A kind of anti-mud type polycarboxylate water reducer and preparation method thereof

A polycarboxylate-based, mud-resistant technology, applied in the field of polycarboxylate water-reducing agents for concrete, can solve the problems of reduced concrete water-reducing rate and slump-retaining performance, increased PCE water-reducing agent content, and prolonged concrete setting time and other problems, to achieve the effect of reducing surface adsorption, avoiding adverse effects, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

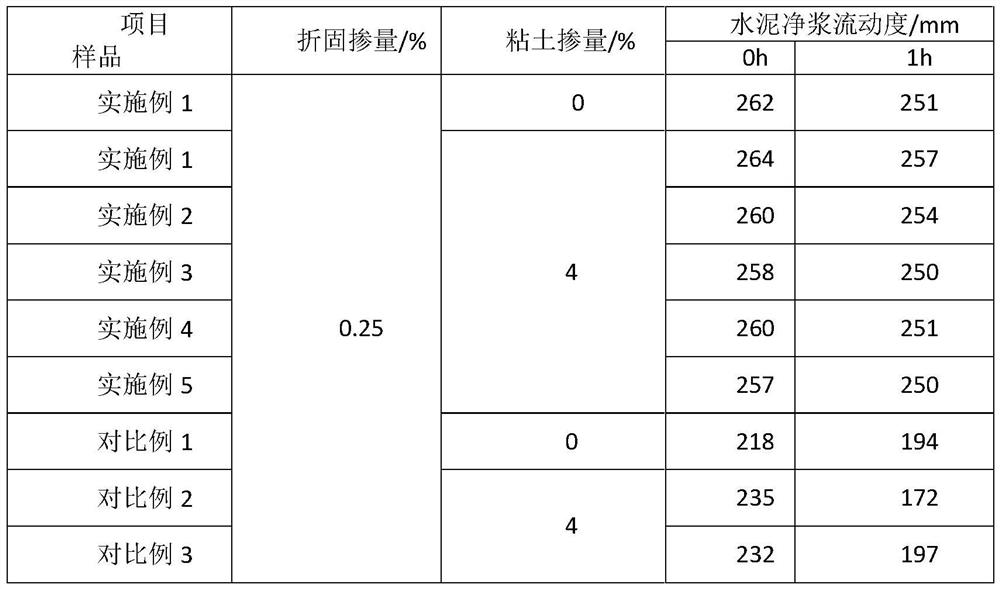

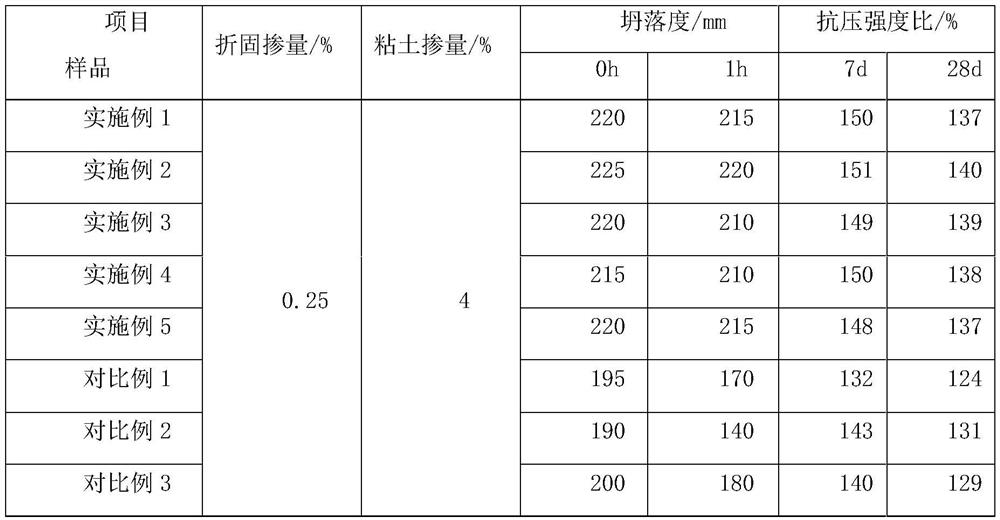

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned anti-mud type polycarboxylate water-reducing agent comprises the following steps:

[0035] Step 1, dissolving the multi-arm polymer precursor in part of dimethyl sulfoxide to form a bottom liquid;

[0036] Step 2, dissolving methacrylic polyethylene glycol ether, unsaturated acid monomer, acryloyloxyethyltrimethylammonium chloride and chain transfer agent in part of dimethyl sulfoxide to form material A;

[0037] Step 3, the initiator is dissolved in part dimethyl sulfoxide to form B material;

[0038] Step 4, heat the bottom material to 62°-68°, start to drip A and B materials at a constant speed, and keep the temperature at 62°-68° for 3.0h after the dripping is completed;

[0039] Step 5: After the heat preservation is completed, the solution is cooled to room temperature, the impurities are removed by dialysis, and then the solvent is removed to obtain an anti-sludge type polycarboxylate water-reducing agent.

[0040] ...

Embodiment 1

[0045]Dissolve polyvinyl alcohol in dimethyl sulfoxide at 50 °C to form a PVA solution with a concentration of 2%, add 2 times the mass of polyvinyl alcohol with acryloyl chloride and an appropriate amount of concentrated sulfuric acid into the PVA solution, and reflux at 50 °C for 3 hours. Then stop the reaction. The solution is poured into a beaker filled with water, precipitated, filtered, washed, and dried in a vacuum drying oven to obtain a multi-arm polymer precursor. Dissolve 6.5 parts of the multi-arm polymer precursor in part of dimethyl sulfoxide to form a bottom liquid, 28 parts of methacrylic polyglycol ether, 22 parts of acrylic acid, 13 parts of acryloyloxyethyl trimethyl chloride Ammonium, 1.2 parts of 2,4-diphenyl-4-methyl-1-pentene were dissolved in part of dimethyl sulfoxide to form feed A, and 0.9 parts of dibenzoyl peroxide was dissolved in part of dimethyl sulfoxide Form B material in the sulfone, heat the bottom material to 65±3°, start adding A and B ma...

Embodiment 2

[0047] Dissolve polyvinyl alcohol in dimethyl sulfoxide at 50 °C to form a PVA solution with a concentration of 3%, add 2 times the mass of polyvinyl alcohol with acryloyl chloride and an appropriate amount of concentrated sulfuric acid into the PVA solution, and reflux at 50 °C for 3 hours. Then stop the reaction. The solution is poured into a beaker filled with water, precipitated, filtered, washed, and dried in a vacuum drying oven to obtain a multi-arm polymer precursor. Dissolve 8 parts of the multi-arm polymer precursor in part of dimethyl sulfoxide to form a bottom liquid, mix 30 parts of methacrylic polyglycol ether, 20 parts of methacrylic acid, 10 parts of acryloyloxyethyl trimeth Ammonium chloride and 0.8 parts of isooctyl 3-mercaptopropionate are dissolved in part of dimethyl sulfoxide to form A material, 1.5 parts of dibenzoyl peroxide are dissolved in part of dimethyl sulfoxide to form B material, and The bottom material is heated up to 65±3°, and the A and B ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com