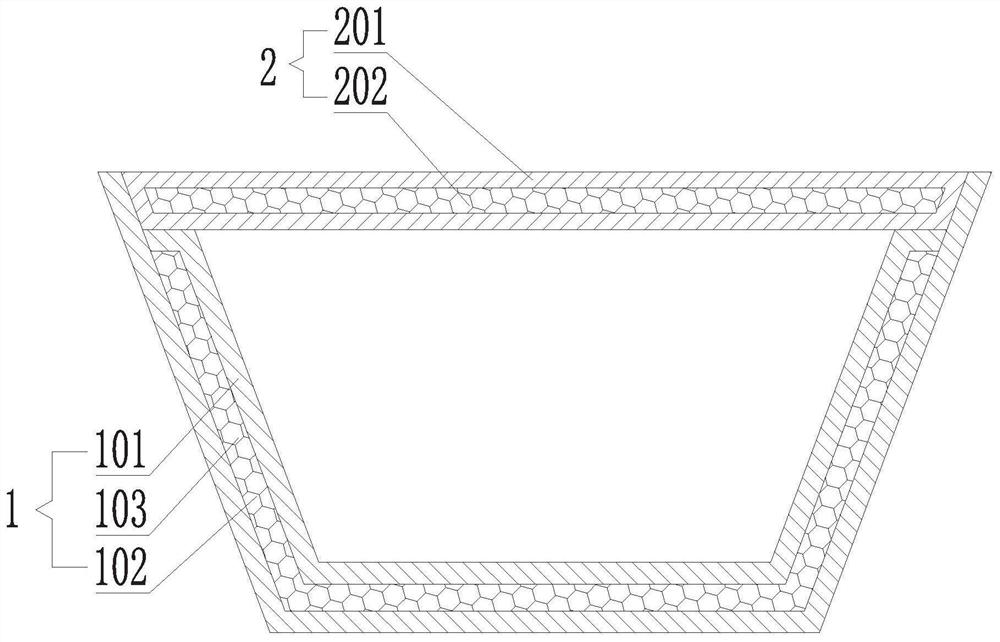

Method for preparing sandstone aggregate from manganese-silicon alloy hot-melt slag and application of sandstone aggregate

A technology of manganese-silicon alloy and hot slag, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of large water consumption, high pulverization rate, and increased taxation of industrial solid waste In order to achieve the effect of reducing the content of needle flakes, improving the uniformity of particles, and improving the comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0050] Prepare C30 concrete according to the specifications, the addition amount of each component and the experimental conditions are as follows:

[0051] C30 concrete ratio and slump and expansion:

[0052]

[0053] Changes in the strength of C30 concrete:

[0054] Age / d 3 7 28 Compressive strength / MPa 11.06 24.79 35.34

experiment example 2

[0056] Prepare C30 concrete according to the specifications, the addition amount of each component and the experimental conditions are as follows:

[0057] C40 Concrete Proportion, Slump and Expansion

[0058]

[0059]

[0060] Changes in the strength of C40 concrete:

[0061] Age / d 3 7 28 Compressive strength / MPa 14.67 33.12 46.85

experiment example 3

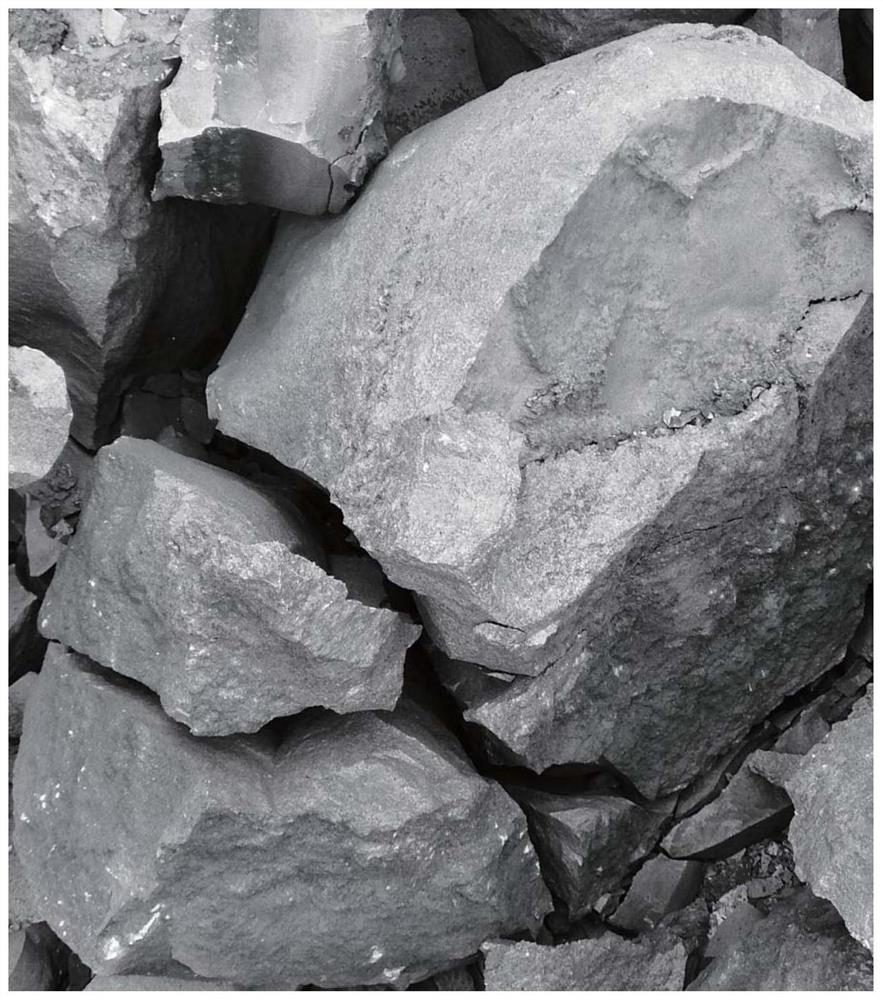

[0063] Manganese-silicon alloy hot slag aggregates are prepared according to the method provided by the invention, wherein the particle size of the coarse aggregate is 5-25mm, the particle size of the fine aggregate is 5-0.15mm, and the cementitious material adopts 42.5 ordinary Portland cement and 95-grade mineral powder, water-reducing agent is polycarboxylate dry powder, prepared high-performance concrete, and tested its slump, expansion and compressive strength changes; among them, cementitious material, coarse aggregate, fine The amount of aggregate and water added is the added mass (kg) corresponding to each cubic concrete, and the unit of slump and expansion is mm.

[0064] Proportion of high performance concrete and slump and expansion:

[0065]

[0066] High Performance Concrete Strength:

[0067] Age / d 3 7 28 Compressive strength / MPa 61.54 73.79 89.34

[0068] Through the above experimental example, it can be seen that the sandstone aggr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com