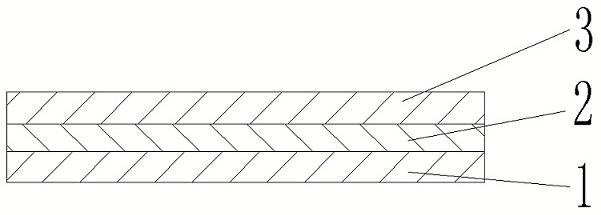

Oil-resistant isolation primer, and preparation method, use method and construction method thereof, and obtained color-exposed composite waterproof coating layer

An oil-resistant and primer-resistant technology, used in coatings, primers, roof insulation materials, etc., can solve problems such as discoloration of colored surfaces, and achieve the effect of prolonging discoloration time, isolating oil well, and delaying discoloration of surface layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Oil-resistant isolation primer:

[0040] The oil-resistant isolation primer is composed of the following components: 70 kg of anionic neoprene latex with a solid content of 58%, 5Kg of zinc oxide, 10Kg of talcum powder, 5Kg of fumed silica, 0.15Kg of sodium bentonite, 0.3Kg of ammonium salt dispersant, Alkylphenol polyoxyethylene ether wetting agent 0.1Kg, silicone defoamer 0.4Kg, antioxidant 1010 0.5Kg, UV-292 0.5Kg, 2-n-octyl-4-isothiazolin-3 ketone 0.1Kg, 0.1Kg of 2-amino-2methyl-1-propanol, 0.1Kg of alkali swelling thickener, 10Kg of deionized water.

[0041] 2. A preparation method for an oil-resistant isolation primer, comprising the following steps:

[0042] Step 1): Add the above-mentioned ammonium salt dispersant, alkylphenol polyoxyethylene ether wetting agent, 2 / 3 silicone defoamer, sodium bentonite, fumed silica, zinc oxide, talcum powder into the deionized water , Antioxidant 1010, UV-292 and 2-n-octyl-4-isothiazolin-3-one, high-speed grinding until ...

Embodiment 2

[0053] 1. Oil-resistant isolation primer:

[0054] The oil-resistant isolation primer is composed of the following components: 80 kg of anionic neoprene latex with a solid content of 50%, 4Kg of zinc oxide, 5Kg of talcum powder, 4Kg of nano-silica colloid, 0.15Kg of sodium bentonite, and 0.3kg of ammonium salt dispersant , Alkylphenol polyoxyethylene ether wetting agent 0.1Kg, silicone defoamer 0.4Kg, antioxidant 1010 0.5Kg, UV-292 0.5Kg, 2-n-octyl-4-isothiazoline-3 Ketone 0.1Kg, 2-amino-2methyl-1-propanol 0.1Kg, alkali swelling thickener 0.1Kg, deionized water 8Kg.

[0055] 2. Preparation method of oil-resistant isolation primer:

[0056] Step 1): Add the above-mentioned ammonium salt dispersant, alkylphenol polyoxyethylene ether wetting agent, 2 / 3 silicone defoamer, sodium bentonite, zinc oxide, nano-silica colloid, talc into deionized water powder, antioxidant 1010, UV-292 and 2-n-octyl-4-isothiazolin-3-ketone, and grind at high speed until the dispersion is uniform to ...

Embodiment 3

[0065] 1. Oil-resistant isolation primer:

[0066] The oil-resistant isolation primer is composed of the following components: 60 kg of anionic neoprene latex with a solid content of 50%, 5Kg of zinc oxide, 5Kg of talcum powder, 5Kg of graphene, 5Kg of precipitated silica, 0.15Kg of sodium bentonite, ammonium Salt dispersant 0.45kg, alkylphenol polyoxyethylene ether wetting agent 0.15Kg, silicone defoamer 0.5Kg, antioxidant 1076 0.5Kg, UV-2920.5Kg, 2-methyl-4-isothiazoline -3 ketone (MIT) 0.15Kg, 2-amino-2 methyl-1-propanol 0.15Kg, alkali swelling thickener 0.1Kg, deionized water 20Kg.

[0067] 2. Preparation

[0068] Step 1): Add the above-mentioned ammonium salt dispersant, alkylphenol polyoxyethylene ether wetting agent, 2 / 3 silicone defoamer, sodium bentonite, precipitated silica, zinc oxide, talc into deionized water Powder, graphene, antioxidant 1076, UV-292 and 2-methyl-4-isothiazolin-3-one (MIT), high-speed grinding until uniform dispersion, to obtain a slurry;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com