Copper-indium-gallium-selenium thin-film solar cell module and preparation method thereof

A solar cell, copper indium gallium selenide technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of residue falling into the trench, affecting photoelectric conversion efficiency, and high equipment cost, so as to reduce the possibility of leakage current performance, improve photoelectric conversion efficiency, and improve process compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

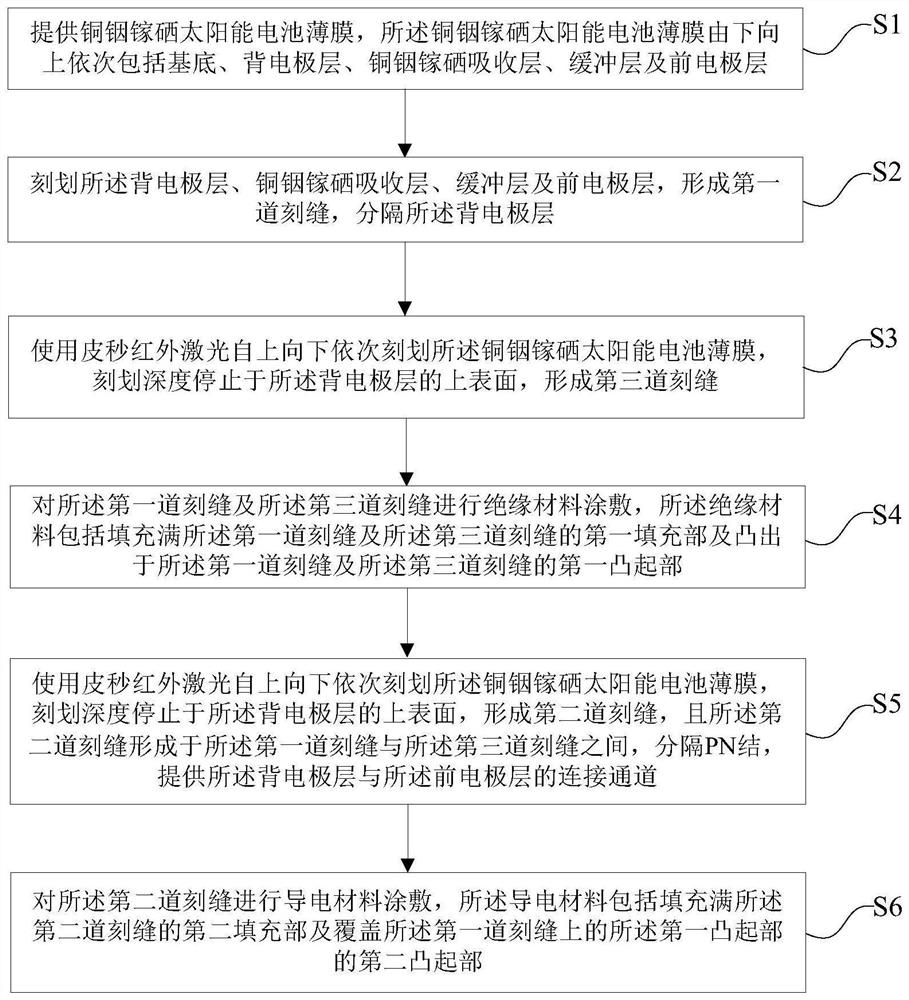

[0056]This embodiment provides a method for preparing a copper indium gallium selenide solar cell module, which uses picosecond infrared lasers to realize the P2 / P3 (second slit and third slit) process scribing of the copper indium gallium selenide module. The picosecond infrared laser pulse has a very high energy intensity and a very high power density, which is enough to strip the outer layer of the material and achieve the effect of removing the "electronic state" of the material. It has high efficiency, no thermal effect and a non-contact process, so there is no edge chipping. There are no cracks and residual stress. The scribing quality fully meets the process requirements of CIGS module production for CIGS thin-film solar scribing, greatly improving the scribing quality. In addition, the line width of picosecond infrared laser scribing is very small, which is effective Reduce the dead zone area of the battery module and improve the photoelectric conversion efficiency of the ...

Embodiment 2

[0079]This embodiment provides a copper indium gallium selenide thin-film solar cell module. The copper indium gallium selenide thin-film solar cell module can be prepared by the preparation method of the first embodiment, but is not limited to the preparation method described in the first embodiment, as long as it can be formed This copper indium gallium selenium thin film solar cell module is sufficient. The beneficial effects that can be achieved by the copper indium gallium selenide thin film solar cell module can be found in the first embodiment, which will not be described in detail below.

[0080]Such asFigure 2 to Figure 7As shown, the copper indium gallium selenium thin film solar cell module includes:

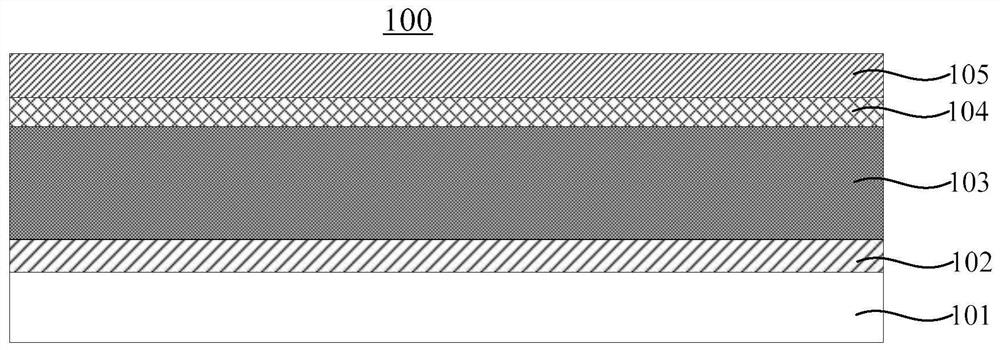

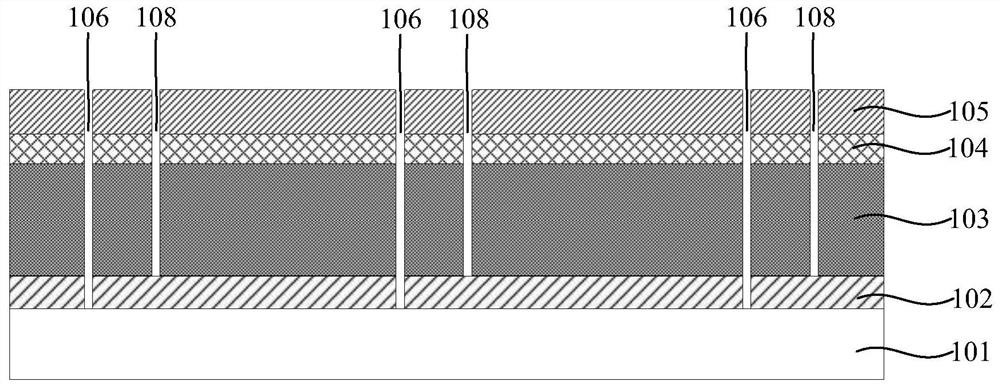

[0081]At least two battery blocks 115 formed on the copper indium gallium selenide solar cell film 100. The copper indium gallium selenide solar cell film 100 includes a substrate 101, a back electrode layer 102, a copper indium gallium selenide absorption layer 103, The buffer l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com