Underfill adhesive with high thermal conductivity and preparation method thereof

A technology of bottom filling glue and high thermal conductivity, which is applied in the direction of heat exchange materials, chemical instruments and methods, adhesives, etc., can solve the problem of limited improvement of thermal conductivity, so as to promote thermal conductivity, facilitate electronic conduction, and smooth conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

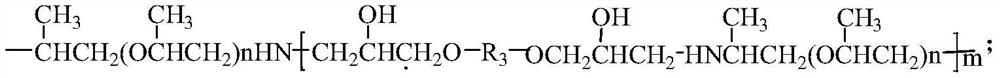

[0030] The preparation technology of this diamine type benzoxazine resin is as follows:

[0031] In the first step, diamine monomer, phenolic compound and paraformaldehyde are added into the reaction vessel, and the molar ratio of diamine monomer, phenolic compound and paraformaldehyde is (1~1.2):(2~2.4): (4~4.4); Simultaneously, add xylene as reaction solvent;

[0032] In the second step, keep stirring at a temperature of 80-150° C. for 4-15 hours to carry out Mannich reaction (Mannich reaction), and cool to room temperature after the reaction;

[0033] In the third step, add ethanol, wash, filter, and vacuum-dry the precipitate in sequence to obtain a crude product; dissolve the crude product in dichloromethane, add 1mol / L sodium hydroxide solution for alkali washing, and then wash with deionized water , separation, adding anhydrous sodium sulfate to the organic layer, standing for 24 hours, and filtering, the filtrate was removed by rotary evaporation to remove the organic...

Embodiment 1

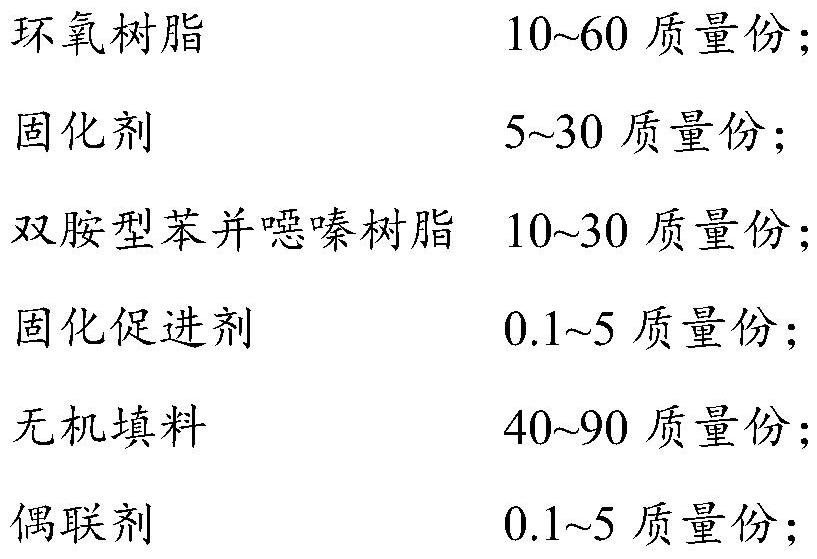

[0037] Prepare the underfill according to the following ratio:

[0038]

[0039] The preparation method is as follows: after mixing the above raw materials uniformly by weight, grind them three times on three rollers, roll them into a paste, and then carry out vacuum defoaming to obtain the filling glue of the embodiment.

Embodiment 2

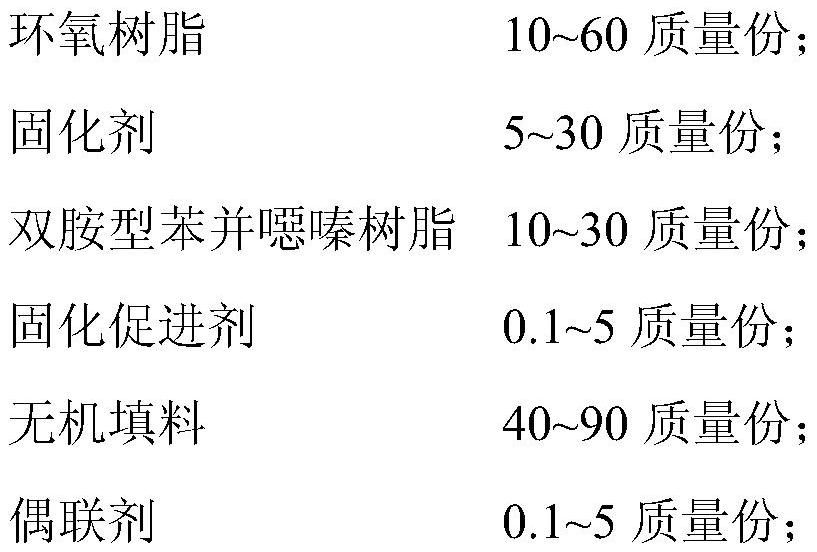

[0041] Prepare the underfill according to the following ratio:

[0042]

[0043]

[0044] Refer to Example 1 for the preparation method of the underfill in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com