Solid-state lithium battery and electrode-diaphragm layer interface improvement method and application thereof

A technology of solid lithium and diaphragm layer, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, and electrolyte batteries, etc. It can solve the problems of mismatched electrochemical activity, poor battery performance, and hindered ion transmission, etc., so as to improve battery capacity retention efficiency, improved cycle stability, and excellent transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

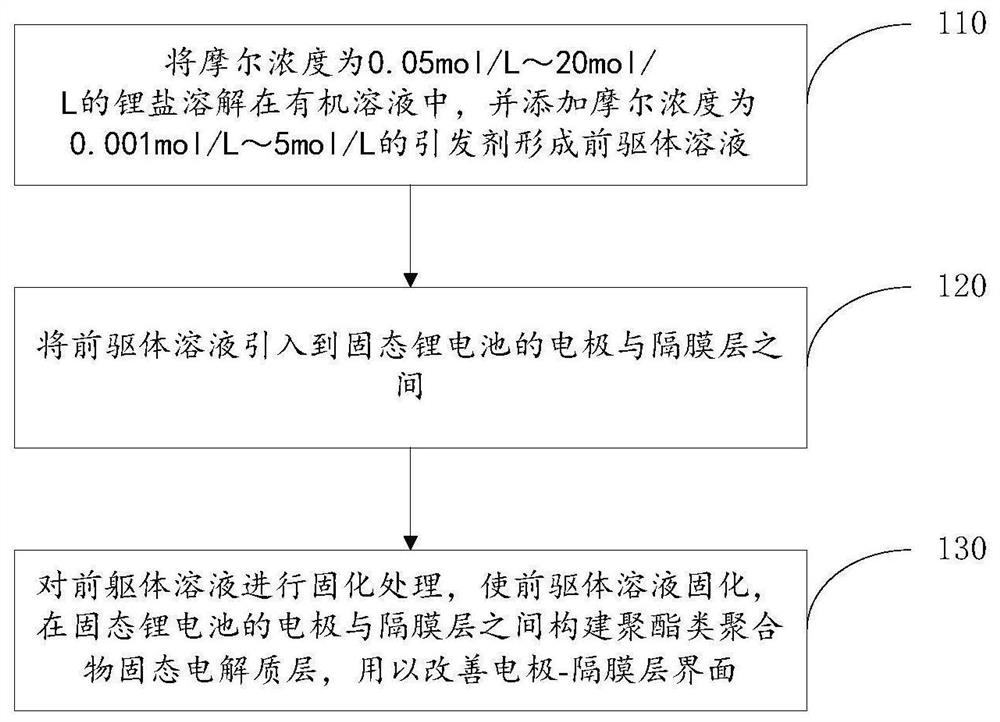

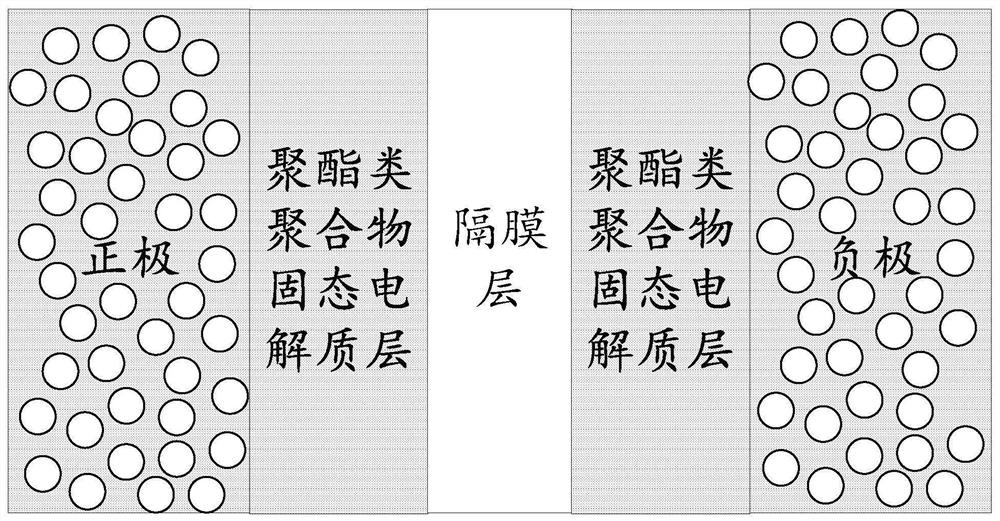

Method used

Image

Examples

Embodiment 1

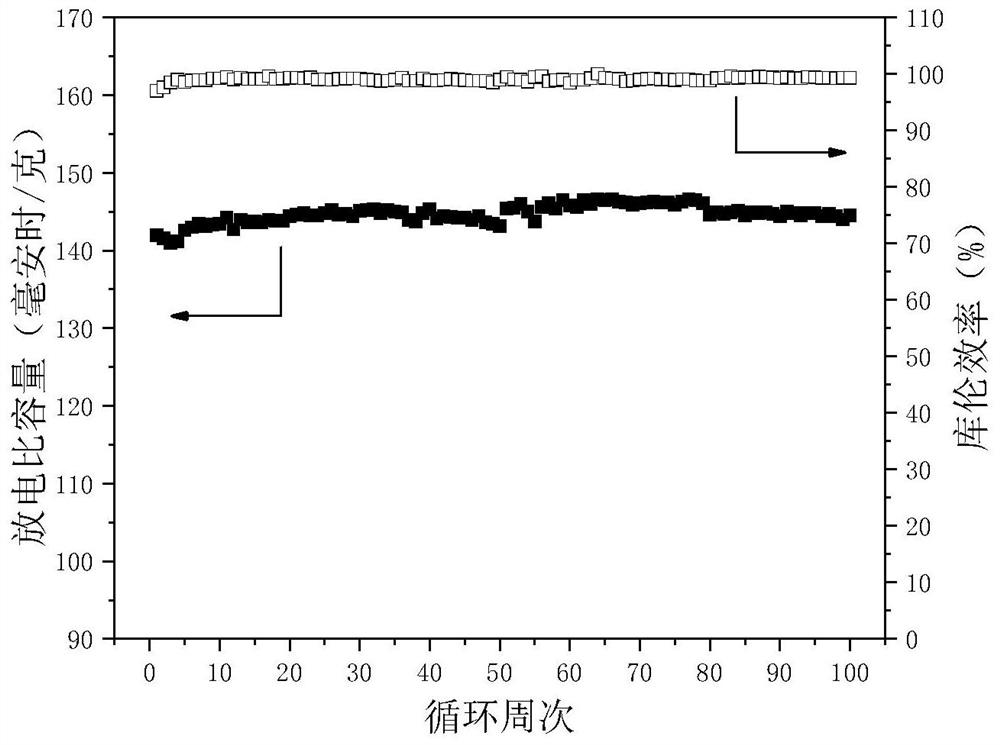

[0076]In this embodiment, polyvinylene carbonate is used to modify the lithium cobalt oxide pole piece to prepare a polyethylene oxide (PEO)-based polymer solid-state lithium battery.

[0077]1. Take 3.5 g of LiTFSI, dissolve it in 30 ml of VC, and add 10 mg of AIBN to prepare a precursor solution for later use;

[0078]2. According to the mass ratio of lithium cobaltate (LCO), polyvinylidene fluoride (PVDF), and super P, the mass ratio is 8:1:1, and the raw materials are dissolved in N-methylpyrrolidone (NMP), stirred into a slurry, and passed Coating, punching, weighing, drying, etc., prepare an untreated positive pole piece with a diameter of 12 mm, and transfer it to the glove box for later use;

[0079]3. According to the EO:Li ratio of 18, a PEO-LiTFSI polymer solid electrolyte membrane with a diameter of 16.2 mm and a thickness of 200 microns was prepared according to the solution casting method, for use;

[0080]4. In a glove box filled with high-purity argon, add 20 microliters of the ...

Embodiment 2

[0084]In this embodiment, polyvinyl ethylene carbonate is used to modify lithium nickel cobalt manganate pole pieces to prepare a polyacrylonitrile (PAN)-based polymer system all-solid battery.

[0085]1. Take 3.5 g of LiDFOB, dissolve it in 200 ml of ethylene ethylene carbonate, add 20 mg of BPO to prepare a precursor solution for later use;

[0086]2. According to the mass ratio of nickel cobalt manganate (NCM622), polyvinylidene fluoride (PVDF), and super P at a mass ratio of 8:1:1, dissolve the raw materials in N-methylpyrrolidone (NMP) and stir to form a slurry , Through the processes of coating, punching, weighing, drying, etc., an untreated positive pole piece with a diameter of 12 mm is prepared and transferred to the glove box for later use;

[0087]3. According to the N:Li ratio of 18, PAN-LiClO with a diameter of 16.2 mm and a thickness of 300 microns was prepared according to the solution casting method4Polymer solid electrolyte membrane, spare;

[0088]4. In a glove box filled with...

Embodiment 3

[0091]In this embodiment, polymethyl methacrylate is used to modify lithium cobalt oxide pole pieces to prepare an inorganic system all-solid-state battery.

[0092]1. Take 3.5 g of LiTFSI, dissolve it in 30 ml of methyl methacrylate, and add 10 mg of AIBN to prepare a precursor solution for later use;

[0093]2. According to the mass ratio of lithium cobaltate (LCO), polyvinylidene fluoride (PVDF), and super P, the mass ratio is 8:1:1, and the raw materials are dissolved in N-methylpyrrolidone (NMP), stirred into a slurry, and passed Coating, punching, weighing, drying, etc., prepare an untreated positive pole piece with a diameter of 12 mm, and transfer it to the glove box for use;

[0094]3. Prepare a lithium lanthanum zirconium oxide (LLZO) solid electrolyte sheet with a diameter of 16.2 mm and a thickness of 200 mm according to the hot pressing method, for use;

[0095]4. In a glove box filled with high-purity argon gas, take 20 microliters of the precursor solution and drop it on the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com