Heavy rare earth doped ZnO columnar crystal preferred orientation piezoelectric film material and preparation method thereof

A technology of preferential orientation and piezoelectric thin film, which is applied in the material selection of piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials, etc., it is easy to achieve process parameters, Stable structure and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

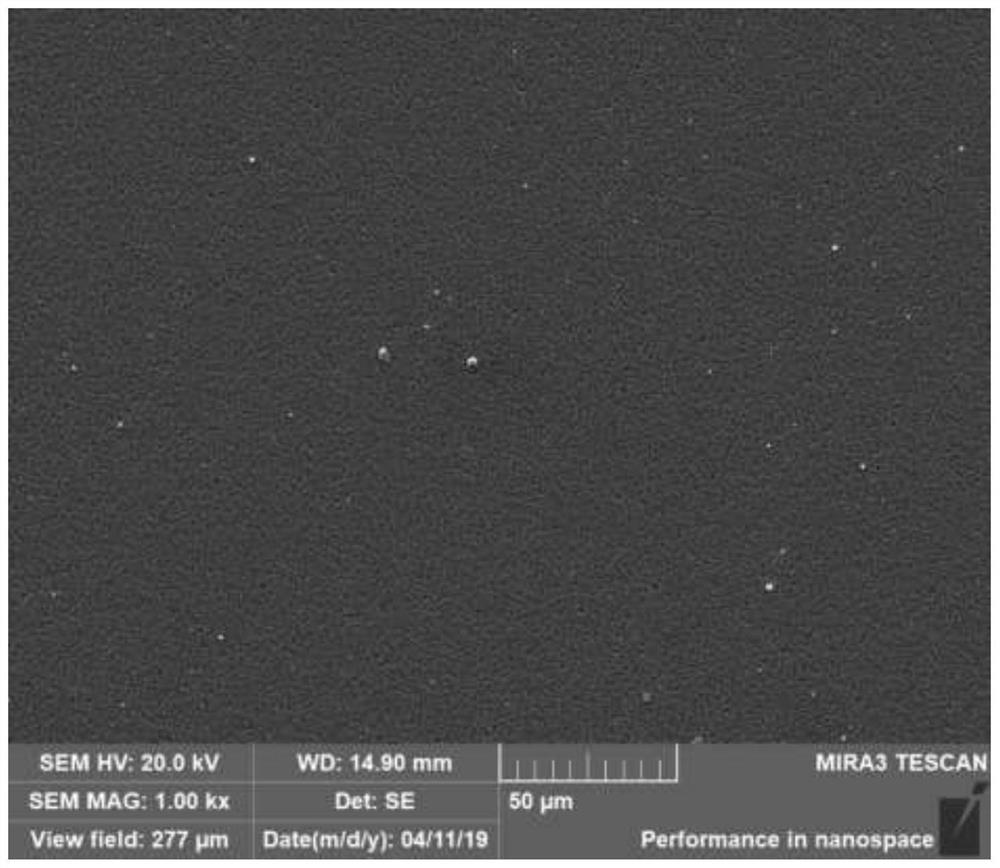

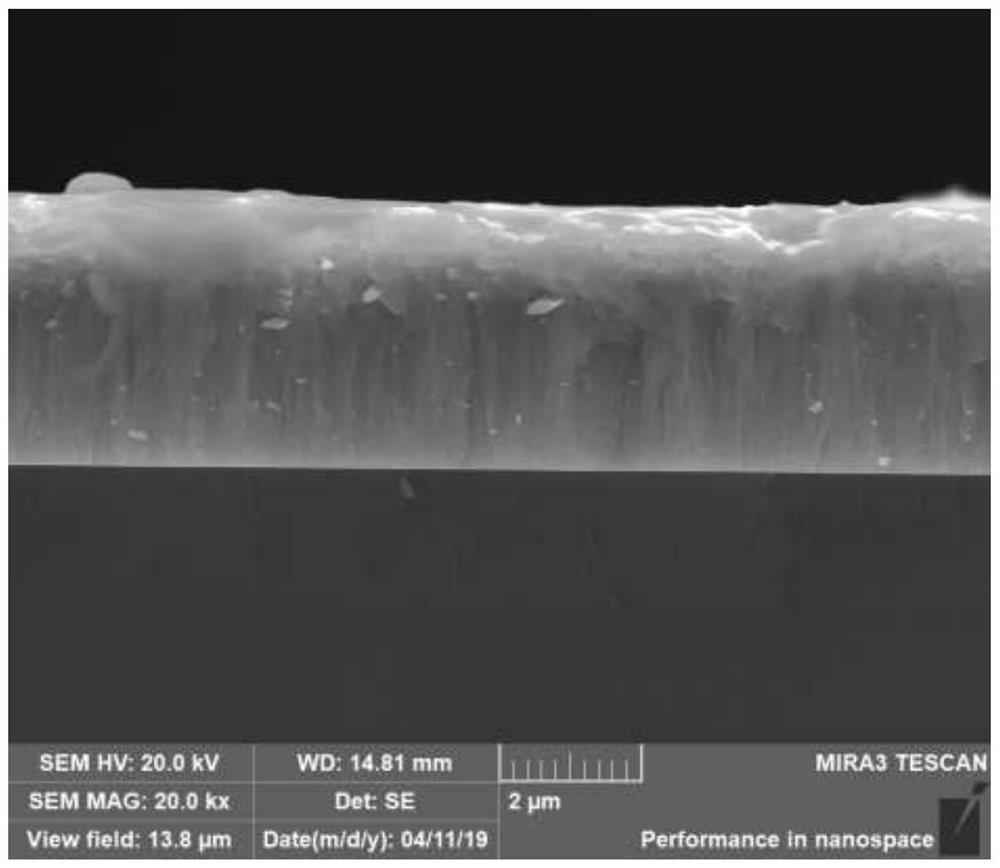

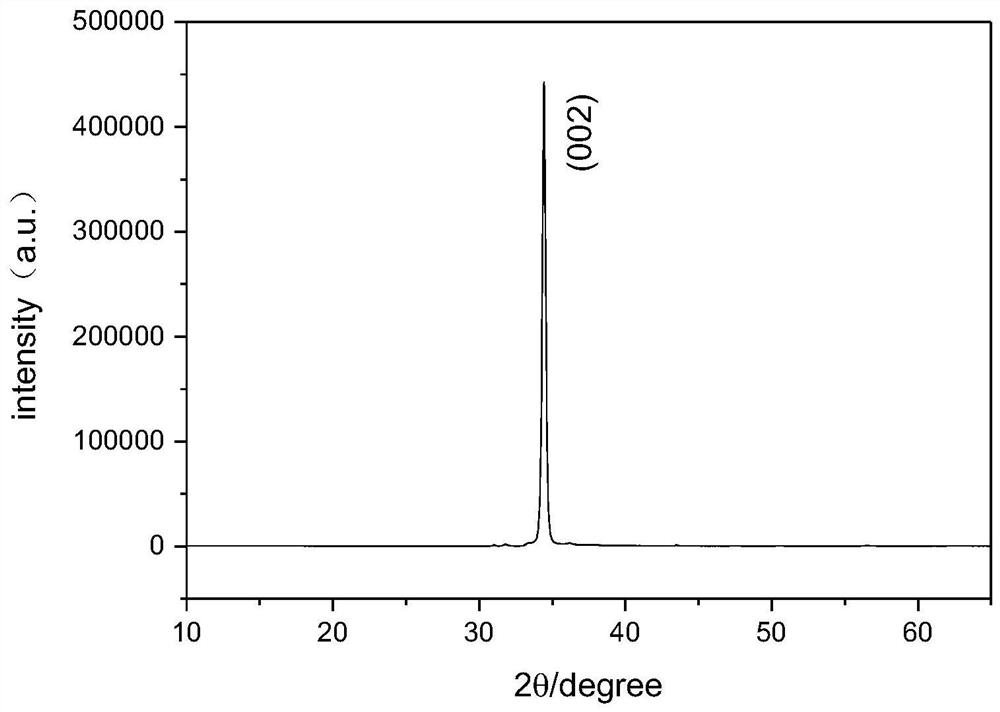

[0035] A heavy rare earth-doped ZnO columnar crystal preferred orientation piezoelectric thin film material, the preparation method of which comprises the following steps:

[0036] 1) Preparation of heavy rare earth doped zinc target material, mixing heavy rare earth and zinc powder to prepare mixed powder, using hot isostatic pressing technology (500°C, 30MPa) to press into heavy rare earth doped zinc target material; The doping ratio is 5 at.%, and the doping conditions of each specific rare earth element are: yttrium 1 at.%, scandium 2 at.%, erbium 2 at.%;

[0037] 2) The Si substrate is ultrasonically cleaned with acetone and deionized water in sequence, and then dried in a nitrogen environment and placed in a vacuum chamber. The substrate is glow-cleaned in an inert gas (nitrogen) environment with a target distance of 25 cm , the glow cleaning bias voltage is -500V, and the air pressure is 2.5Pa;

[0038] 3) After the glow cleaning is finished, in the argon and oxygen at...

Embodiment 2

[0041] A heavy rare earth-doped ZnO columnar crystal preferred orientation piezoelectric thin film material, the preparation method of which comprises the following steps:

[0042]1) Preparation of heavy rare earth doped zinc target material, mixing heavy rare earth and zinc powder to prepare mixed powder, using hot isostatic pressing technology (500°C, 30MPa) to press into heavy rare earth doped zinc target material; The doping ratio is 5 at.%, and the doping conditions of each specific rare earth element are: yttrium 3 at.%, scandium 1 at.%, erbium 1 at.%;

[0043] 2) The Si substrate was ultrasonically cleaned with acetone and deionized water in sequence, and then dried in a nitrogen environment and placed in a vacuum chamber. The substrate was glow-cleaned with a target-base distance of 30 cm and an inert gas environment. The cleaning bias voltage is -600V, and the air pressure is 2.4Pa;

[0044] 3) After glow cleaning, in argon and oxygen atmosphere, the temperature is c...

Embodiment 3

[0047] A heavy rare earth-doped ZnO columnar crystal preferred orientation piezoelectric thin film material, the preparation method of which comprises the following steps:

[0048] 1) Preparation of heavy rare earth doped zinc target material, mixing heavy rare earth and zinc powder to prepare mixed powder, using hot isostatic pressing technology (500°C, 30MPa) to press into heavy rare earth doped zinc target material; The doping ratio is 2.5 at.%, and the doping conditions of each specific rare earth element are: 0.5% yttrium, 1% scandium, and 1% erbium;

[0049] 2) The quartz glass is ultrasonically cleaned with acetone and deionized water in sequence, and then dried in a nitrogen environment and placed in a vacuum chamber. Under the target-base distance of 30cm and an argon environment, the substrate is glow-cleaned, glow-cleaned The bias voltage is -700V, and the air pressure is 2.3Pa;

[0050] 3) After the glow cleaning, in the argon and oxygen atmosphere, the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com