Waste salt resourceful treatment method

A treatment method and resource recovery technology, applied in the field of industrial waste salt resource recovery process, can solve problems such as low decomposition temperature, poor gas-solid contact, secondary pollution, etc., and achieve green harmless treatment and resource utilization technology, Solve the problem of secondary pollution, the effect of high decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Concentrated brine produced from a pure water processing plant, wastewater with a total salt content of about 8%.

[0063] 2. Add raw coal and coal-water slurry additives made into small pieces of coal by rolling screens, crushers, etc., send them to a ball mill to grind them into liquid, stir through an underground tank in the middle, and pass through a vibrating screen to obtain a concentration of 50- The 75% coal-water slurry is transported to the finished product tank through the slurry pump, stirred and set aside.

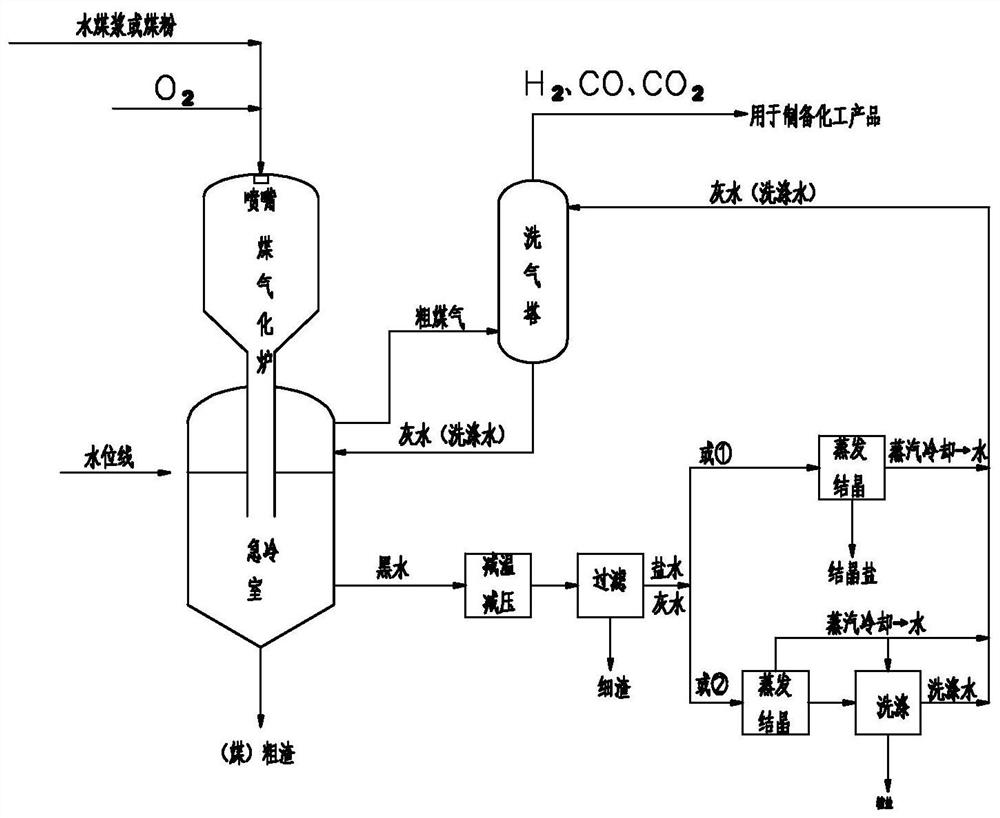

[0064] 3. After the compressed oxygen is sprayed into the gasification furnace through a special nozzle together with the coal-water slurry, the gasification and cracking reaction is carried out under the conditions of 1350-1450 °C, 1.9-2.0 MPa high temperature and high pressure for 5 seconds to generate crude gas (CO , CO2, H2, N2 and H 2 Substances such as S can further produce hydrogen, CO 2 and other products), molten cinder ash, molten salt li...

Embodiment 2

[0069] 1. A production plant produces epichlorohydrin by the glycerin chlorination method, which produces a large amount of waste salt, which contains about 2% organic matter. Dissolve the waste salt in water and adjust the pH value to 7-10.

[0070] 2. Add raw coal and coal-water slurry additives made into small pieces of coal by rolling screens, crushers, etc., send them to a ball mill to grind them into liquid, stir through an underground tank in the middle, and pass through a vibrating screen to obtain a concentration of 50- The 75% coal-water slurry is transported to the finished product tank through the slurry pump, stirred and set aside.

[0071] 3. After the oxygen is compressed, it passes through a special nozzle together with the coal-water slurry, and is sprayed into the gasification furnace, and the gasification and cracking reactions are carried out under the conditions of 1200-1300 ° C, 1.3 MPa high temperature and high pressure for 8 seconds to generate crude gas...

Embodiment 3

[0076] 1. The saturated waste brine solution obtained from a certain PPS production plant, and the pH value is adjusted to 7-10.

[0077] 2. Add raw coal and coal-water slurry additives made into small pieces of coal by rolling screens, crushers, etc., send them to a ball mill to grind them into liquid, stir through an underground tank in the middle, and pass through a vibrating screen to obtain a concentration of 50- The 75% coal-water slurry is transported to the finished product tank through the slurry pump, stirred and set aside.

[0078] 3. After the oxygen is compressed, it passes through a special nozzle together with the coal-water slurry, and is sprayed into the gasification furnace, and the gasification and cracking reactions are carried out under the conditions of 1250-1350 ° C, 4.0 MPa high temperature and high pressure for 6 seconds to generate crude gas (CO, CO2 , H2, N2 and H 2 S and other substances, raw material gas for the synthesis of methanol), molten cind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com