Method for manufacturing a structural color filter

A technology of optical filter and structural color, applied in the direction of optical filter, optics, optical components, etc., can solve problems such as limiting application scenarios, increasing process complexity and difficulty, and complex processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

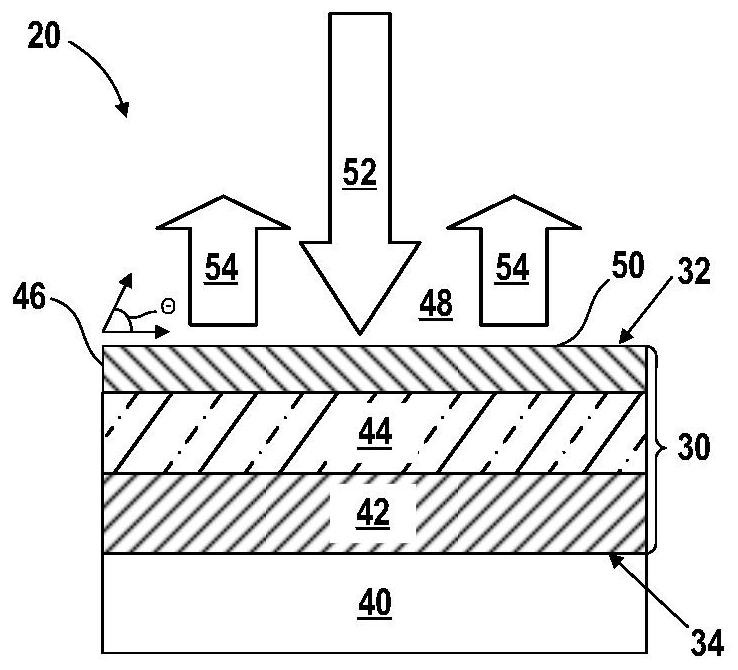

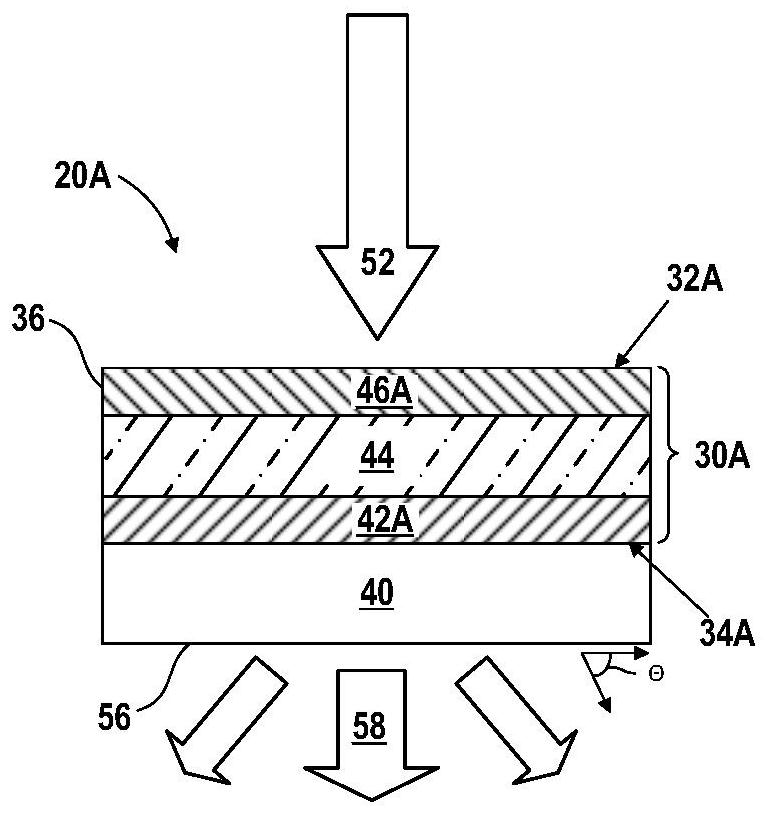

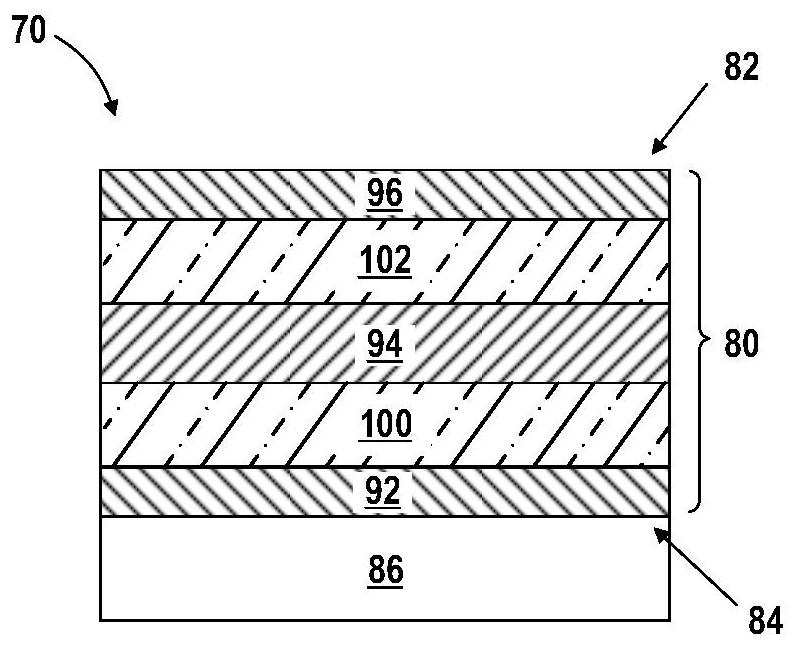

[0107] attached Figure 5A It is a schematic diagram of a structural color filter device processed according to the solution method described in the present invention, as shown in the figure, it is formed by sequentially electroplating Au / Cu on a crystalline silicon (Si) substrate 2 O / Au three-layer film (MDM stacked film).

[0108] The following raw materials were used in processing: acetone (ACS grade, Fisher Scientific), methanol (ACS grade, Fisher Scientific), isopropanol (ACS grade, Fisher Scientific), buffered hydrofluoric acid (BHF) (Transene Inc.), hydrofluoric acid acid (HF) (49%, Transene Inc.), gold(III) chloride trihydrate (HAuCl 4 3H2O) (>99.9%, Sigma-Aldrich), potassium sulfate (K 2 SO 4 ) (ACS grade, Fisher Scientific), potassium chloride (KCl) (ACS grade, Fisher Scientific), sulfuric acid (H 2 SO 4 ) (0.1M concentrate for IC, Sigma-Aldrich), copper(II) sulfate pentahydrate (CuSO 4 ·5H 2 O) (ACS grade, Avantor), citric acid (>99.5% ACS grade, Sigma-Aldric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap