A kind of environment-responsive Paecilomyces lilacinus microbeads and preparation method thereof

A technology of Paecilomyces lilacinus and environment response, which is applied in the field of environment-responsive Paecilomyces lilacinus microbeads and the preparation thereof, can solve the problems of inability to improve the growth environment of crops, pathogenic microorganisms, etc., so as to avoid early recovery and enlargement Gel strength, the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

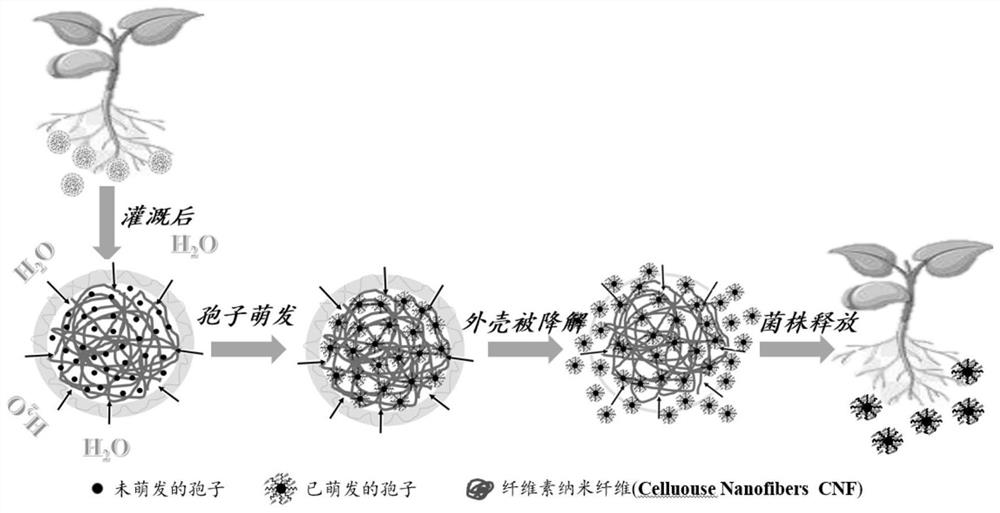

[0031] Embodiment 1: A kind of water-responsive Paecilomyces lilacinus microbeads

[0032] (1) Preparation of core material solution: Add 250g of Paecilomyces lilacinus spore powder, 600g of corn oil, and 20g of sodium citrate into a beaker, stir at room temperature for 30min, mix well, then add surfactant dodecylphenol polyoxyethylene 10g of a mixture of ether, polyoxyethylene lauryl ether and sodium lauryl sulfate (mass ratio 2:2:1), after forming an emulsifiable concentrate, add 15g of glucose, 10g of peptone, and 40g of cellulose nanofibers in sequence, and stir at room temperature for 30min. Obtain the core material solution.

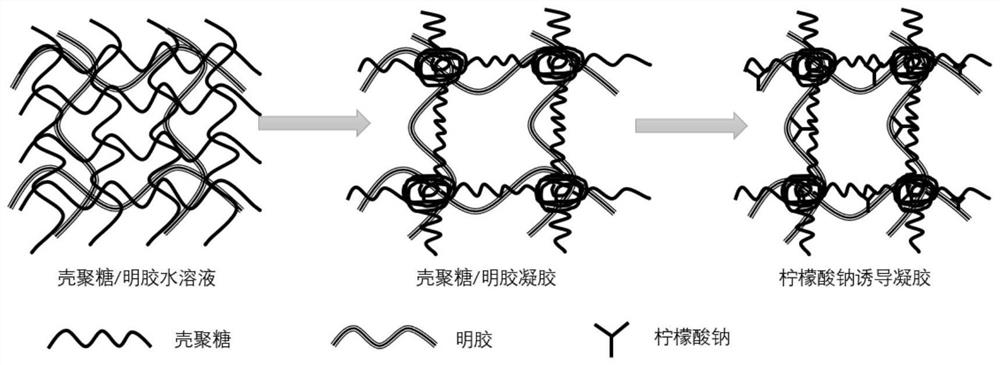

[0033] (2) Preparation of wall material solution: Add 1.5g of chitosan, 10g of gelatin, 4g of polyvinyl alcohol (the degree of polymerization of polyvinyl alcohol is 500-600), and 8g of glycerin into 80mL of distilled water, heat to 95-100°C, and mix Evenly, keep warm at 95-96°C to get wall material solution.

[0034] (3) core material and wall m...

Embodiment 2

[0070] Embodiment 2 A kind of water response type Paecilomyces lilacinus microbeads

[0071] (1) Preparation of core material solution: Add 200g of Paecilomyces lilacinus spore powder, 400g of soybean oil, and 25g of sodium citrate into a beaker, stir at room temperature for 30min, and mix well, then add the surfactant octylphenol polyoxyethylene ether, After the mixture of fatty alcohol sodium sulfate 12g (mass ratio 2:1) forms an emulsifiable concentrate, add 10g of glucose, 5g of peptone, and 30g of cellulose nanofibers in sequence, and stir at room temperature for 30min to obtain a core material solution.

[0072] (2) Preparation of wall material solution: Add 1.5g of chitosan, 8g of gelatin, 3g of polyvinyl alcohol (the degree of polymerization of polyvinyl alcohol is 500-600), 6g of glycerin into 60mL distilled water, heat to 95-100°C, mix Evenly, keep warm at 95-96°C to get wall material solution.

[0073] (3) core material and wall material solution that step (1) (2) ...

Embodiment 3

[0074] Embodiment 3 A kind of water-responsive Paecilomyces lilacinus microbeads

[0075] (1) Prepare the core material solution: add 300g of Paecilomyces lilacinus spore powder, 500g of rapeseed oil, and 30g of sodium citrate into a beaker, stir at room temperature for 30min, mix well, then add surfactant castor oil polyoxyethylene ether, A mixture of styrylphenol polyoxyethylene ether and calcium dodecylbenzenesulfonate 12g (mass ratio 3:1:1), after forming an emulsifiable concentrate, add 12g of glucose, 8g of peptone, and 50g of cellulose nanofibers in sequence, and stir at room temperature 30min, to obtain the core material solution.

[0076] (2) Preparation of wall material solution: Add 2.0 g of chitosan, 10 g of gelatin, 5 g of polyvinyl alcohol (the degree of polymerization of polyvinyl alcohol is 500-600), and 10 g of glycerin into 100 mL of distilled water, heat to 95-100 ° C, and mix Evenly, keep warm at 95-96°C to get wall material solution.

[0077] (3) core ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com