A gallium nitride mis-hemt passivation design and preparation method thereof

A MIS-HEMT, gallium nitride technology, applied in the field of high electron mobility transistor HEMT, can solve the problems of high annealing temperature, increased on-resistance, current collapse, etc., achieves a simple preparation method, improves breakdown voltage, and leakage current. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

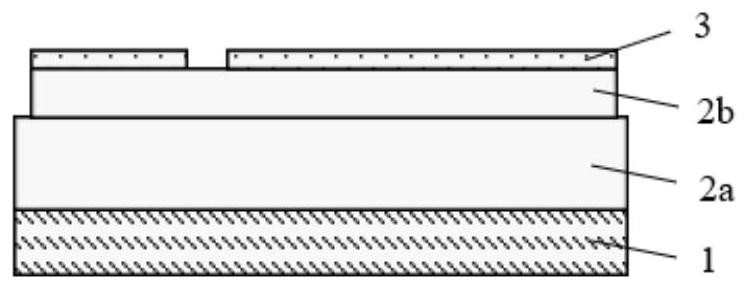

[0041] Generally speaking, the preparation of the present invention has a high dielectric constant dielectric gate dielectric, and the enhanced GaN power device after optimized passivation can be divided into 8 main steps, which are: processing the substrate, etching isolation, etching the gate Groove, sputtering ohmic metal, depositing gate dielectric, evaporating gate metal, sputtering P-type CuO passivation layer, depositing passivation layer.

[0042] This embodiment specifically includes the following steps:

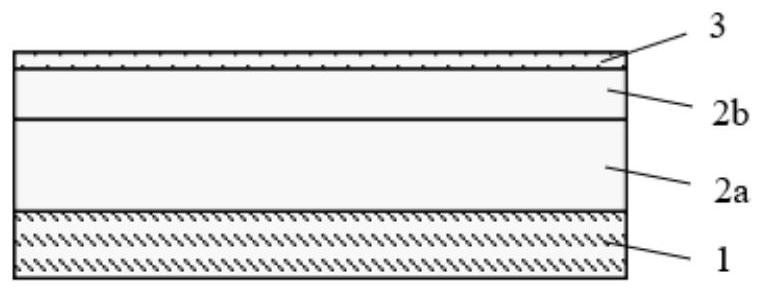

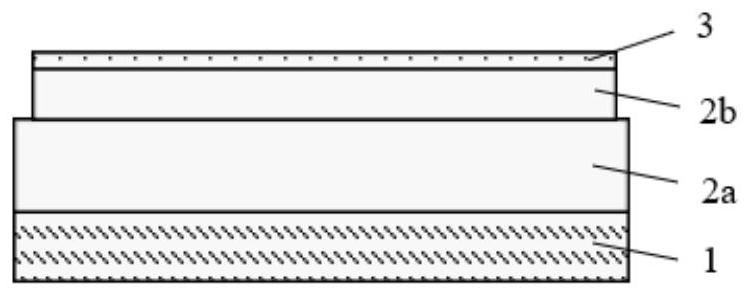

[0043] Step 1, processing the substrate, figure 1 It is a sectional view of a silicon-based GaN substrate, and 1 in the figure is a Si (111) substrate. 2a in the figure is the epitaxial gallium nitride buffer layer. Because the substrate introduces Si and O atoms during the epitaxy process to form vacancies, that is, donor state defects in the buffer layer, electrons are released under the leakage voltage, resulting in large device leakage. At this time, acceptor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com