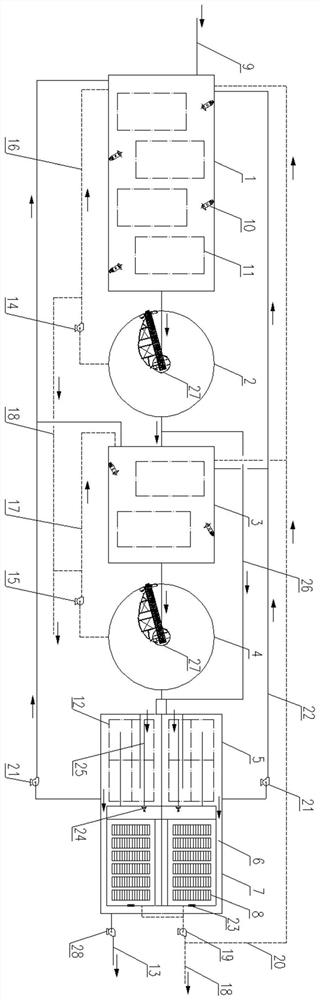

Device and process for recycling high-hardness nitrate wastewater

A nitrate and high hardness technology, applied in water softening, aerobic and anaerobic process treatment, water aeration, etc., can solve problems such as high calcium hardness, blockage, and high difficulty in operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0095] High hardness nitrate wastewater from a solar cell, raw water NO 3 -N is 360mg / L, Ca ion is between 540-1200mg / L, waste water enters the two-stage pulse separation device of the present invention + biochemical membrane tank integration device, denitrification, denitrification and decalcification are carried out in the denitrification pulse tank, and at the same time The denitrification pulse tank is equipped with an annular aeration tube to promote the CO produced by denitrification. 3 2- Alkalinity and Ca ions form crystal particles, and the biochemical sludge and calcium-containing sludge are separated in the separation tank to achieve the purpose of denitrification and calcium removal. After being treated by the process device of the present invention, NO 3 -N is 10mg / L, Ca ion effluent is 20mg / L, the removal rate exceeds 95%, and the produced water meets the reuse water standard.

[0096] The invention can avoid the calcification of activated sludge in the bioche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com