Chinese wolfberry seed oil microcapsule rich in wolfberry color and preparation method of microcapsule

A technology of wolfberry seed oil and wolfberry red pigment, which is applied in the direction of microcapsule preparation, microsphere preparation, and oil-containing food ingredients, etc., can solve the problems of low bioavailability, reduced nutritional value, unhealthy food application, etc., and achieve environmental protection Pollution and resource waste problems, easy storage, and good stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

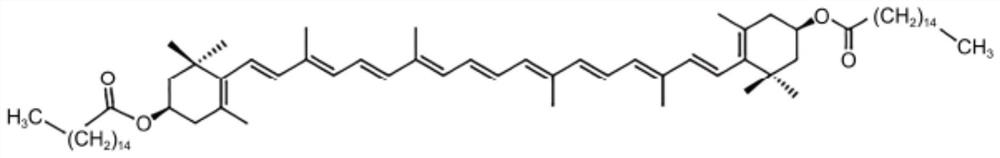

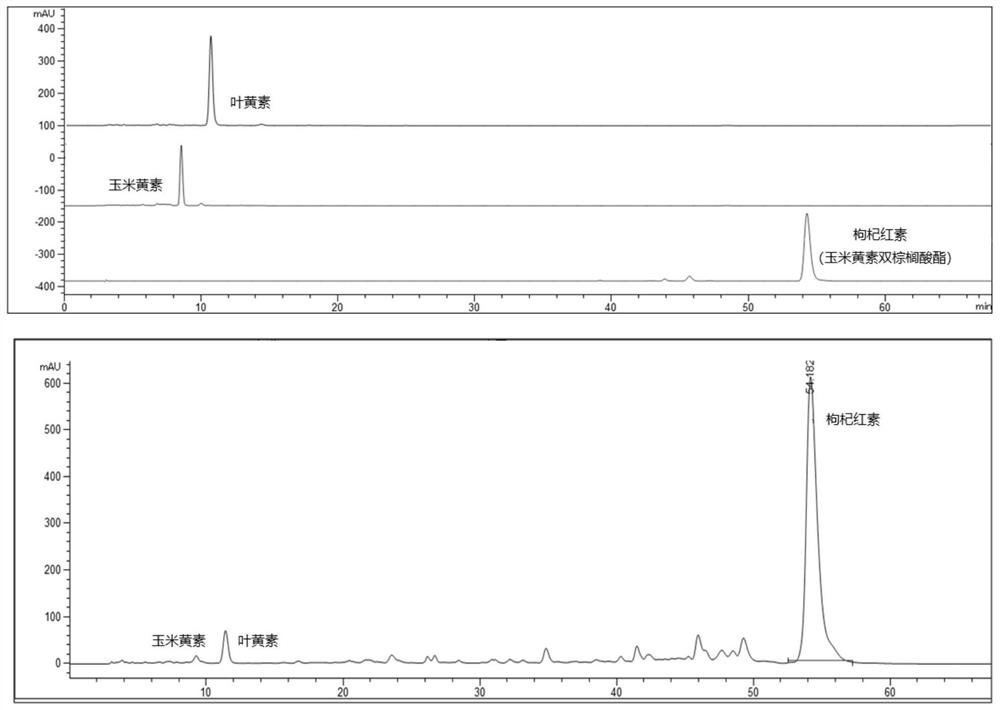

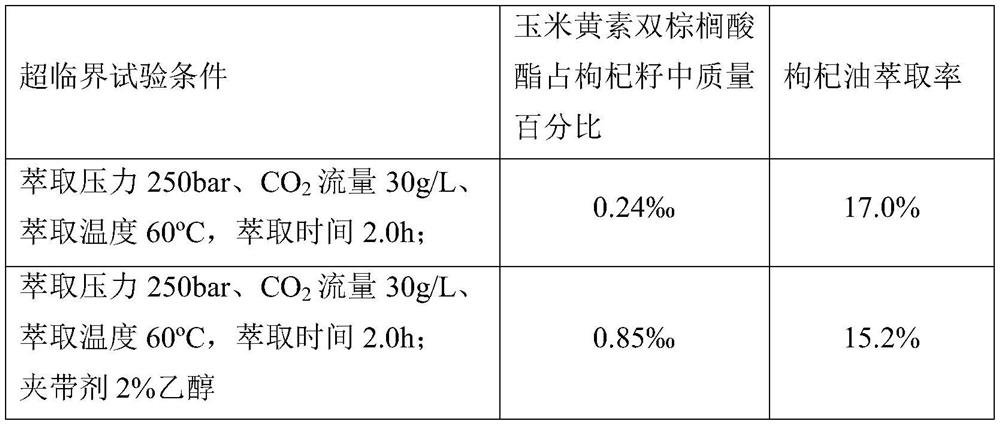

[0025] Example 1: Supercritical CO 2 Determination of extraction conditions

[0026] 1) Grinding and refinement: select the wolfberry seed dregs (cleaned and removed) which are wastes in the processing of wolfberry juice, put them into a pulverizer for crushing for 20-40 minutes, and pass the crushed wolfberry seed powder through a 80-100 mesh sieve.

[0027] 2) Drying and dehydration: spread the wolfberry seed powder sieved in step 1) on a tray, and dry it in an oven at 55°C until it reaches a constant weight.

[0028] 3) Supercritical CO 2 Extraction pressure: fixed CO during the test 2 The flow rate is 40g / L, the extraction temperature is 60°C, and the extraction time is 2.0h. The influence of the extraction pressure on the extraction rate of wolfberry seed pigment is investigated at 150-350bar. The result is that at 200-300bar, the oil yield is about 11.0%. The mass percentage in seeds is about 0.20‰.

[0029] 4) Supercritical CO 2 extract CO 2 Flow rate: During the ...

Embodiment 2

[0036] Embodiment 2: the selection of wolfberry seed oil wall material:

[0037] Table 2 Effect of different wall materials on the embedding rate of Lycium barbarum seed oil

[0038]

[0039] It can be seen from the above table that when the wall material is modified starch (octenyl succinic acid starch ester Hi-CAP100), gum arabic, maltodextrin = 4.5:2.5:1, the embedding rate is significantly higher than other wall material combinations, reaching 92.83%, the obtained medlar seed oil microcapsules are yellow, have no bad smell, have good solubility, and are considered to be the best combination of wall materials.

Embodiment 3

[0040] Embodiment 3: preparation of wolfberry seed oil microcapsules

[0041] The Lycium barbarum seed oil extracted by the supercritical fluid is prepared into powder by microencapsulation technology, and the Lycium barbarum seed oil microcapsule powder is made of 20.0-40.0% core material and 60.0-80.0% wall material, that is, the core material and the The mass ratio of the compound wall material is 1:1.5-1:4, wherein in the compound wall material, the modified starch (octenyl succinic acid starch ester Hi-CAP100), gum arabic, and maltodextrin are 3-1:4 by mass ratio. 6:2-4:1.

[0042] 1) Preparation of wall material solution: mix starch octenyl succinate Hi-CAP100, gum arabic, and maltodextrin with water to make a wall material solution, and starch octenyl succinate Hi-CAP100 in the raw material is 40% , gum arabic 20%, maltodextrin 10%, namely modified starch (octenyl succinic acid starch ester Hi-CAP100), acacia gum, maltodextrin = 4:2:1, form a wall with a solid content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com