Organic silicon modified bio-based waterborne polyurethane resin composition and preparation method thereof

A technology of polyurethane resin and water-based polyurethane, which is applied in the field of organosilicon-modified bio-based water-based polyurethane resin composition and its preparation, can solve the problems of folding resistance, wear resistance, heat resistance, mechanical properties, storage performance, biodegradability and Constant temperature and humidity performance and other problems are not high enough, performance defects, limiting the application of water-based polyurethane materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The composition of organosilicon-modified bio-based water-based polyurethane resin composition is shown in the table below:

[0066] Table 1

[0067] raw material name Weight (unit: gram) Korean SK bio-based polyol H-2000 (number average molecular weight 2000) 140 Polytetrahydrofuran ether glycol (number average molecular weight 2000) 140 DMPA 5 Dicyclohexylmethane diisocyanate 100 1,6-diisocyanate 20 Catalyst BICAT 8118 0.2 acetone 470 Methylpropanediol 6 Polypropylene oxide / ethylene oxide ether modified silicone oil diol (number average molecular weight 6000) 30 ethanolamine 3 Triethylamine 3.76 Sodium ethylenediaminoethanesulfonate 50% aqueous solution (A-95) 18 Deionized water 686 Ethylenediamine 5.23

[0068] The preparation steps of the organosilicon modified bio-based waterborne polyurethane resin of the present embodiment are as follows:

[0069] 1) Put 140g of Ko...

Embodiment 2

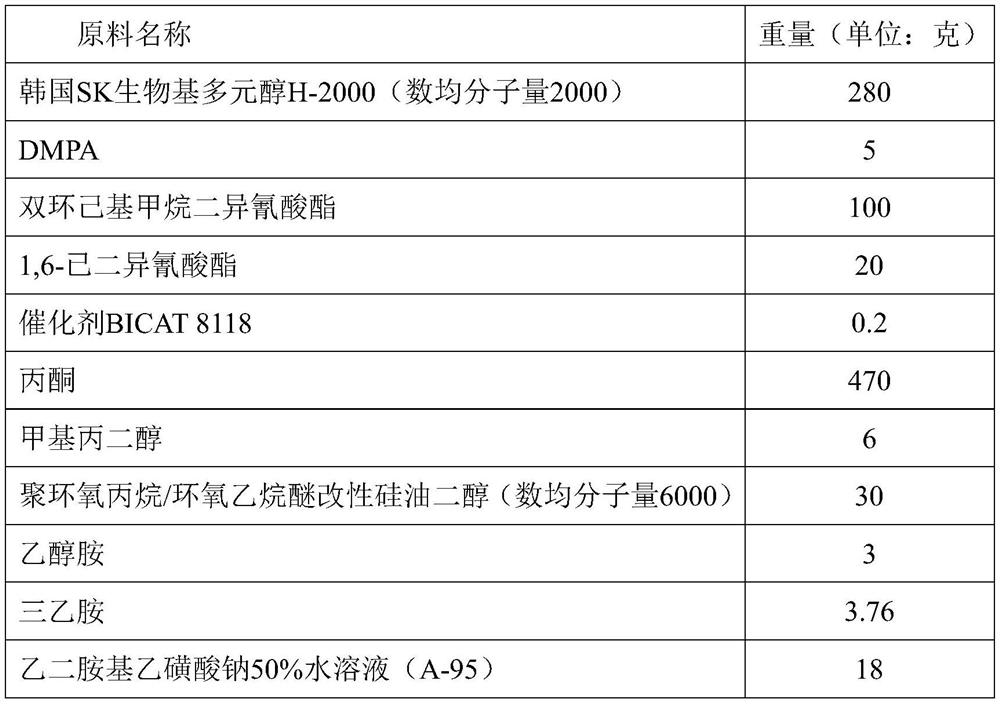

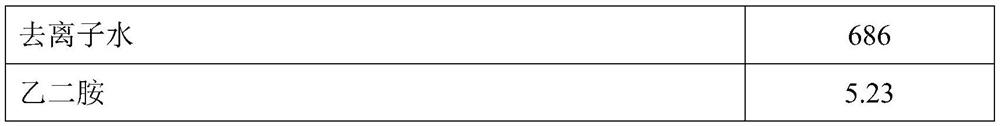

[0073] The composition of organosilicon-modified bio-based water-based polyurethane resin composition is shown in the table below:

[0074] Table 2

[0075]

[0076]

[0077] The preparation steps of the organosilicon modified bio-based waterborne polyurethane resin of the present embodiment are as follows:

[0078] 1) Put 280g of Korean SK bio-based polyols, 5g of DMPA, and 0.1g of catalyst BICAT 8118 into the reactor, and stir at 50°C for 20 minutes until evenly stirred;

[0079] 2) Put 100g of dicyclohexylmethane diisocyanate and 20g of 1,6-hexamethylene diisocyanate into the reaction kettle, strictly control the reaction temperature between 85 and 90°C, and after 2.5 hours of normal pressure reaction, take samples to measure the NCO content. When the NCO content is lower than After 6.72%, drop the temperature to 62°C and put in 150 grams of acetone, stir evenly, add 6g of methyl propylene glycol, 3g of ethanolamine, 30g of polypropylene oxide / ethylene oxide ether mo...

Embodiment 3

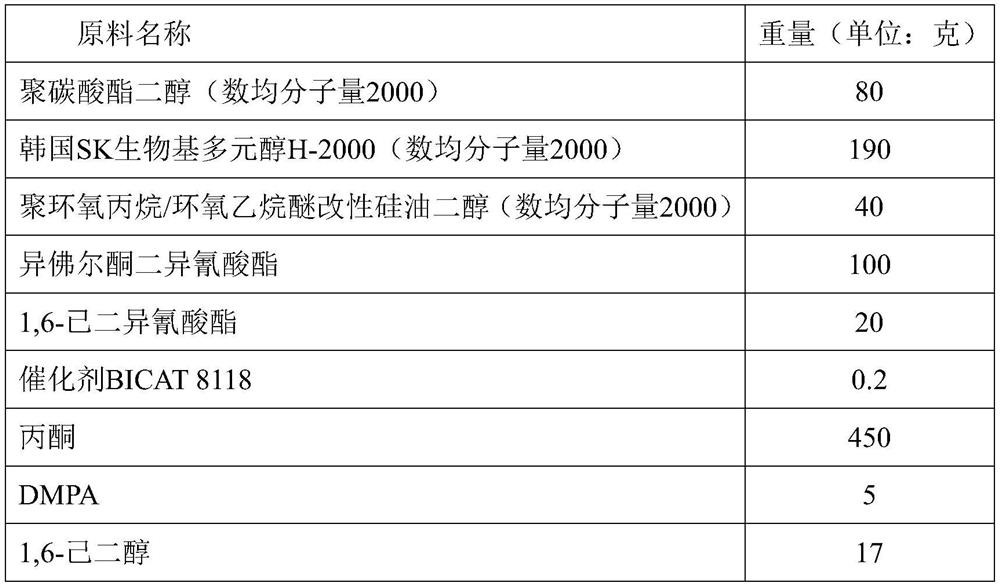

[0082] The composition of organosilicon-modified bio-based water-based polyurethane resin composition is shown in the table below:

[0083] table 3

[0084]

[0085]

[0086] The preparation steps of the organosilicon modified bio-based waterborne polyurethane resin of the present embodiment are as follows:

[0087] 1) Put 80g of polycarbonate diol, 190g of Korean SK bio-based polyol, 40g of polypropylene oxide / ethylene oxide ether modified silicone oil diol, and 0.1g of catalyst BICAT 8118 into the reactor, and stir at 50°C for 20 minutes , to stir evenly;

[0088] 2) Put 100g of isophorone diisocyanate and 20g of 1,6-hexamethylene diisocyanate into the reactor, strictly control the reaction temperature between 85 and 90°C, and react at normal pressure for 2.5 hours, then take samples to measure the NCO content, when the NCO content is low After 8.11%, cool down to 62°C and put in 150g of acetone, stir evenly, add 5g of DMPA, 17g of 1,6-hexanediol, continue to react a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com