Phase-change temperature control material and preparation method thereof

A technology of phase change temperature control and phase change metal, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem of undeveloped phase change temperature control materials, organic phase change materials with small thermal conductivity, heat absorption or release Slow and other problems, to achieve the effect of large latent heat of phase change, increased interaction, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

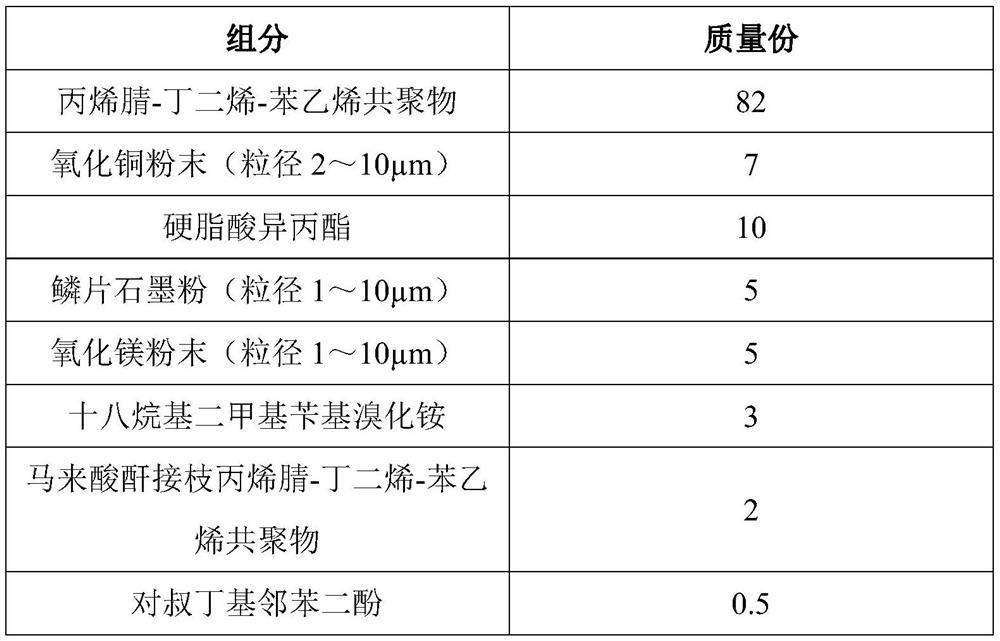

[0051] A phase change temperature control material, the composition of which is shown in the following table:

[0052] Table 1 Composition table of a phase change temperature control material

[0053] components parts by mass polycarbonate resin 75 Zirconia powder (particle size 2~10μm) 2 tris hydroxymethyl amino methane 8 Boron nitride powder (particle size 1~10μm) 8 Benzyltriethylammonium Chloride 2 ascorbic acid 1

[0054] The preparation method of the above-mentioned phase change temperature control material comprises the following steps: adding polycarbonate resin, zirconium dioxide powder, trimethylolaminomethane, boron nitride powder, benzyltriethylammonium chloride and ascorbic acid into the mixer, adjusting The speed of the mixer is 550r / min, stirring for 15min, and then transferred to the twin-screw extruder, the processing temperature is controlled at 215-230°C, the screw speed is 45-70r / min, extruded and granulated...

Embodiment 2

[0056] A phase change temperature control material, the composition of which is shown in the following table:

[0057] Table 2 Composition table of a phase change temperature control material

[0058]

[0059] The preparation method of the above-mentioned phase change temperature control material comprises the following steps: acrylonitrile-butadiene-styrene copolymer, copper oxide powder, isopropyl stearate, flake graphite powder, magnesium oxide powder, octadecyl diacetate Add methyl benzyl ammonium bromide, maleic anhydride grafted acrylonitrile-butadiene-styrene copolymer and p-tert-butylcatechol into the mixer, adjust the speed of the mixer to 600r / min, stir for 10min, and then transfer to double The screw extruder controls the processing temperature at 165-185°C and the screw speed at 55-80r / min, extrudes and granulates, and obtains the phase-change temperature-controlling material.

Embodiment 3

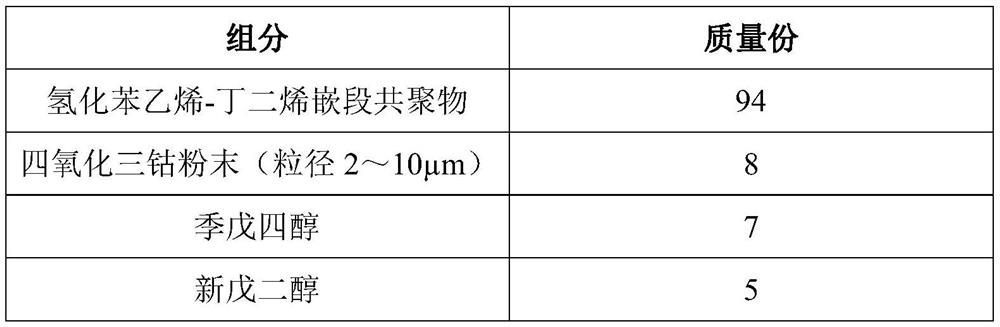

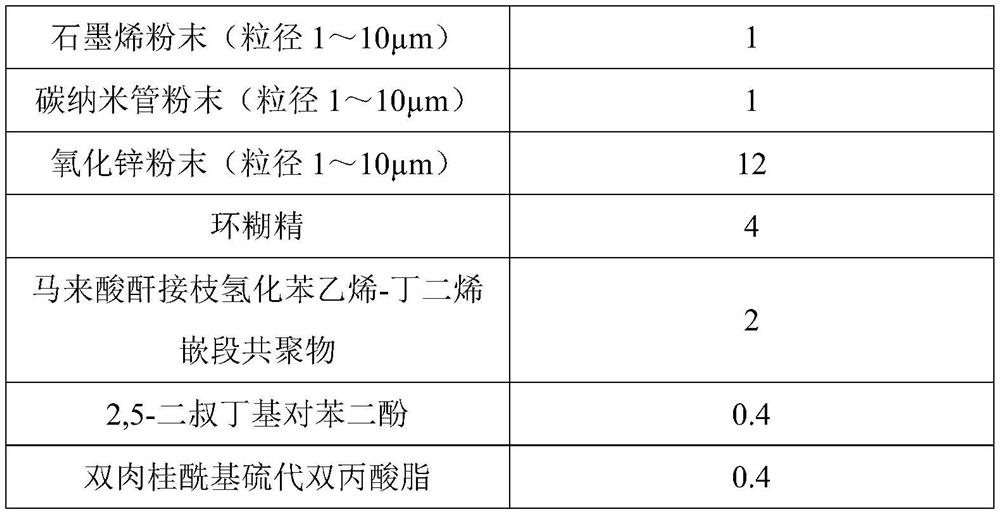

[0061] A phase change temperature control material, the composition of which is shown in the following table:

[0062] Table 3 Composition table of a phase change temperature control material

[0063] components parts by mass polyamide resin 90 Vanadium dioxide powder (particle size 2~10μm) 5 paraffin 10 Thermally conductive carbon powder (particle size 1~10μm) 7 Boron nitride powder (particle size 1~10μm) 5 Sodium Glycocholate 4 citric acid 0.3 Antioxidant 264 0.5

[0064] The preparation method of the above-mentioned phase change temperature control material comprises the following steps: adding polyamide resin, vanadium dioxide powder, paraffin wax, thermal conductive carbon powder, boron nitride powder, sodium glycocholate, citric acid and antioxidant 264 into the mixer, adjusting The speed of the mixer is 800r / min, stirring for 20min, and then transferred to the twin-screw extruder, the processing temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com