Preparation process for producing organic fertilizer from plant straws and traditional Chinese medicine residues

A plant straw, organic fertilizer technology, applied in the preparation of organic fertilizers, organic fertilizer equipment, organic fertilizers, etc., can solve the problem that it can only be applied in landscaping, flower lawns, such as other field crops and economic crops. Organic fertilizers have problems such as odor, toxic and harmful substances, and the quality of organic fertilizers cannot be achieved, which can shorten the fertilizer production cycle, inhibit the effects of pests and diseases, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

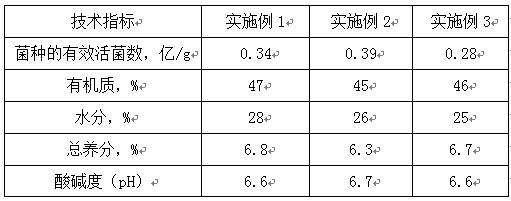

Embodiment 1

[0034] (1) Prepare plant straw, traditional Chinese medicine residue, organic material decomposing agent, and biological fermentation bacteria in a weight ratio of 75:24.8:0.1:0.1 for use;

[0035] The plant straws are rice straws, potato straws, corn straws and rapeseed straws in a weight ratio of 1:2:1:1.5;

[0036] The traditional Chinese medicine dregs include Guanzhong, Scrophulariaceae, Baiwei, Shegan, Licorice, Red Teng, Physalis, Indigo Daisy, Cimicifuga, Cinnabar, Purple Pearl, Honeysuckle, Folium Isatidis, Radix Isatidis, Tiankui Seed, Duck Tuocao, The medicinal residues of Viola and Andrographis paniculata are in the same weight ratio;

[0037] The organic material decomposing agent is ammonium sulfate,

[0038] The biological fermentation strains are Bacillus amyloliquefaciens and Trichoderma harzianum in the same weight ratio,

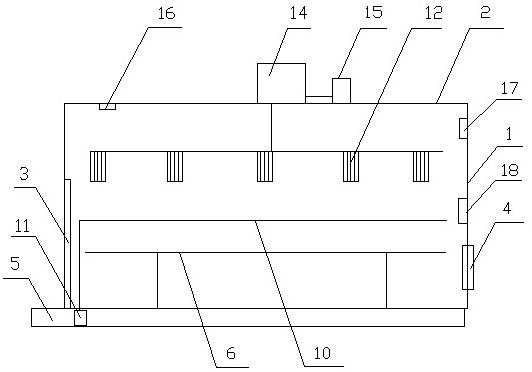

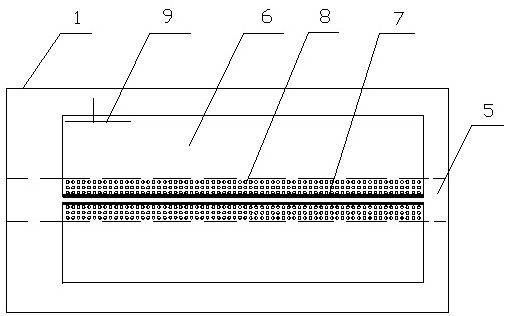

[0039](2) The plant straw does not need to be crushed, and it is directly put into the non-closed sunlight tile fermentation workshop t...

Embodiment 2

[0043] (1) Prepare plant straw, traditional Chinese medicine residue, organic material decomposing agent, and biological fermentation bacteria in a weight ratio of 75:24.8:0.1:0.1 for use;

[0044] Wherein the plant straw is wheat straw, corn straw, rape straw and broad bean straw in a weight ratio of 1:2:1:1.5;

[0045] The traditional Chinese medicine dregs include forsythia, ginseng, scrophulariaceae, Baiwei, rhubarb, shegan, licorice, Qinpi, Physalis, puffball, Qingdai, Cimicifuga, thistle, Burnet, cinnabar, purple pearl, honeysuckle, The medicinal residues of Daqingye, Smilax smilax, Tiankuizi, Qingmuxiang and Zihuadiding are in the same weight ratio;

[0046] The organic material decomposing agent is ammonium sulfate,

[0047] The biological fermentation strains are Bacillus amyloliquefaciens and Trichoderma harzianum in the same weight ratio,

[0048] (2) The plant straw does not need to be crushed, and it is directly put into the non-closed sunlight tile fermentation...

Embodiment 3

[0052] (1) Prepare plant straw, traditional Chinese medicine residue, organic material decomposing agent, and biological fermentation bacteria in a weight ratio of 75:24.8:0.1:0.1 for use;

[0053] Wherein the plant straw is wheat straw, rice straw, rape straw and cotton straw in a weight ratio of 1:2:1:1.5;

[0054] The traditional Chinese medicine dregs include forsythia, ginseng, Guanzhong, Baiwei, rhubarb, shegan, licorice, Qinpi, red rattan, puffball, leaking reed, cohosh, big thistle, cinnabar, purple pearl, honeysuckle, big green leaf The medicinal residues of Radix Isatidis, Radix Ginzae, Dactylacia chinensis, Zihua Diding, Andrographis paniculata are in the same weight ratio;

[0055] The organic material decomposing agent is ammonium sulfate,

[0056] The biological fermentation strains are Bacillus amyloliquefaciens and Trichoderma harzianum in the same weight ratio,

[0057] (2) The plant straw does not need to be crushed, and it is directly put into the unenclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com