Method for producing high-activity antibacterial peptide by fermenting with lactobacillus plantarum

A high-activity technology of Lactobacillus plantarum, applied in the biological field, can solve the problems of industrialized production of antimicrobial peptides, achieve good industrialized production potential, and increase output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Determination of Antimicrobial Peptide Activity of Lactobacillus plantarum CGMCC5297

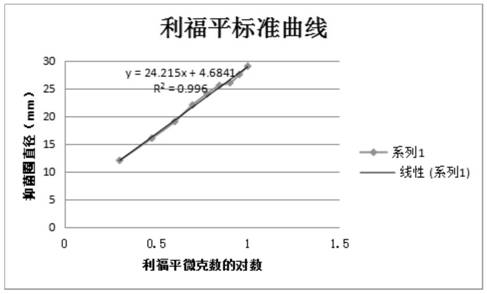

[0016] 1. Drawing of rifampicin standard potency curve

[0017] Using rifampicin as a control, a standard curve of rifampicin was made, and the antibacterial potency of Lactobacillus plantarum CGMCC No 5297 was defined by the titer of rifampicin standard substance with the same antibacterial effect on Listeria monocytogenes . In the potency detection plate, add respectively 2ug / ml, 3ug / ml, 4ug / ml, 5ug / ml, 6ug / ml, 7ug / ml, 8ug / ml, 9ug / ml, rifampicin of 10ug / ml (GENE company , item number: 19-1059) standard item, take Listeria monocytogenes CVCC1595 as indicator bacteria, bacterial concentration is that 107cfu / ml connects in the LB medium that agar content is 0.8%. Add 100ul to each Oxford cup, diffuse at 4°C for 24 hours, and incubate at 30°C in the dark for 24 hours. Take the logarithmic value of rifampicin micrograms as the abscissa, and the diameter of the antibacterial zone as the...

Embodiment 2

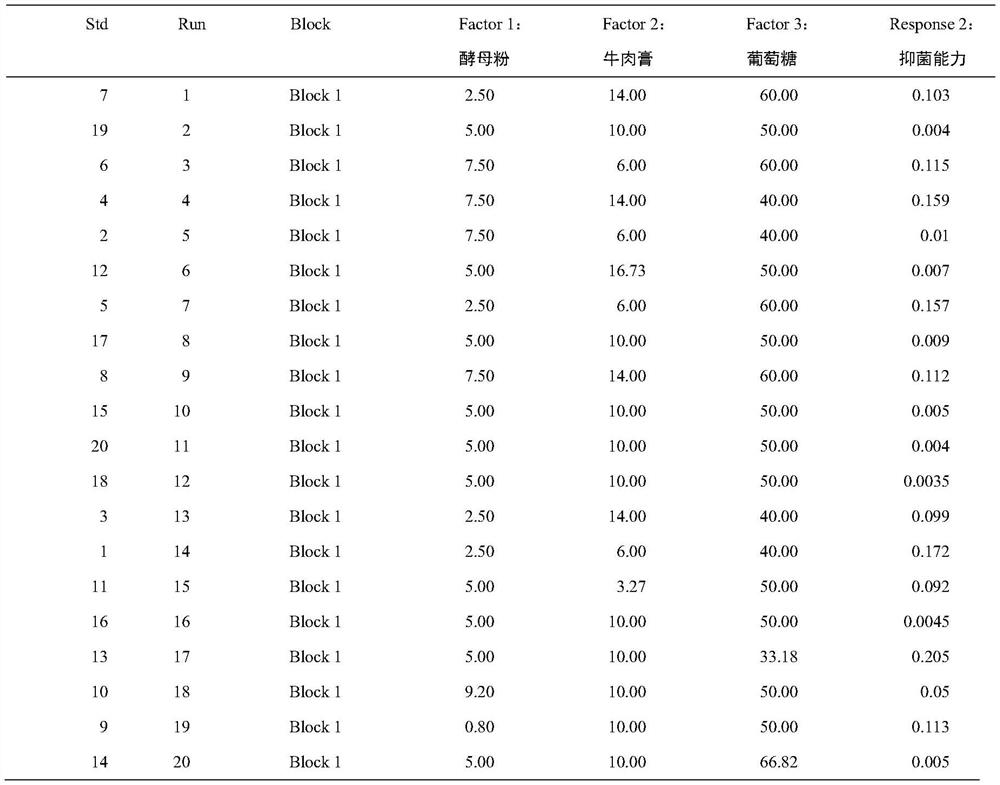

[0022] Optimizing Antimicrobial Peptide Production Medium

[0023] 1. Optimize the carbon and nitrogen sources in the medium

[0024] The remaining components and contents of MRS in the fermentation medium were unchanged, and eight glucose, sucrose, lactose, whey, cornstarch, and molasses were selected as carbon sources with a concentration of 20g / L to determine the appropriate carbon source, and the best The concentration of the carbon source is optimized. The optimization results show that glucose is the optimal carbon source for producing antimicrobial peptides, and the optimal concentration of glucose fermentation to produce Lactobacillus plantarum antimicrobial peptides is 40g / L.

[0025] With 40g / L glucose as the best carbon source, soybean cake powder, yeast extract, corn steep liquor, yeast powder, and tryptone were selected as nitrogen sources with a concentration of 20g / L, and the appropriate nitrogen source was determined, and its concentration was determined. opt...

Embodiment 3

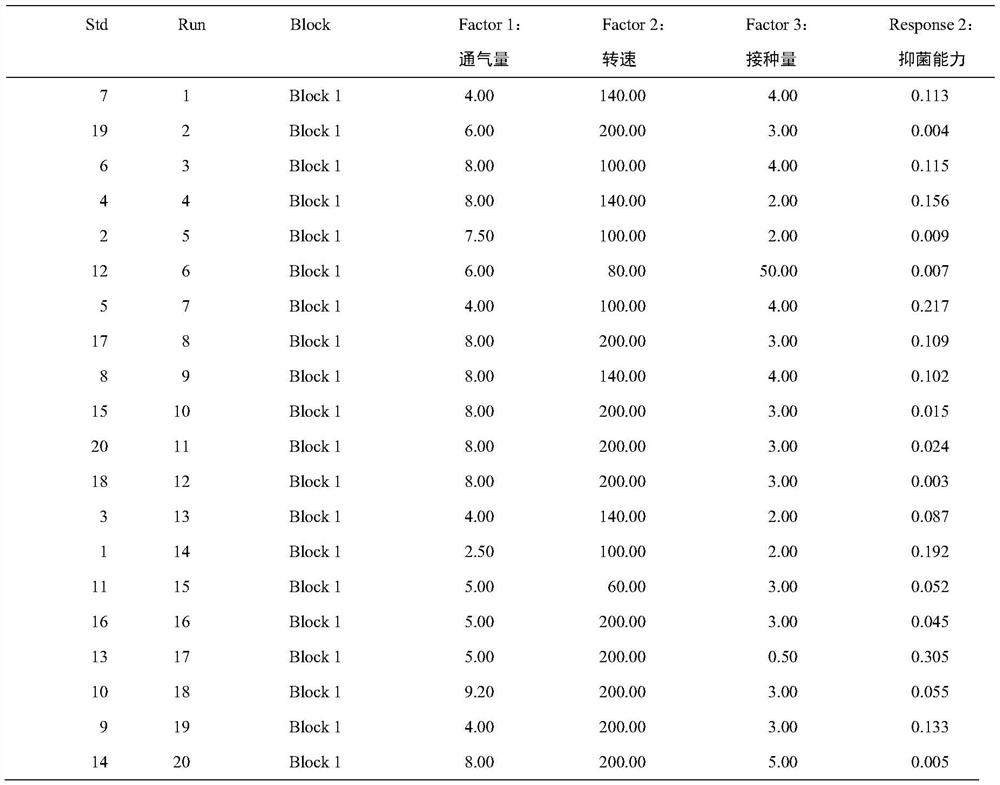

[0036] Optimizing fermentation conditions with LiFlus GM automatic hexaplex fermenter

[0037] The optimal medium was used for the fermentation of Lactobacillus plantarum antimicrobial peptides, and the LiFlus GM automatic hexaplex fermenter was used to optimize the inoculation volume, ventilation volume, and rotational speed. The experimental results are shown in Table 2. LiFlus GM automatic hexaplex fermenter can realize simultaneous fermentation of six tanks. For optimization experiments of fermentation conditions, this equipment can achieve efficient and accurate results. From the analysis of the extreme R value of the experimental results, it can be seen that the order of the influence of the three factors on the fermentation of the Lactobacillus plantarum CGMCC5297 antimicrobial peptide is: A (aeration volume) > C (inoculum volume) > B (rotational speed). The optimal combination of fermentation conditions is: aeration ratio 5.5vvm, rotation speed 120r / min, inoculum size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com