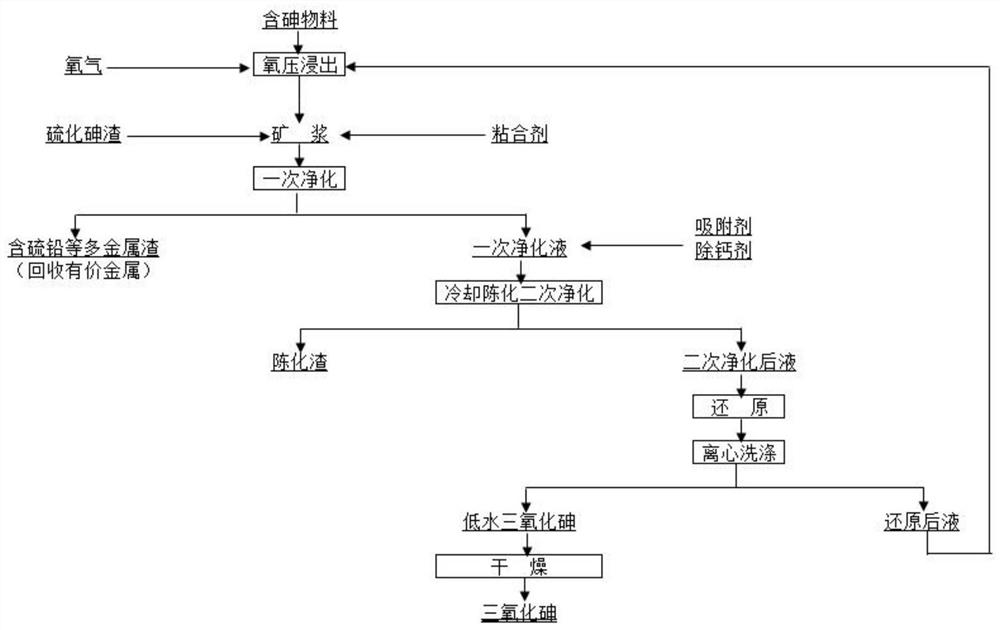

Process for producing qualified arsenic oxide from arsenic-containing material by full-wet method

An arsenic oxide, all wet process technology, applied in the direction of arsenic oxide/arsenic hydroxide/oxyacid arsenic, arsenic compound, process efficiency improvement, etc. Achieve the effect of enhancing product value, compact process, friendly and safe labor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Take 200g of arsenic-containing material (the amount of soot is about 120g), add 1000ml of reduced liquid, oxygen pressure leaching, oxygen pressure temperature 120 ° C, oxygen partial pressure 0.5Mpa, react for 3h, after the leaching is completed, take out the pulp and add 22 grams Arsenic sulfide slag and binder mixture (20 grams of arsenic sulfide slag, 2 grams of limestone), when the temperature drops to 90 ° C, the rotation speed is 131r / min and stirred for 30min, and 1000ml of primary purification solution is obtained by filtration. The composition and content are: As 5+ 120g / L, As 3+ 22g / L, H 2 SO 4 35g / L, SiO 2 0.03%, Ca 2+ 0.04%. Add 3 grams of activated carbon and 1 gram of NaF to the first purification solution, the temperature is about 60 ° C, stir for 30 minutes, cool to room temperature and let stand for 36 hours, filter with precision filter paper to obtain the second purified liquid: As 5+ 120g / L, As 3+ 22g / L, H 2 SO 4 35g / L, SiO 2...

Embodiment 2

[0036] Example 2: Take 100g of arsenic-containing material (the amount of soot is about 60g), add 500ml of reduced liquid, leaching with oxygen pressure, 110 ° C, oxygen partial pressure 0.3Mpa, react for 3h, after leaching is completed, filter to obtain arsenic-containing leaching solution and leaching residue , the leaching solution was added with arsenic sulfide slag to reduce Wujia arsenic to trivalent arsenic at 95 °C, and 45 g of arsenic trioxide crystals were obtained by cooling and crystallization. 2 O 3 The content is 93.8%, and the output arsenic oxide cannot reach qualified analytical purity.

Embodiment 3

[0037] Example 3: Take 1000kg of arsenic-containing material (the amount of soot is about 60kg), add 5m 3 After reduction, oxygen pressure leaching, oxygen pressure temperature 130°C, oxygen partial pressure 0.45Mpa, reaction for 100min, after leaching is completed, take out the pulp and add 120kg (100kg arsenic sulfide slag, 20kg limestone), and stir until the temperature drops to about 90°C 30min, filtered to obtain 5.1m of primary purification solution 3 , the composition and content are: As 5+ 122g / L, As 3+ 21g / L, H 2 SO 4 36g / L, SiO 2 0.04%, Ca 2+ 0.05%. Add 30kg lignite and 10kg NaF to the primary purification solution, stir at 60°C for 30min, cool to room temperature and let stand for 36h, add 20-mesh filter paper and filter to obtain the second purified solution: As 5+ 126g / L, As 3+ 22g / L, H 2 SO 4 36g / L, SiO 2 0.008%, Ca 2+ 0.01%. After the second cleaning, the sulfur dioxide gas was slowly introduced into the liquid, mechanically stirred, the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com