Method for synthesizing methyl p-bromo-methyl benzoate through channelization and reaction device

A technology for methyl bromomethyl bibenzoate and methyl methyl bibenzoate, which is applied in the field of pipeline synthesis of methyl p-bromomethyl bibenzoate and its reaction device, and can solve the problem of inefficient utilization of bromine atoms. Advanced problems, to achieve the effect of strong industrial application value, less by-products, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

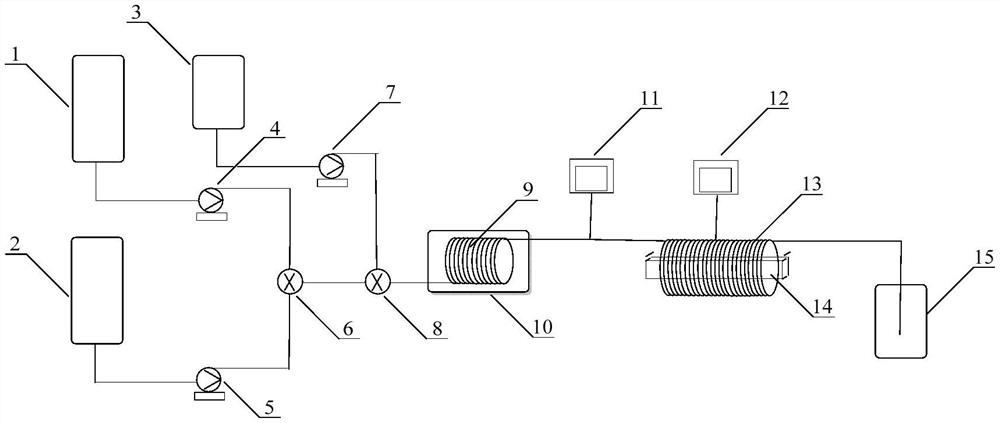

[0050] Reactor such as figure 1 shown. The length of the reactor pipe is 40m, the diameter is 3mm, the pipe material is Teflon, and the light source is a 405nm purple LED lamp.

[0051] First open the semiconductor temperature control box 10 precooling pipelines, the temperature is set at 15°C, add 150mL ice water and 10 grams of sodium carbonate in the receiving tank 15; After dichloromethane is stored in the methyl p-methyl bibenzoate liquid storage tank 1, add a sufficient amount of 40% hydrobromic acid in the hydrobromic acid aqueous solution liquid storage tank 2, add a sufficient amount of in the hydrogen peroxide aqueous solution liquid storage tank 3 30% hydrogen peroxide; after turning on the light source, start each pump to pump the material, adjust the pump speed to make the molar ratio of methyl p-methylbibenzoate:hydrogen bromide:hydrogen peroxide controlled at 1:1.1:1.2, and control the reaction temperature at 35~ 38°C, the reaction time is 15min; after the rea...

Embodiment 2

[0053] The structure of the reaction device is as figure 1 As shown, the length of the reactor pipe is 40m, the diameter is 3mm, the pipe material is Teflon, and the light source is a 475nm blue LED lamp.

[0054] First open the pre-cooling pipeline of the semiconductor temperature control box, the temperature is set at 16°C, add 150mL of ice water and 10 grams of sodium carbonate in the receiving tank 15; After the ethyl ester is stored in the methyl p-methylbibenzoate liquid storage tank 1, add a sufficient amount of 40% hydrobromic acid in the hydrobromic acid aqueous solution liquid storage tank 2, add a sufficient amount of 30% hydrobromic acid in the hydrogen peroxide aqueous solution liquid storage tank 3 % hydrogen peroxide; after turning on the light source, start each pump to pump the material, adjust the pump speed to make methyl p-methyldibenzoate: hydrobromic acid: hydrogen peroxide molar ratio be controlled at 1:1.2:1.4, control the reaction temperature at 36~40 ...

Embodiment 3

[0056] The structure of the reaction device is as figure 1 As shown, the length of the reactor pipe is 40m, the diameter is 3mm, the pipe material is Teflon, and the light source is a 565nm yellow-green LED lamp.

[0057] First open the pre-cooling pipeline of the semiconductor temperature control box, the temperature is set at 16 ° C, add 200 mL of ice water and 10 grams of sodium carbonate in the receiving tank 15; Finally, it is stored in the methyl p-methyl bibenzoate liquid storage tank 1, a sufficient amount of 40% hydrobromic acid is added in the hydrobromic acid aqueous solution liquid storage tank 2, and a sufficient amount of 30% hydrogen peroxide is added in the hydrogen peroxide aqueous solution liquid storage tank 3 After turning on the light source, start each pump to pump the material, adjust the speed of each pump to make methyl p-methylbibenzoate: hydrobromic acid: hydrogen peroxide mol ratio is controlled at 1:1.3:1.5, and the control reaction temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com