification system lined with anti-corrosion ceramic tiles Internal mixing reaction for 2 hours, so that sulfuric acid and red mud are mixed evenly in the rotary kiln, the reaction time is 2 hours, after the leaching reaction is completed, the slurry after the reaction is dissolved with water or slag washing liquid, and then the solid-liquid separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com