Preparation process of modified super-capacitor carbon

A preparation process and capacitive carbon technology, which is applied in the preparation/purification of carbon, hybrid capacitor electrodes, inorganic chemistry, etc., can solve the problem of low capacitance, improve pseudocapacitive performance, increase capacitance, and improve cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

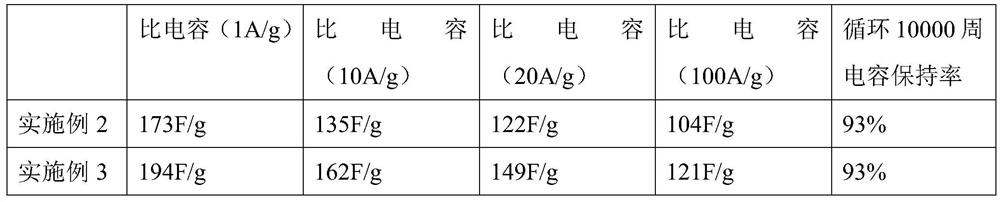

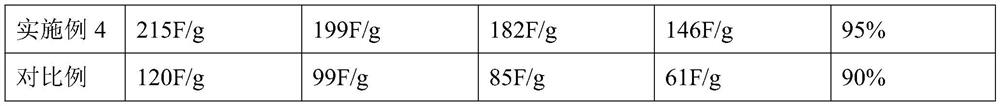

Examples

preparation example Construction

[0040] The preparation of porous carbon requires the carbon source to be obtained by high-temperature pore formation under the action of a pore-forming agent. The pore size is also difficult to distribute uniformly, and the pore-forming agent of the non-electrochemically active component is difficult to separate, which will greatly reduce the overall specific capacity; The self-assembled micelles of the permanent polystyrene-b-polyoxyethylene block polymer in a specific solvent were used as a template, and glucose was used as a carbon source to prepare polymer microspheres loaded with selenium on the surface. After calcination, the polymer microspheres Carbonization to obtain porous carbon with evenly loaded selenium on the surface, composite selenium-loaded porous carbon with phosphorus-doped activated carbon, and prepare a modified porous carbon material by high-temperature pyrolysis, based on the synergistic effect of selenium and phosphorus, improve the cycle of activated ca...

Embodiment 1

[0052] A preparation process of modified supercapacitor carbon, comprising the following steps:

[0053] S1. Carbon source solution preparation

[0054] Weigh 1 part of selenium powder, 8 parts of sodium borohydride, add 100 parts of deionized water, and 2 Stir continuously under the atmosphere until clarification, then add 5 parts of glucose, in N 2 Continue stirring under the atmosphere until clear to obtain solution A;

[0055] S2. Preparation of selenium-loaded porous carbon

[0056] Stir and dissolve the polystyrene-b-polyoxyethylene block polymer in tetrahydrofuran solvent at a material-to-liquid ratio of 10 g / L to obtain a polymer solution, add ethanol aqueous solution, and stir vigorously at a stirring rate of 800-1000 rpm for 10 minutes. To obtain solution B, the volume ratio of ethanol and water in the aqueous ethanol solution is 2:1, and the mixing volume ratio of the aqueous ethanol solution to the polymer solution is 3:1, and then quickly add the same volume of...

Embodiment 2

[0064] Mix the modified supercapacitor carbon and PTFE described in Example 1 evenly in a ratio of 10:1 by mass to obtain a paste, which is rolled into a sheet with a thickness of 200 μm, cut into an appropriate size, and applied with a pressure of 40 MPa Press the flakes onto a stainless steel grid to prepare a supercapacitor electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com