Biomass carbon dot/wood composite photocatalytic material and preparation method and application thereof

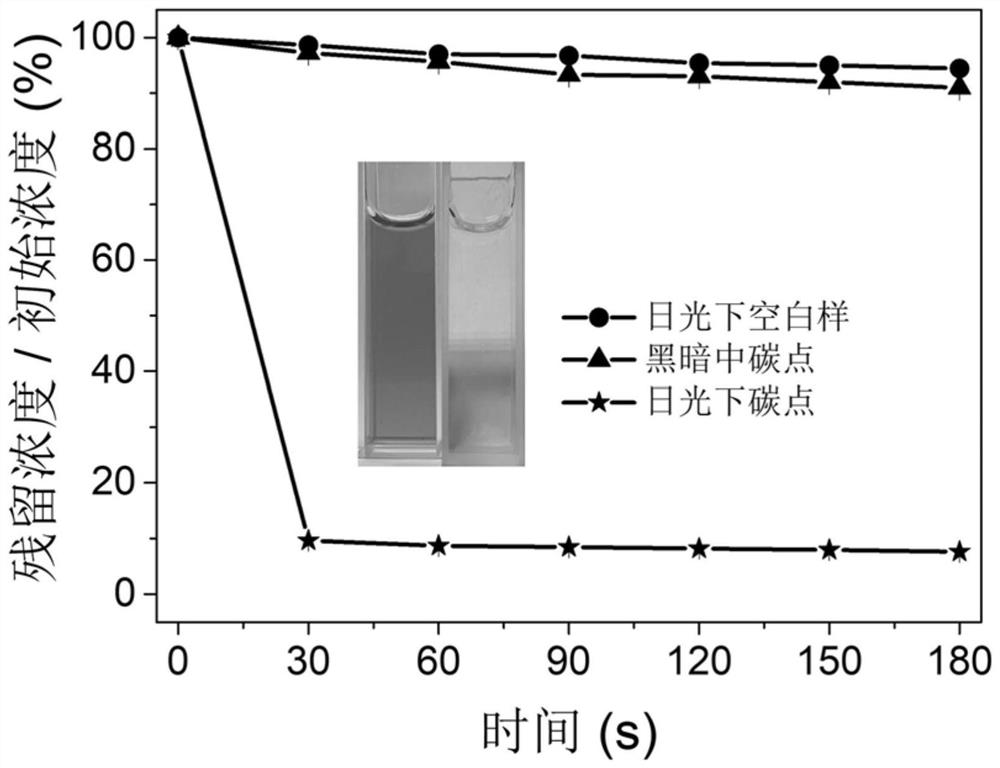

A technology of composite photocatalysis and biomass carbon, which is applied in the field of photocatalytic materials, can solve the problems of difficult recovery of metal components, difficulty in realizing industrialization, complicated process, etc., and achieve the effect of simple operation, efficient degradation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

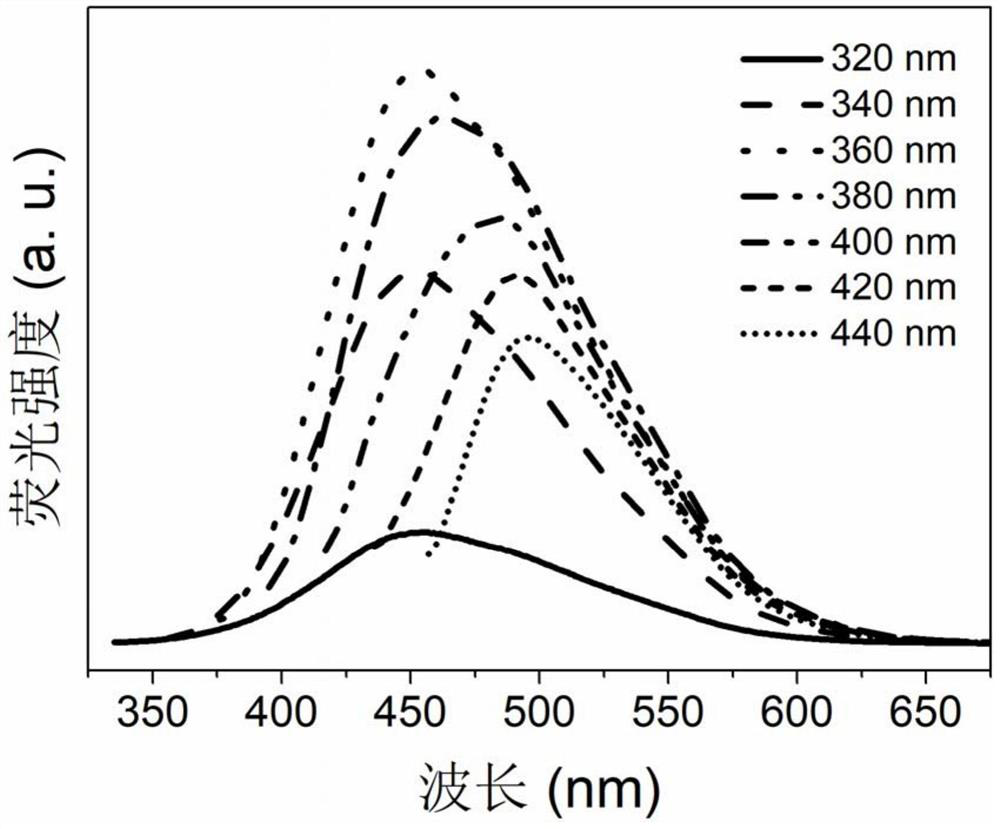

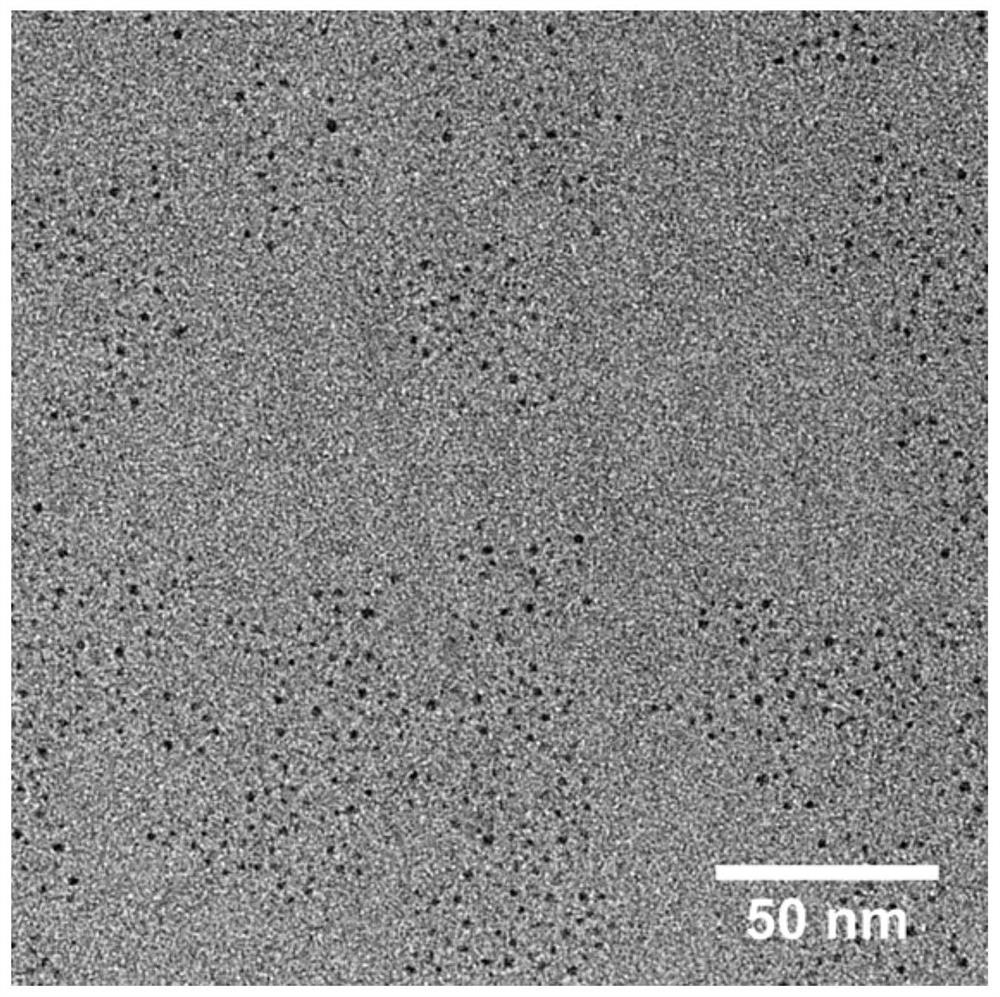

[0033] Dilute H with a mass fraction of 1% 2 SO 4 , under the condition of 60°C, the wood powder was pretreated for 1h, then adding NaOH with a mass fraction of 10%, the solid-to-liquid ratio was 1:12 (g:mL), and the wood powder was leached at 110°C Suction filtration, adjust the pH of the filtrate to neutral with HCl with a concentration of 6 mol / L. Then heat and evaporate the water in the filtrate in a boiling water bath, after cooling, add a certain amount of ethanol with a mass fraction of 95%, and precipitate to obtain xylose. Accurately weigh 0.2 g of xylose, and fully dissolve it in 10 mL of 2% thionyl chloride solution by volume to form an initial mixed solution. The mixed solution was subjected to hydrothermal treatment, the treatment temperature was set at 200° C., and the treatment time was 6 hours. After the reaction was completed and cooled to room temperature, a yellow liquid product was obtained. The product is centrifuged and dialyzed to remove large carbon ...

specific Embodiment 2

[0036] Dilute H with a mass fraction of 1% 2 SO 4, under the condition of 60°C, the wood powder was pretreated for 1h, then adding NaOH with a mass fraction of 10%, the solid-to-liquid ratio was 1:12 (g:mL), and the wood powder was leached at 110°C Suction filtration, adjust the pH of the filtrate to neutral with HCl with a concentration of 6 mol / L. Then heat and evaporate the water in the filtrate in a boiling water bath, after cooling, add a certain amount of ethanol with a mass fraction of 95%, and precipitate to obtain xylose. Accurately weigh 0.1 g of xylose, and fully dissolve it in 10 mL of 5% thionyl chloride solution by volume to form an initial mixed solution. The mixed solution was subjected to hydrothermal treatment, the treatment temperature was set at 160° C., and the treatment time was 8 hours. After the reaction was completed, after cooling to room temperature, a yellow liquid product was obtained. The product is centrifuged and dialyzed to remove large carb...

specific Embodiment 3

[0038] Dilute H with a mass fraction of 1% 2 SO 4 , under the condition of 60°C, the wood powder was pretreated for 1h, then adding NaOH with a mass fraction of 10%, the solid-to-liquid ratio was 1:12 (g:mL), and the wood powder was leached at 110°C Suction filtration, adjust the pH of the filtrate to neutral with HCl with a concentration of 6 mol / L. Then heat and evaporate the water in the filtrate in a boiling water bath, after cooling, add a certain amount of ethanol with a mass fraction of 95%, and precipitate to obtain xylose. Accurately weigh 0.3g of xylose, and fully dissolve it in 10mL of 1% thionyl chloride solution by volume to form an initial mixed solution. The mixed solution was subjected to hydrothermal treatment, the treatment temperature was set at 220° C., and the treatment time was 4 hours. After the reaction was completed and cooled to room temperature, a yellow liquid product was obtained. The product is centrifuged and dialyzed to remove large carbon pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com