Preparation method and application of binder capable of improving rate capability of battery

A rate performance and battery technology, applied in the direction of non-polymer adhesive additives, adhesives, secondary batteries, etc., can solve the problems of reducing the content of active main materials, affecting battery capacity, and large proportion of conductive agents, so as to reduce migration Effects of energy barrier, improvement of overall capacity, and improvement of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0053] (1) Add allyl alcohol as a doping aid to the reaction kettle, and heat it to 45°C for a reaction time of 3 hours, then slowly add diisocyanate (acryl alcohol: diisocyanate = 2.1:1, molar ratio) to carry out Nucleophilic reaction to give reactant A 1 ;

[0054] (2) Mix the binder acrylic acid monomer, water medium and initiator persulfate, heat to 45°C, and then add the reactant A obtained in step (1) 1 , and then slowly feed acetylene gas to obtain acrylic acid polymer B with a smaller molecular weight 1 ;

[0055] Wherein acrylic acid monomer: water medium=1:2.5 (mass ratio), persulfate accounts for 0.06% of the mass of acrylic acid monomer; reactant A 1 Accounting for 6% of the mass of acrylic acid monomer; Acetylene accounts for 20% of the mass of acrylic monomer;

[0056] (3) Reactant B 1 , the substance styrene containing electron-conducting groups, the substance containing ion-conducting groups lithium styrene sulfonate and the initiator persulfate are mixed,...

Embodiment 1B

[0063] Take the finished product PAA1 of the adhesive in Example 1A, use the polyacrylic acid adhesive PAA1 and the negative electrode polyacrylic acid adhesive PAA0 commonly used in the industry for the negative electrode graphite material on the lithium ion battery, and carry out the new material test experiment with matching the lithium element. The test items are as follows.

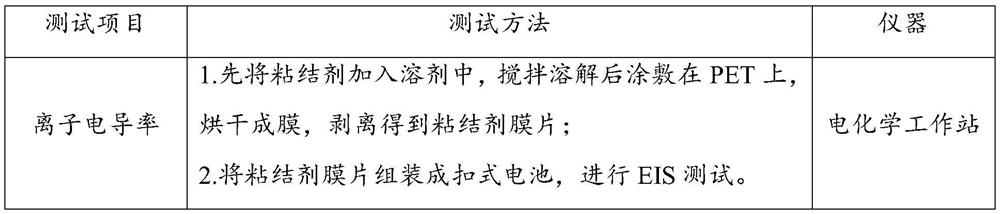

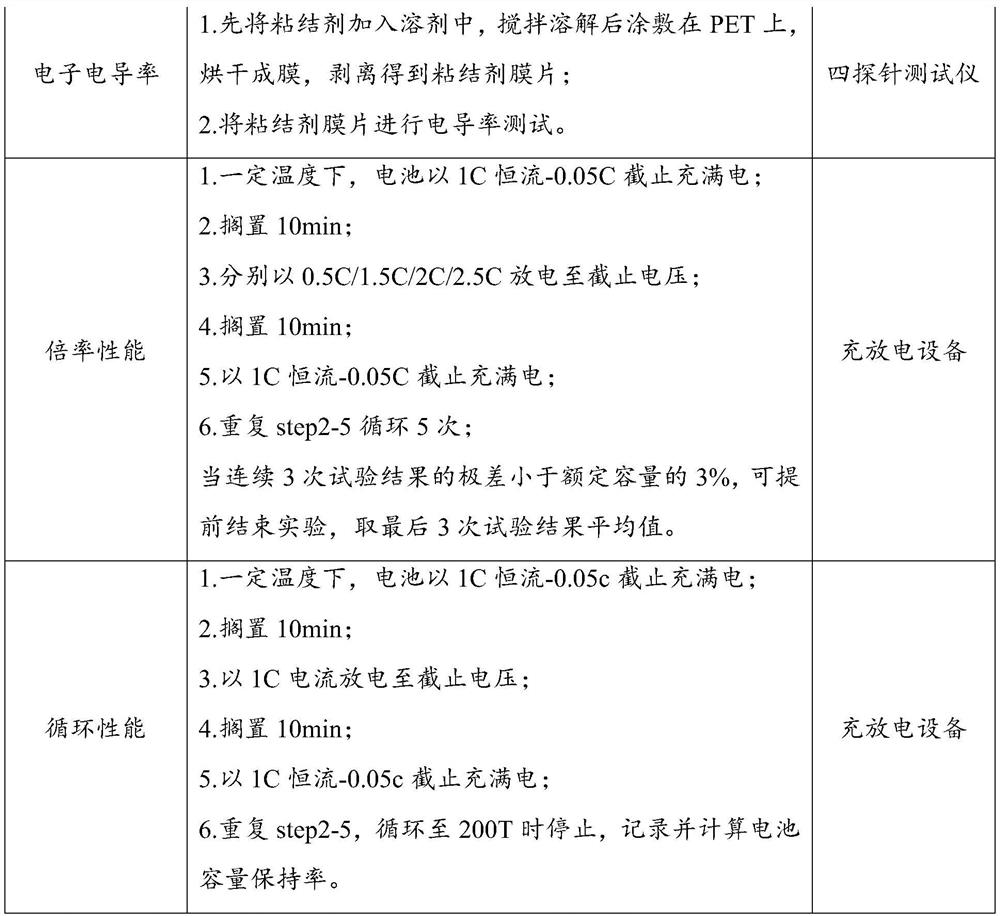

[0064] Table 1 The method and instrument used for testing adhesive products

[0065]

[0066]

[0067] Remarks: The test voltage range of the positive electrode material is 3.0V-4.3V; the test voltage range of the negative electrode material is 5mV-2.0V.

[0068] Ionic conductivity of PAA1 at room temperature 5×10 -4 S / cm, electronic conductivity 8×10 -3 S / cm;

[0069] The capacity retention rates of the battery (using PAA1) at 25°C at 1.5C, 2C, and 2.5C / 0.5C are 89.2%, 85.2%, and 81.6%, respectively. 25°C 1C / 1C cycle 200T battery capacity retention rate is 92.5%.

[0070] The capacity ret...

Embodiment 2

[0073] (1) Mix the binder vinylidene fluoride monomer, water medium and initiator AIBN (azobisisobutyronitrile), heat to 45°C, then add the doping group substance pyrrole monomer and crosslinking aid acrylic acid, and then slowly feed acetylene gas to obtain acrylic acid polymer B with a smaller molecular weight 2 ;

[0074] Vinylidene fluoride monomer: water medium = 1:4, AIBN accounts for 0.08% of the mass of vinylidene fluoride monomer; pyrrole monomer accounts for 5% of the mass of vinylidene fluoride monomer; acrylic acid accounts for 0.2% of the mass of vinylidene fluoride monomer ; Acetylene accounts for 20% of the mass of vinylidene fluoride monomer;

[0075] (2) Reactant B 2 , material aniline monomer containing electron conducting group, material p-styrenesulfonate lithium and initiator AIBN containing ion conducting group are mixed, and heated to 90°C to obtain grafted improved vinylidene fluoride polymer C1 2 (Molecular weight is about 30,000);

[0076] where A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com