Neutralizing corrosion inhibitor and application thereof

A corrosion inhibitor and corrosion inhibitor technology, applied in the field of neutralizing corrosion inhibitors, can solve problems such as difficult stability, scaling on the surface of equipment, and failure to effectively inhibit corrosion, so as to achieve low preparation and use costs, avoid under-deposit corrosion, Excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0030] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

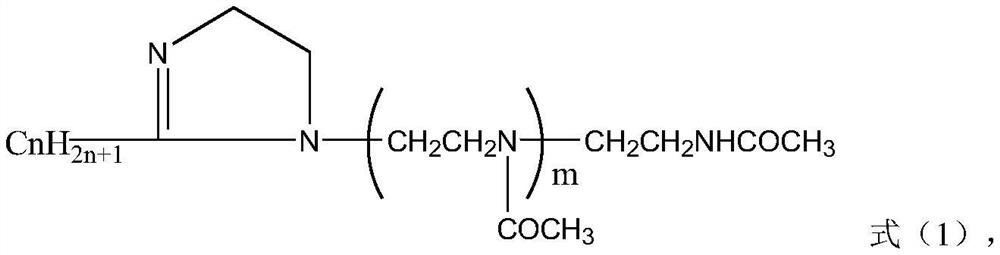

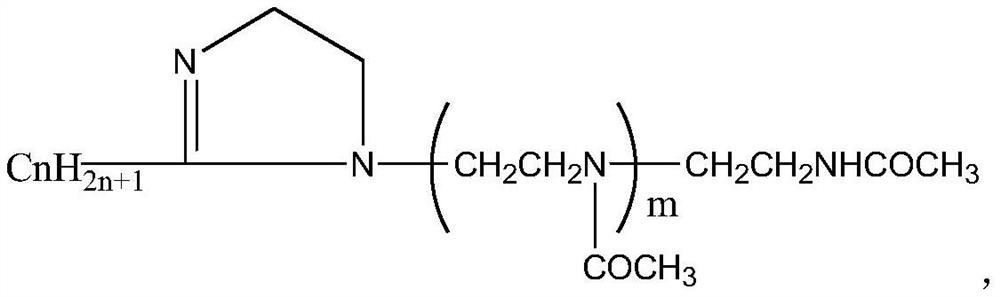

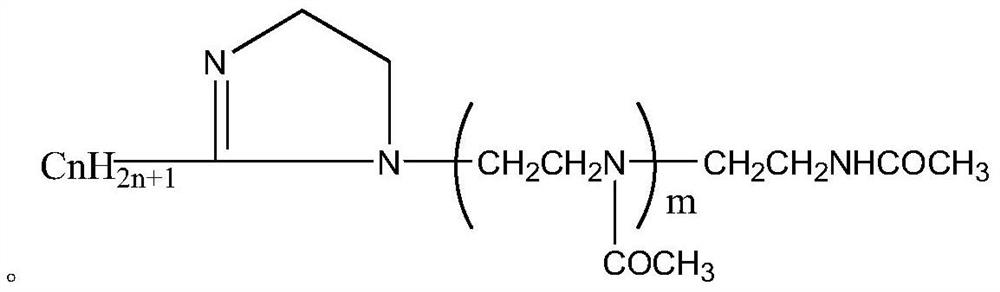

[0031] The synthesis of embodiment 1 imidazoline amide

[0032] Polyethylene polyamine, glacial acetic acid and fatty acid are used as raw materials, and toluene is used as solvent, and the amidation reaction is carried out at a temperature of 110-135°C for 3-5 hours. The resulting product undergoes a ring-closure reaction at a temperature of 200-240°C under normal pressure. 2-5 hours, and steam out toluene, make imidazoline amide, and described imidazoline amide structure is as follows:

[0033]

[0034]

[0035]

Embodiment 2

[0036] Compound and performance test of embodiment 2 water-soluble corrosion inhibitor

[0037] (1) The following raw materials are mixed according to a certain mass ratio, and stirred evenly at room temperature

[0038]

[0039] (2) The corrosion inhibition rate of the composition is tested by coupon weight loss method

[0040] The A3 steel coupons are surface polished, cleaned, soaked, dried, weighed and hung in a container. Add the test solution into the container and set the test time and temperature. After the test is over, take out the coupon, remove the surface grease, remove the corrosion products on the surface of the test piece, wash, dry and weigh it. Calculate the corrosion rate according to the weight loss of the steel piece. The corrosion rate and corrosion inhibition rate are calculated by the following formula:

[0041] Corrosion rate

[0042] m mass loss of test piece, g;

[0043] m o The average value of the mass loss of the test piece pickling blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com