Implantable ligament substitute material based on oriented carbon nanotube fibers and preparation method of implantable ligament substitute material

A technology for orienting carbon nanotubes and carbon nanotube fibers, applied in the field of medical materials, can solve the problems of poor biointegration, difficult autologous tissue regeneration, and bone tissue wear, etc., to promote bone tissue integration, promote autologous tissue regeneration and bone tissue. Integrated, fatigue-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

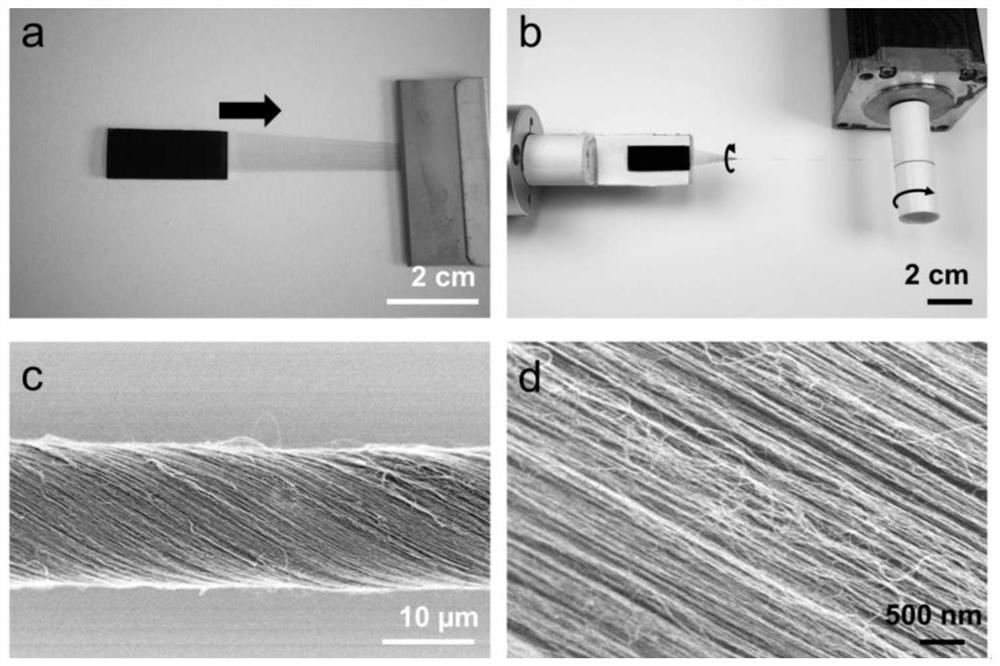

[0028] Embodiment 1, preparation of primary helically oriented carbon nanotube fibers

[0029] (1) Preparation of primary helically oriented carbon nanotube fibers by chemical vapor deposition

[0030] With the silicon wafer as the substrate, the electron beam evaporation coating apparatus successively deposits Al with a thickness of 10nm on the silicon wafer. 2 o 3 and Fe with a thickness of 1 nm as a catalyst. Put the catalyst into a tube furnace, use ethylene, argon and hydrogen as the carbon source, carrier gas and reducing gas respectively, and control the flow rate to be 90 sccm, 400 sccm and 30 sccm respectively, at 740 o C for 10 minutes to obtain a highly oriented carbon nanotube array on the substrate. Use a blade to pull out carbon nanotube ribbons from the array, collect and fix them at the end of the spindle, and rotate at a constant speed to continuously obtain oriented helical carbon nanotube fibers ( figure 1 a, b). Control the motor speed to 1000 rpm, and...

Embodiment 2

[0034] Embodiment 2, preparation of two-stage helically oriented carbon nanotube fibers

[0035] 50 first-stage helical carbon nanotube fibers with a length of 20 cm and a diameter of 10 μm are arranged in parallel, gathered together in one place, fixed at both ends, one of which is fixed on the electric rotating machine, and the other end is kept fixed, at 1000 rpm Rotate at a constant speed of 30 seconds at a speed of 1 minute to obtain secondary fibers with a length of about 10 cm and a diameter of about 150 µm.

Embodiment 3

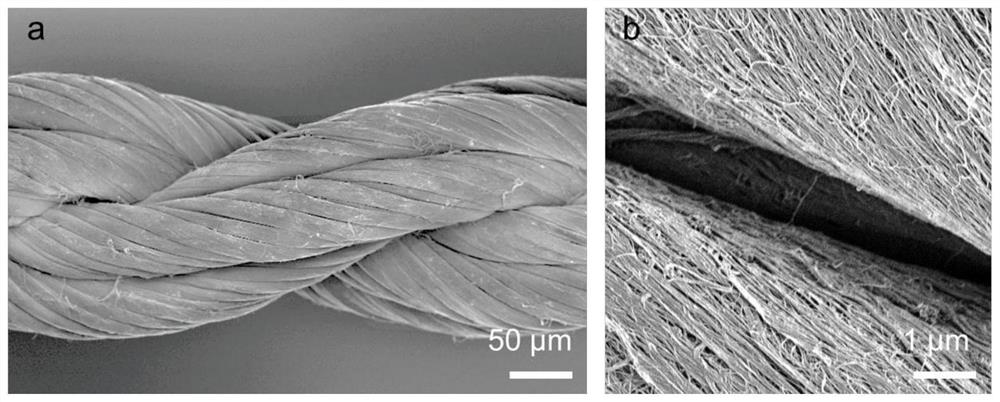

[0036] Embodiment 3, the preparation of tertiary double helical carbon nanotube fiber

[0037] Five secondary fibers with a length of 20 cm and a diameter of 150 µm are arranged in parallel, gathered together in one place, fixed at both ends, one end is fixed on the rotating machine, and the other end is kept fixed, and rotated at a constant speed of 1000 rpm For 30 seconds, remove both ends at the same time and keep the length unchanged, fix it on the paper, clamp the middle of the fiber with tweezers, fold the fiber, make the two fixed ends overlap, and fix them together, release the tweezers to release the stress, A tertiary double helix structure fiber can be obtained.

[0038] Tertiary fibers with a double helix structure such as image 3 Shown in electron microscope image. The nano-scale pore structure of the primary fiber is preserved in the tertiary fiber, and a large number of micron-scale pore structures between the primary fiber and the file fiber are introduced a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com