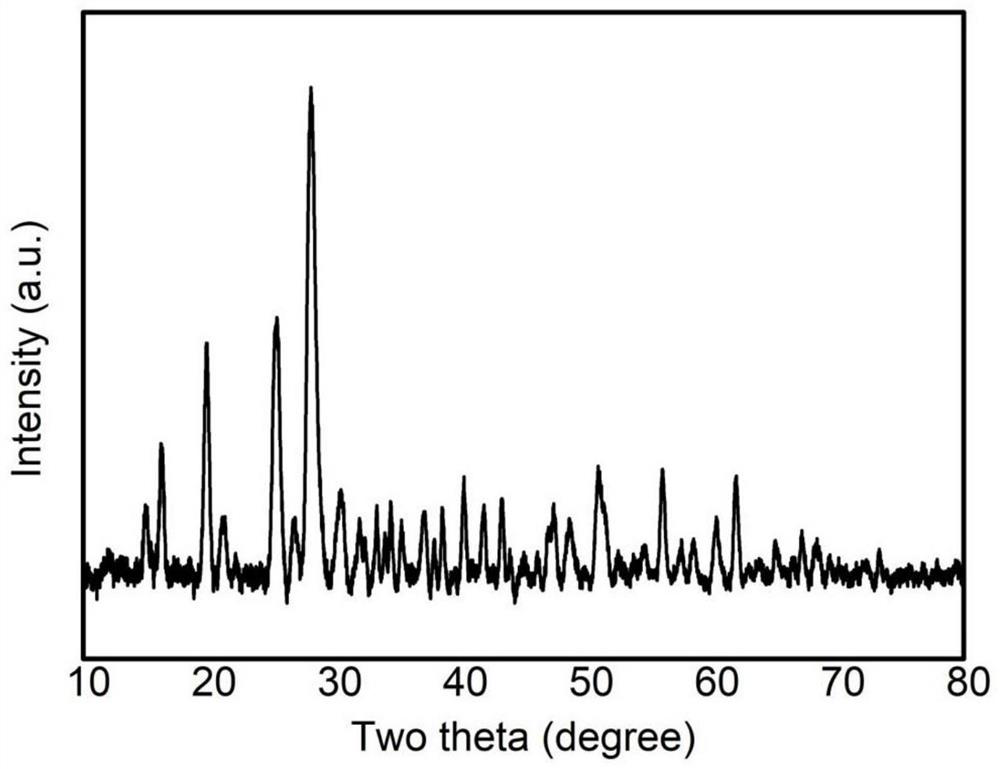

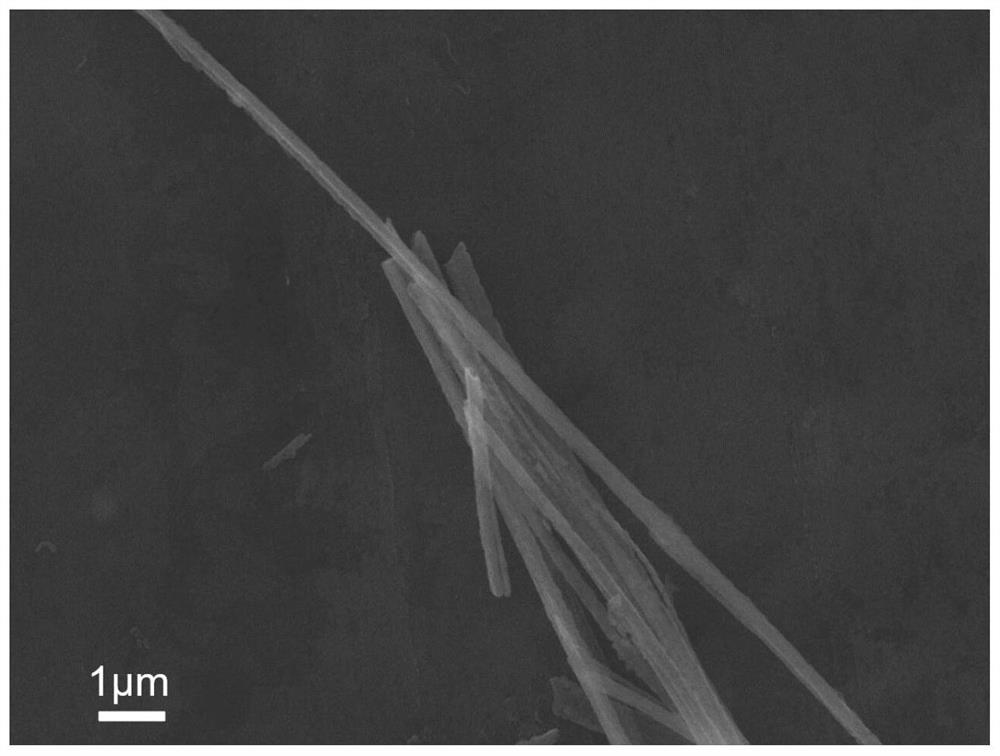

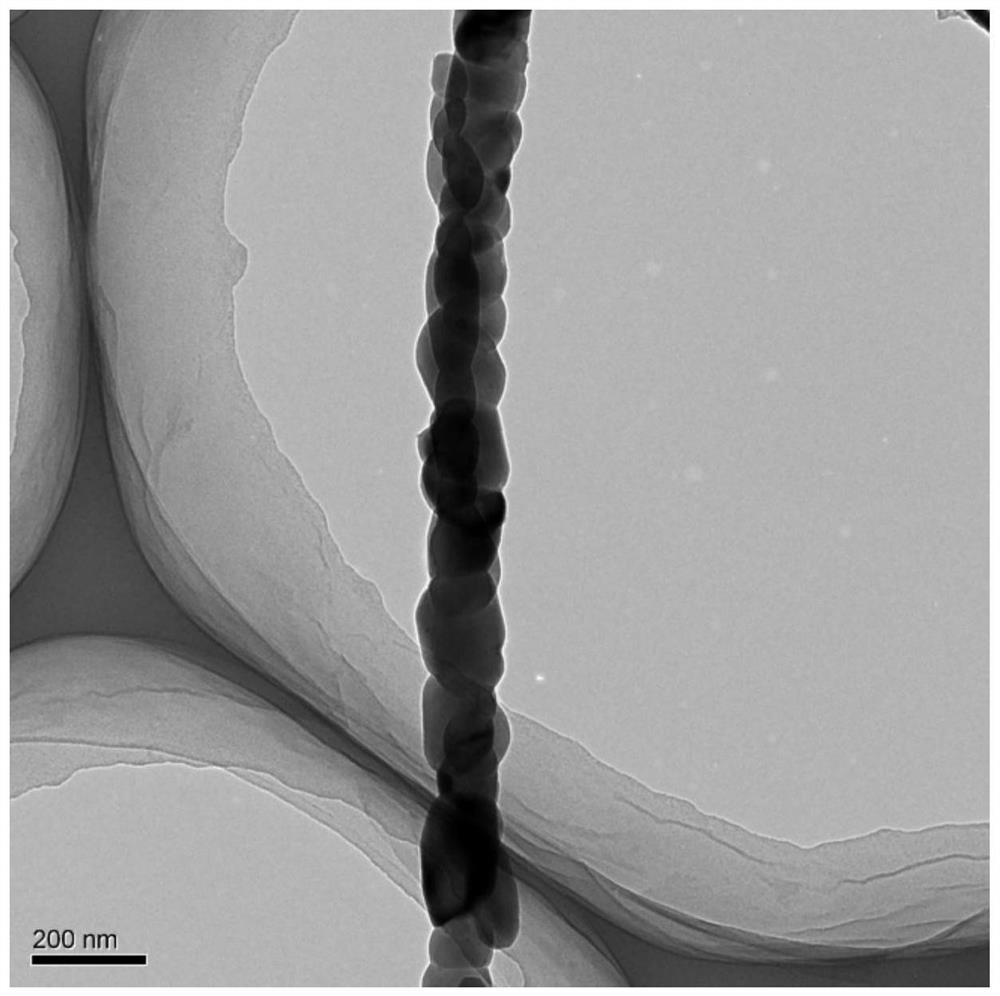

Zn2V2O6 nanowire, preparation method thereof and zinc ion battery positive electrode containing Zn2V2O6 nanowire

A zinc-ion battery and nanowire technology, which is applied in the field of nanomaterials and electrochemistry, can solve problems such as short cycle life, zinc dendrites, and self-discharge, and achieve good safety performance, uniform appearance, and long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 of the present invention provides a Zn 2 V 2 o 6 A method for preparing nanowires, comprising the steps of:

[0032] Step S1, measure 10-15mL of H with a mass fraction of 30% 2 o 2 In a 50mL beaker, weigh 1.3mmol (0.237g) V 2 o 5 Slowly add to the beaker, mix and stir for 3-4 hours; obtain the first mixed solution;

[0033] Step S2, weighing 0.04 g of PEG (polyethylene glycol, 4K), adding it to the first mixed solution in step S1, and stirring for 4-12 hours to obtain a second mixed solution;

[0034] Step S3, transfer the second mixed solution of step S2 into a 100mL beaker, add 50mL deionized water, stir for 1 hour to obtain the third mixed solution, transfer the third mixed solution to a 100mL reaction kettle, and put it in an oven at 180°C for The hydrothermal reaction was carried out for 48 hours. After the reaction was completed, it was taken out and cooled to room temperature to obtain the first solid product in the form of green floc;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com