Compound protein and preparation method and application thereof

A technology of compounding protein and keratin, which is applied in the direction of single-component protein rayon, textile and papermaking, rayon made of viscose, etc., can solve the problems of easy loss of protein and low protein content, and achieve great application value , the preparation method is simple, the operation is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

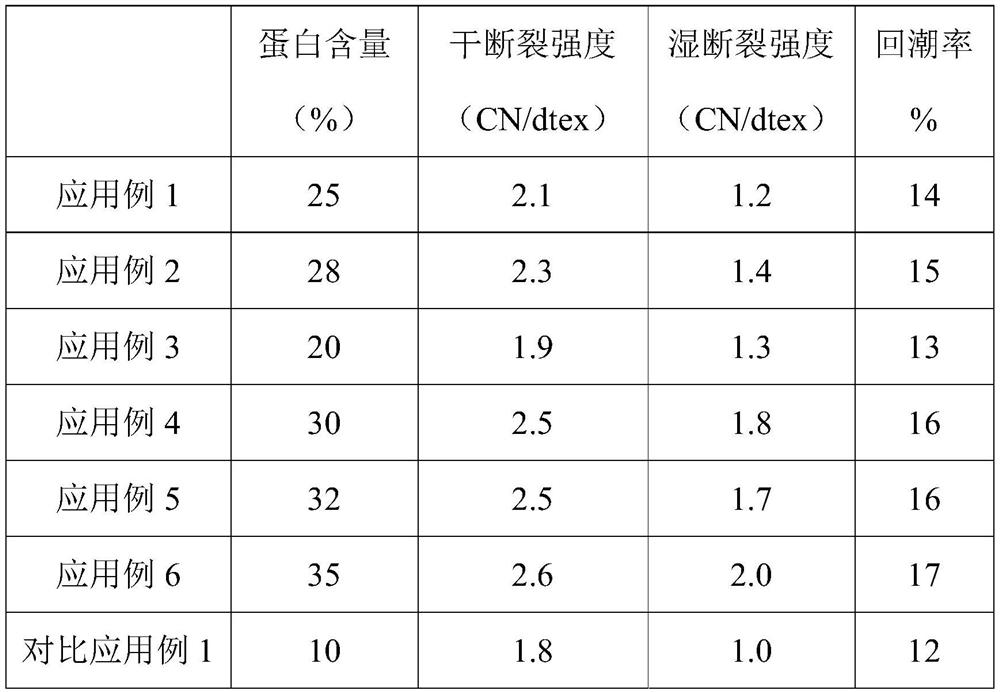

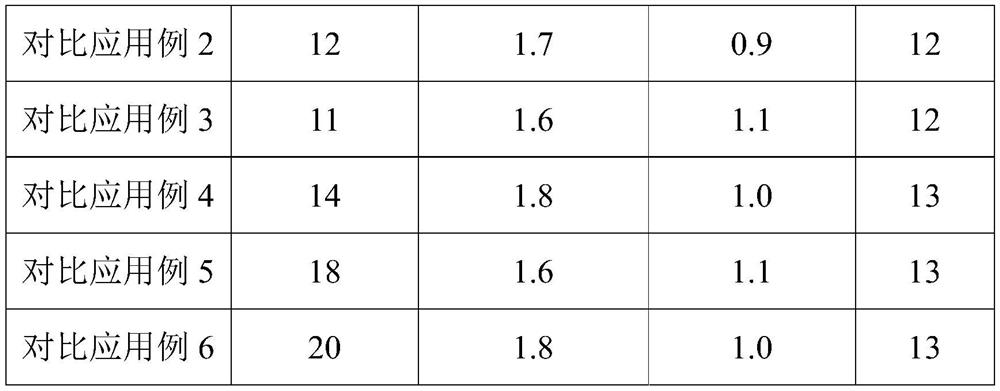

Examples

preparation example 1

[0083] A kind of zein supernatant, its preparation method is as follows:

[0084] (1) Mix water and corn yellow powder (produced by Hebei Guangyu Starch Sugar Industry Co., Ltd.) with a mass ratio of 1:6.5 at 35°C for 0.5h, and filter with a plate and frame filter press to obtain a liquid-carrying rate of 40%. Moist corn raw material;

[0085] (2) the wet corn raw material obtained in step (1) and ethanol are 60 ℃, stirring speed under the condition of 280r / min with the mass percentage of 1:0.75:2.5 being 6% sodium hydroxide aqueous solution, Mix for 2 hours and filter to obtain the zein supernatant.

preparation example 2

[0087] A kind of wool keratin supernatant, its preparation method is as follows:

[0088] (1) the mass ratio is 1:10 dispersant solution (solvent is water, and the carbonamide that comprises concentration is 2mol / L, concentration is that 1mol / L benzene sulfonate and concentration are the mixed solution of 1mol / L sulfite ) and wool were mixed at 70°C for 1.75h, and filtered by a centrifuge to obtain wet wool;

[0089] (2) Mix the wet wool obtained in step (1) with a mass ratio of 1:4.5 and 9% aqueous sodium hydroxide solution at 60° C. and a stirring speed of 200 r / min for 2 hours, filter, Obtain the wool keratin supernatant.

preparation example 3

[0091] A kind of zein supernatant, its preparation method is as follows:

[0092] (1) Mix water and corn yellow powder (produced by Hebei Guangyu Starch Sugar Industry Co., Ltd.) with a mass ratio of 1:6 at 30°C for 0.25h, and filter with a plate and frame filter press to obtain a liquid carrying rate of 30%. Moist corn raw material;

[0093] (2) the wet corn raw material and ethylene glycol that the mass percentage that is 1:0.5:1 is 5% sodium hydroxide aqueous solution, step (1) obtains at 40 ℃, stirring speed is 150r / min Mix under the condition for 1.5h, filter to obtain the zein supernatant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com