Broadband adjustable graphene electromagnetic wave absorbing material and preparation method thereof

An absorbing material, graphene technology, applied in the direction of electrical components, magnetic/electric field shielding, antennas, etc., can solve the problems that cannot satisfy the active adjustable electromagnetic wave absorption performance and the limitation of the use range, and achieve excellent comprehensive performance. High antioxidant, anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

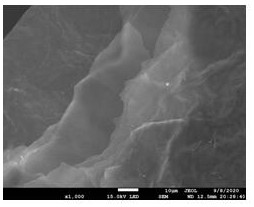

[0046] 1) Through the improved Hummer's method, using natural graphite flakes as raw materials, small pieces of graphene oxide (SGO) were prepared by controlling the size of natural flake graphite, the amount of oxidant, the reaction temperature, the oxidation time and the subsequent centrifugation process to control the size. ), with a size of 40–50 μm (SGO).

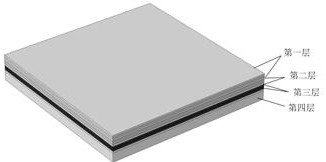

[0047] 2) First, dissolve 250 mg of graphene oxide in ethanol, and then prepare a 18cm*18cm square polytetrafluoroethylene mold, slowly drop the graphene oxide dispersion into the mold, and spin-coat the graphene oxide The dispersion liquid is evenly distributed in the mold, so that the thickness of the graphene oxide film is about 15 μm, and then put into an oven for drying at 60° C., and two graphene oxide films are prepared by the same method.

[0048] 3) Lithium perchlorate (LiClO 4 ), and polymethyl methacrylate (PMMA) in acetonitrile solvent, heated at 50°C and mixed evenly, poured the mixed solution into a 18cm...

Embodiment 2

[0061] 1) Through the improved Hummer's method, using natural graphite flakes as raw materials, small pieces of graphene oxide (SGO) were prepared by controlling the size of natural flake graphite, the amount of oxidant, the reaction temperature, the oxidation time and the subsequent centrifugation process to control the size. ), with a size of 40–50 μm (SGO).

[0062] 2) First, dissolve 400 mg graphene oxide in ethanol, then prepare a 18cm*18cm square polytetrafluoroethylene mold, slowly drop the graphene oxide dispersion into the mold, and spin coat the graphene oxide The dispersion liquid is evenly distributed in the mold, so that the thickness of the graphene oxide film is about 30 μm, and then put into an oven for drying at 60° C., and two graphene oxide films are prepared by the same method.

[0063] 3) Add lithium bistrifluoromethylsulfonylamide (LiTSFI) and polyethylene oxide (PEO) into acetonitrile solvent, heat at 50°C and mix well, pour the mixed solution into a 18c...

Embodiment 3

[0072]1) Through the improved Hummer's method, using natural graphite flakes as raw materials, small pieces of graphene oxide (SGO) were prepared by controlling the size of natural flake graphite, the amount of oxidant, the reaction temperature, the oxidation time and the subsequent centrifugation process to control the size. ), with a size of 40–50 μm (SGO).

[0073] 2) First, dissolve 250 mg of graphene oxide in ethanol, and then prepare a 18cm*18cm square polytetrafluoroethylene mold, slowly drop the graphene oxide dispersion into the mold, and spin-coat the graphene oxide The dispersion liquid is evenly distributed in the mold, so that the thickness of the graphene oxide film is about 15 μm, and then placed in an oven for drying at 60 ° C, and two graphene oxide films are prepared by the same method.

[0074] 3) Add lithium bistrifluoromethylsulfonylamide (LiTSFI) and polyethylene oxide (PEO) into acetonitrile solvent, heat at 50°C and mix well, pour the mixed solution int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com