Photocureable coating containing hyperbranched polyester ether type photocureable resin and preparation method of photocureable coating

A technology of hyperbranched polyester and light-curing coatings, applied in epoxy resin coatings, coatings, etc., can solve problems such as low shrinkage adhesion, achieve excellent acid and alkali resistance, high reactivity, excellent rigidity and mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A hyperbranched polyester ether type light-curable resin, and its preparation method includes the following steps:

[0027] Combine 3,5-dihydroxybenzoic acid (10.00g, 64.9mmol), 1,4-dibromobutane (14.006g, 64.9mmol), potassium carbonate (21.56g, 155.75mmol) and N,N'-dimethyl Methyl formamide (120 mL) was added to the reactor, the reaction system was heated to 80°C, and reacted for 24 hours under mechanical stirring.

[0028] Then the temperature of the reaction system was lowered to 30°C, cesium carbonate (25.37g, 77.85mmol), 4-chloromethylstyrene (9.905g, 64.9mmol) and N,N'-dimethylformamide (20mL) were added, Continue to react at 40°C for 24h. After centrifugal desalting, rotary evaporation and concentration, deionized water precipitation and freeze-drying, the hyperbranched polyester ether type light curing resin HBPEE1 is obtained.

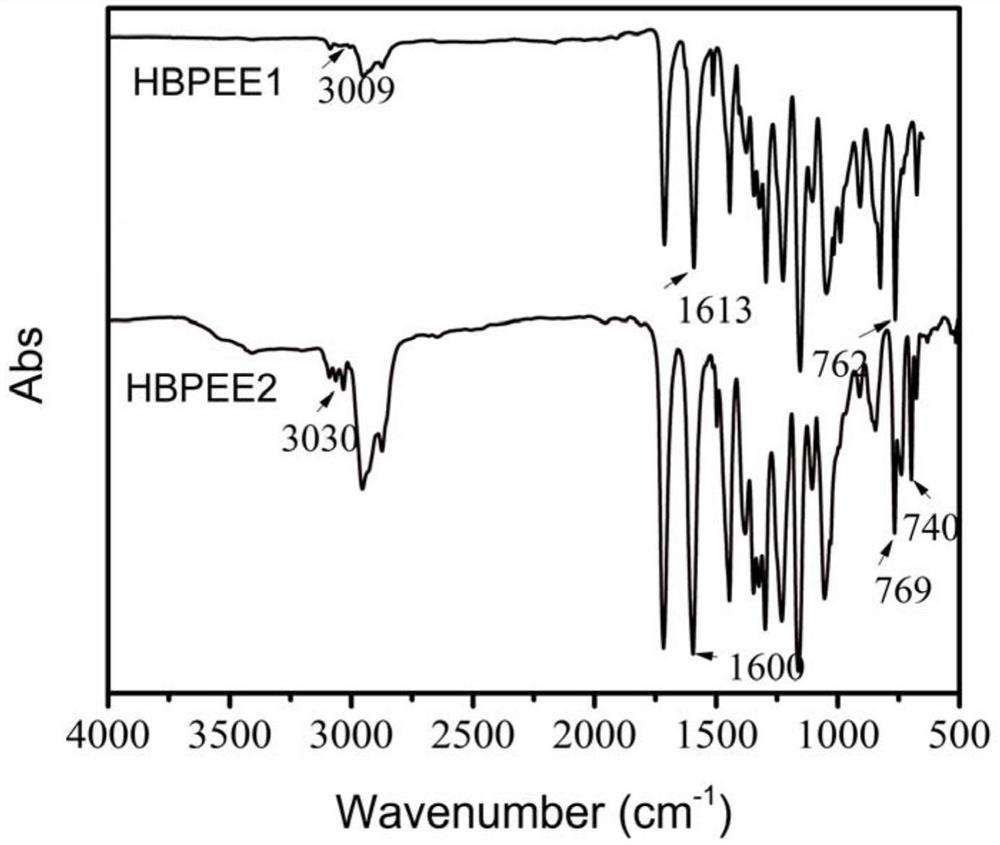

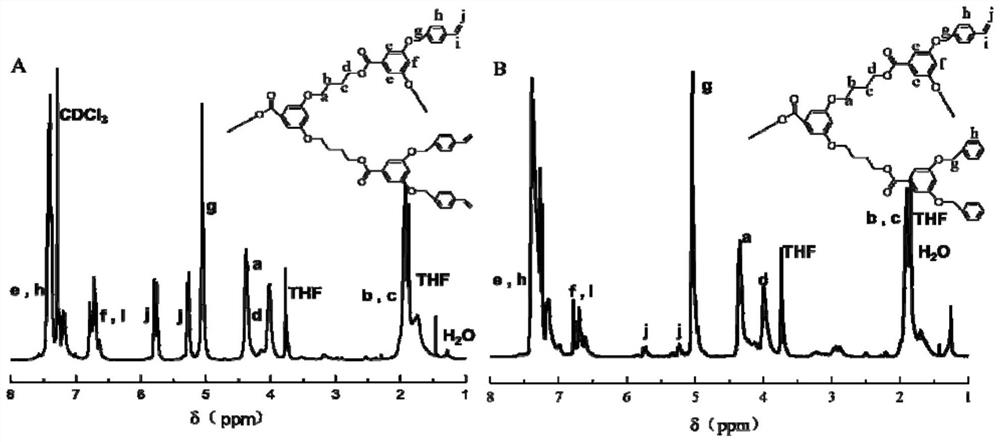

[0029] The infrared absorption spectrum of the hyperbranched polyester ether type photocurable resin HBPEE1 obtained in Example 1 is as fol...

Embodiment 2

[0031] A hyperbranched polyester ether type light-curing resin, and its preparation method includes the following steps:

[0032] Combine 3,5-dihydroxybenzoic acid (20.00g, 129.8mmol), 1,4-dibromobutane (28.02g, 129.8mmol), potassium carbonate (43.10g, 311.5mmol) and N,N'-dimethyl Methyl formamide (240 mL) was added to the reactor, and the reaction system was heated to 80° C. and reacted for 24 hours under mechanical stirring. Then the temperature of the reaction system was lowered to 40°C, cesium carbonate (50.74g, 155.7mmol), 4-chloromethylstyrene (1.981g, 12.98mmol), benzyl bromide (19.995g, 116.82mmol) and N,N′ were added. -Dimethylformamide (40mL), continue to react at 40°C for 24h. After centrifugal desalting, rotary evaporation and concentration, deionized water precipitation, freeze-drying, the hyperbranched polyester ether type light curing resin HBPEE2 is obtained.

[0033] The infrared absorption spectrum of the hyperbranched polyester ether type photocurable resin HBP...

Embodiment 3

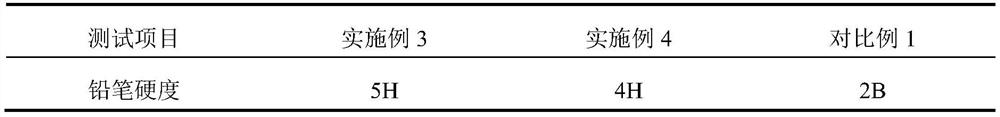

[0035] A photocurable coating containing a hyperbranched polyester ether type photocurable resin, the preparation method of the photocurable coating is:

[0036] Stir 0.5 parts of hyperbranched polyester ether type photocurable resin obtained in Example 1, 70 parts of epoxy soybean oil acrylate and 30 parts of reactive diluent TPGDA into a homogeneous phase at room temperature, and then add 3 parts of photoinitiator 1173 , 0.5 part defoamer, 0.5 part leveling agent, keep stirring for 10 minutes at a speed of 2000r / min in the dark to obtain a photocurable coating containing hyperbranched polyester ether type photocurable resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com