Method for removing copper and other impurities in preparing tantalum niobium oxide

An oxide, tantalum and niobium technology, applied in the field of rare metal chemical material extraction, can solve the problems of difficult reduction of impurity F content, failure to meet development requirements, difficulty in copper removal, etc., achieve less reagent consumption and save copper removal reaction time , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

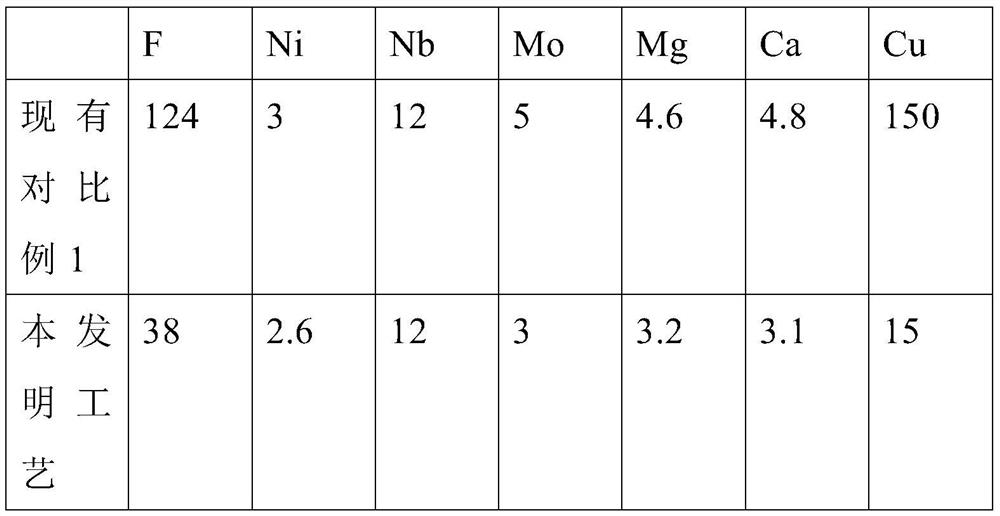

Embodiment 1

[0037] This embodiment discloses a method for removing copper and other impurities in the preparation of tantalum-niobium oxide, which uses the fluoroniobic acid or fluorotantalic acid solution obtained after extraction and separation as a raw material to perform copper removal treatment, including the following steps:

[0038] (1) One-time copper removal treatment, the content of niobium pentoxide in 4000L fluoroniobic acid solution is 130-180g / l, add copper removal agent ammonium sulfide solution 1.8kg to it, and under the condition of constant stirring, stir 2 minutes, perform a copper removal treatment; control the copper content in the fluoroniobic acid or fluorotantalic acid solution to 0.25-0.32g / l; and control the copper removal treatment under acidic conditions; can be added by adding ammonium sulfate solution To adjust the acidity of the solution during the copper removal process, so that copper can be precipitated as much as possible while maintaining its acidic cond...

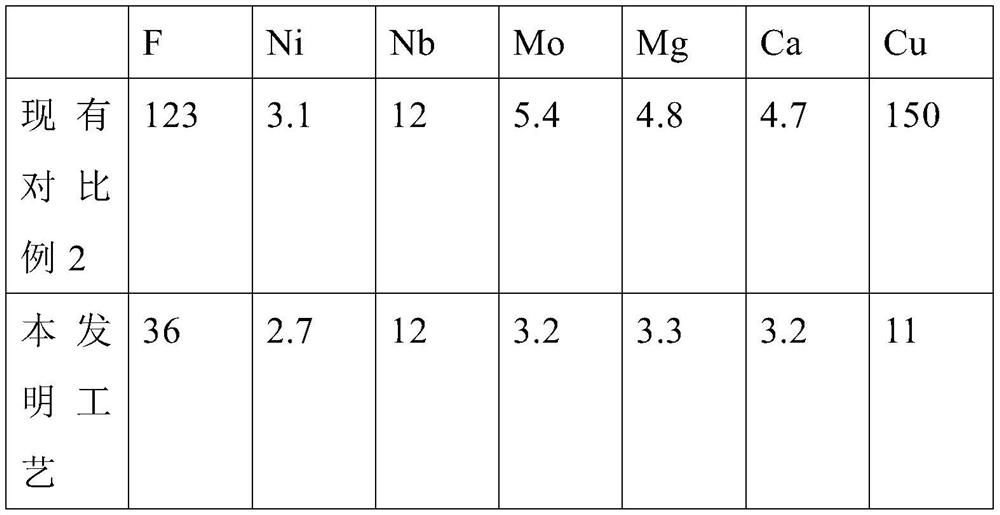

Embodiment 2

[0055] This embodiment discloses a method for removing copper and other impurities in the preparation of tantalum-niobium oxide, which uses the fluoroniobic acid or fluorotantalic acid solution obtained after extraction and separation as a raw material to perform copper removal treatment, including the following steps:

[0056] (1) One time copper removal treatment, in the fluoroniobic acid solution of 4000L, the content of niobium pentoxide is 130-180g / l, to which the copper removal agent solution is added to mix 1.6kg of ammonium sulfide and sodium dithiocarbamate, Control ammonium sulfide and sodium dithiocarbamate to be mixed in a ratio of 92:8 by mass percentage, and stir for 4 minutes under constant stirring to perform a copper removal treatment; control the fluoroniobic acid or fluorotantalic acid The copper content in the solution is 0.28-0.30g / l; and the copper removal treatment is controlled under acidic conditions; the acidity of the solution during the copper remova...

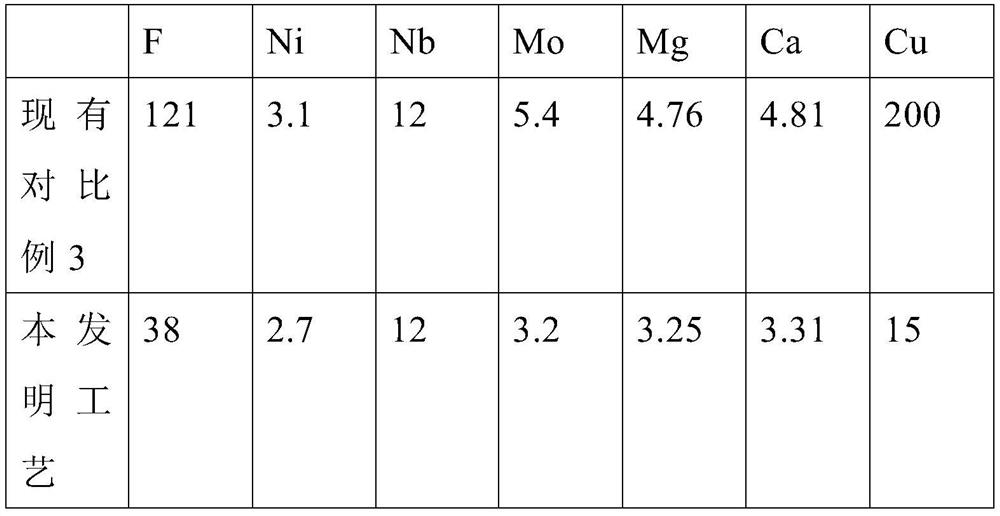

Embodiment 3

[0073] This embodiment discloses a method for removing copper and other impurities in the preparation of tantalum-niobium oxide, which uses the fluoroniobic acid or fluorotantalic acid solution obtained after extraction and separation as a raw material to perform copper removal treatment, including the following steps:

[0074] (1) One-time copper removal treatment, in the 4000L fluoroniobic acid solution, the content of niobium pentoxide is 130-180g / l, and the copper removal agent solution is added to it, which is ammonium sulfide, sodium dithiocarbamate and ammonium sulfate, three Mix 1.6kg of the former, control the ratio of ammonium sulfide, sodium dithiocarbamate and ammonium sulfate to a ratio of 80:5:15 by mass percentage, and stir for 3 minutes under constant stirring to perform a copper removal treatment ; control the copper content in the fluoroniobic acid or fluorotantalic acid solution to be 0.26-0.28g / l; and control the copper removal treatment under acidic conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com