Lignin-based molded activated carbon and preparation method thereof

A shaped activated carbon and lignin-based technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., can solve the problems of unable to shape and prepare granular activated carbon, low energy consumption and production cost, and inability to industrialize production, etc., to achieve change Effects of glass transition temperature and softening point, improvement of performance, reduction of degree of polymerization and molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

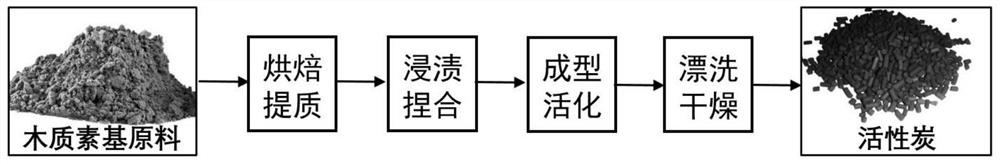

[0027] A method for preparing lignin-based shaped activated carbon by baking pretreatment, the process flow is as follows figure 1 shown. The method specifically includes the following steps:

[0028] (1) Sieve the residue (lignin content 40.3%, hemicellulose content 0.5%) after extracting xylose from corncobs, and take the part with a particle size larger than 40 mesh and bake at 250 ° C for 3 hours;

[0029] (2) Weigh the roasted corncob extract xylose residue and phosphoric acid with a mass fraction of 55% and mix them according to the impregnation ratio of 1:2, and impregnate and knead at a temperature of 140°C, and the impregnation and kneading is completed in the closed silo of the kneader , after the kneading is completed, put it into an oven at 140°C, and adjust the dry and wet state of the material until it can be formed and granulated;

[0030] (3) Transfer to the forming mold for granulation. After granulation, bake at 70°C until hardened, then heat up to 140°C an...

Embodiment 2

[0034] A method for preparing lignin-based shaped activated carbon, specifically comprising the following steps:

[0035] (1) Sieve the residue after extracting xylose from corncobs (with a lignin content of 40.3%, and a hemicellulose content of 1.5%), and take the part with a particle size greater than 40 mesh and bake it at 260°C for 3 hours;

[0036] (2) Mix the xylose residue extracted from the corncob after the baking treatment with phosphoric acid with a mass fraction of 55% according to the impregnation ratio of 1:1.5, and impregnate and knead at a temperature of 140° C., and the kneading is completed in a closed silo of the kneader, After the kneading is completed, put it into an oven at 140°C, and adjust the dry and wet state of the material until it can be formed and granulated;

[0037] (3) Transfer to a molding mold for granulation, bake at 70°C until hardened after granulation, then heat up to 140°C for drying, move to an activation furnace for activation at 600°C...

Embodiment 3

[0040] A method for preparing lignin-based shaped activated carbon, specifically comprising the following steps:

[0041] (1) Sieve the lignin raw material (with a lignin content of 79.4% and a hemicellulose content of 0.1%) extracted by alkali after extracting xylose from corn cobs, and bake the part with a particle size greater than 40 mesh at 260°C for 3 hours;

[0042] (2) Weigh the baked corncobs to extract xylose and then mix the lignin extracted by alkali with phosphoric acid with a mass fraction of 55% according to the impregnation ratio of 1:3, and impregnate and knead at a temperature of 140°C, and knead in a kneader Finished in a closed silo, put it into a 140°C oven after kneading, and adjust the dry and wet state of the material until it can be shaped and granulated;

[0043] (3) Transfer to a forming mold for granulation. After granulation, bake at 70°C until hardened, then heat up to 140°C and dry. After drying, move to an activation furnace and activate at 550°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com