Method for preparing super-hydrophobic coating through water-based RAFT miniemulsion polymerization

A mini-emulsion polymerization, super-hydrophobic coating technology, applied in coatings, antifouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of health and natural environment threats, difficult natural degradation, etc. Controllable, simple and easy-to-obtain effects

Active Publication Date: 2021-02-19

ZHEJIANG SCI-TECH UNIV

View PDF9 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the good stability of fluorine-containing compounds with long carbon chains, they are difficult to degrade naturally and have certain bioaccumulation, so they pose a potential serious threat to human health and the natural environment, which also makes perfluorooctanoic acid (PFOA) and perfluorinated Octane Sulfonyl Compounds (PFOS) Banned Worldwide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

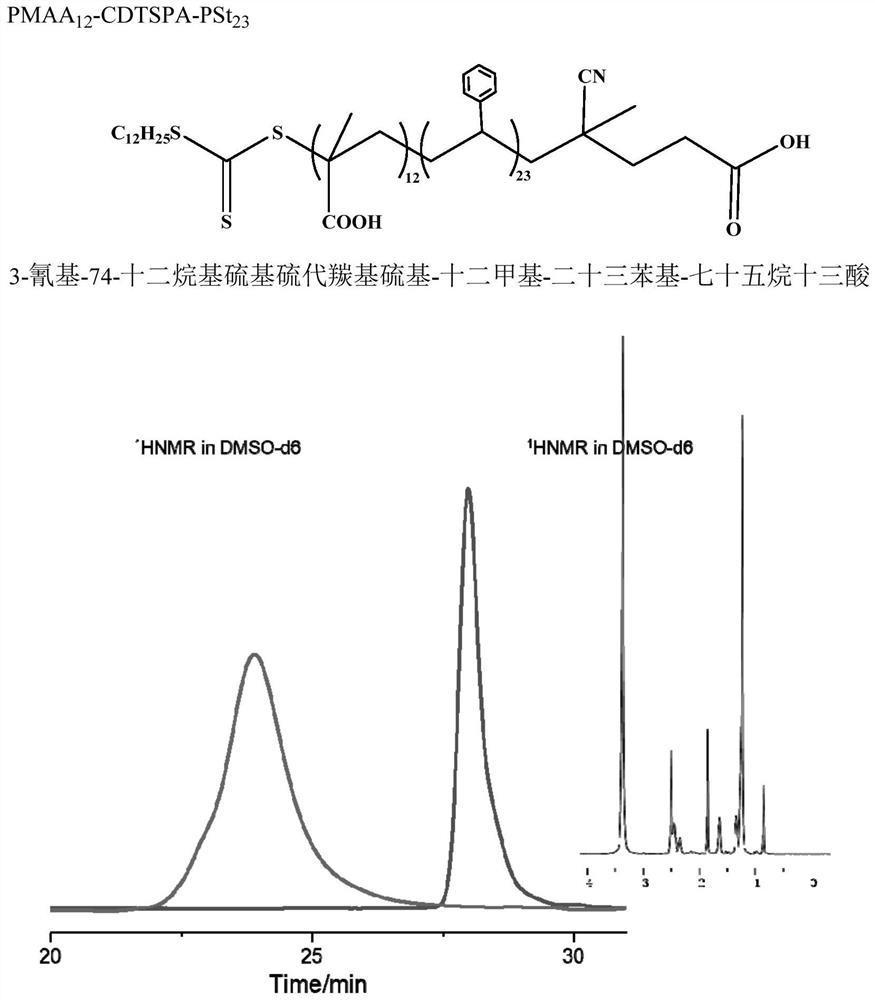

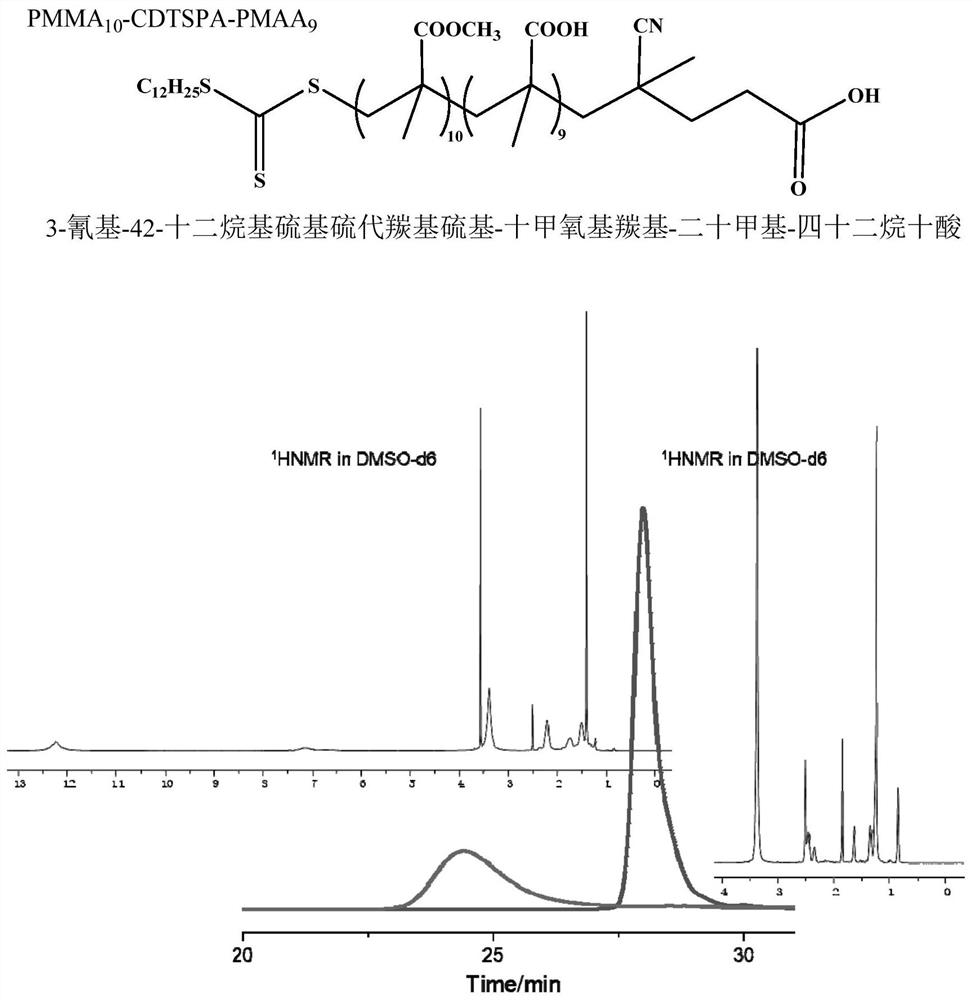

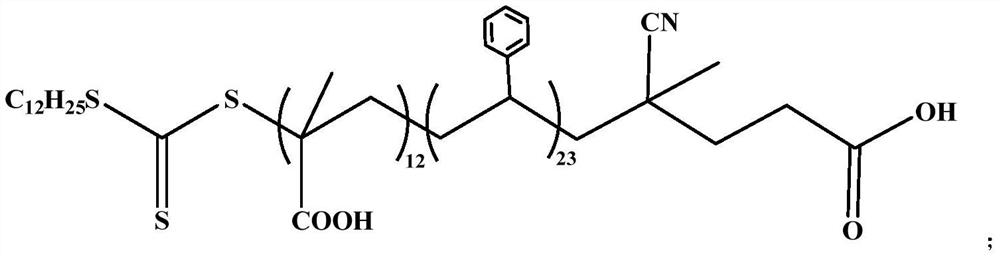

The invention discloses a method for preparing a super-hydrophobic coating through water-based RAFT miniemulsion polymerization, which comprises the following steps: by using water as a solvent and anamphiphilic reversible addition fragmentation chain transfer (RAFT) macromolecular reagent as a surfactant, synthesizing a polymer of an acrylate monomer and a terminated modified polysiloxane (PDMS)monomer by miniemulsion polymerization. The copolymer is controllable in molecular weight and high in silicon content, a polymer interpenetrating network is formed by adding a cross-linking agent, the contact angle of a coating of the copolymer on glass, wood, a steel plate, plastic and other base materials is larger than 150 degrees, the rolling angle of the coating is smaller than 10 degrees, and the coating has excellent hydrophobicity. The method is simple in preparation, water is used as a solvent, no emulsifier is contained, and fluorine, micro-nano particle potential hazards and organic solvent pollution are avoided. The coating is especially suitable for antifouling, anticorrosion, anti-icing, anti-fog and the like in the aerospace field.

Description

technical field [0001] The invention relates to the technical field of preparation of superhydrophobic coatings, in particular to a method for preparing superhydrophobic coatings through aqueous RAFT mini-emulsion polymerization. Background technique [0002] In recent years, domestic and foreign scientific research groups and industrial production industries have paid more and more attention to the research and development of new coating materials, especially bionic intelligent coating materials. Natural selection, the natural world has endowed researchers with extensive research inspiration. Inspired by biological characteristics such as the lotus leaf effect and water strider legs in nature, super-hydrophobic coatings have received extensive attention and research in recent years. Due to its special surface wettability and low surface energy, super-hydrophobic coatings have multi-functional comprehensive properties such as ice resistance, corrosion resistance, anti-foulin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D151/08C09D133/12C09D5/16C09D5/08C08F283/12C08F220/18C08F220/14C08F220/28C08F230/08C08F220/58C08F2/22

CPCC09D151/08C09D143/04C09D5/1662C09D5/08C08F283/124C08F220/1804C08F220/14C08F2/22C08F2400/00C08F2438/03C08F220/28C08F220/58C08F230/085

Inventor 戚栋明靳琳琳李家炜

Owner ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com