Degradable Mg-Nd-Zn-Sc biomedical magnesium alloy and preparation method thereof

A biomedical, magnesium alloy technology, applied in medical science, tissue regeneration, prosthesis, etc., to achieve the effect of reducing galvanic corrosion, reducing corrosion rate, and increasing nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

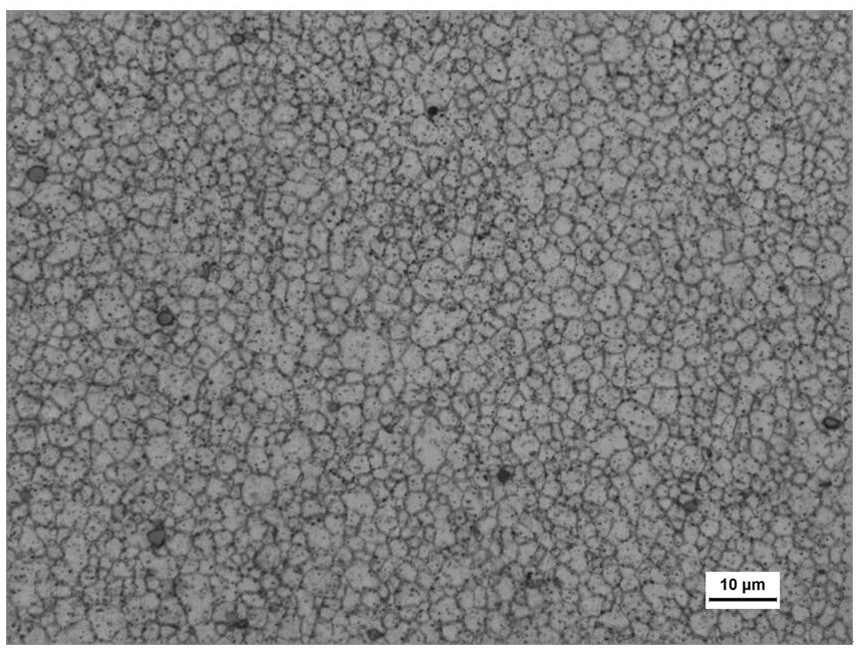

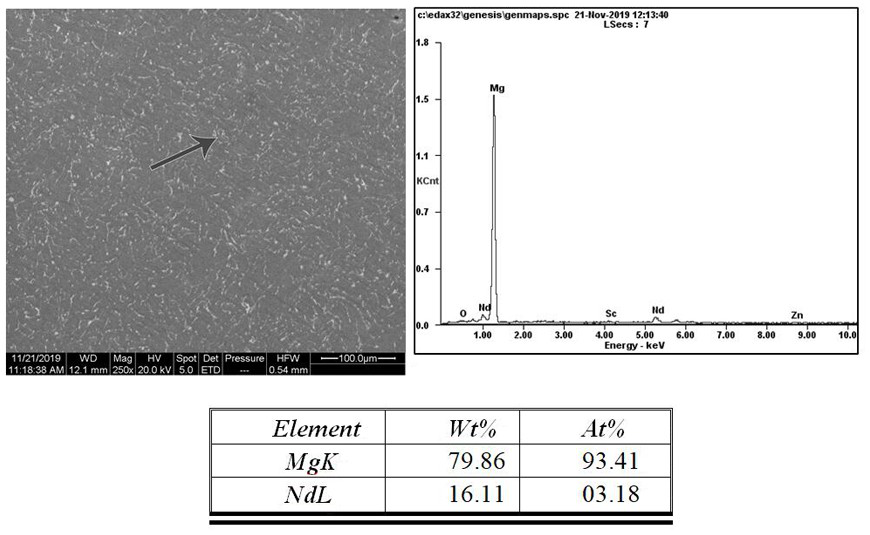

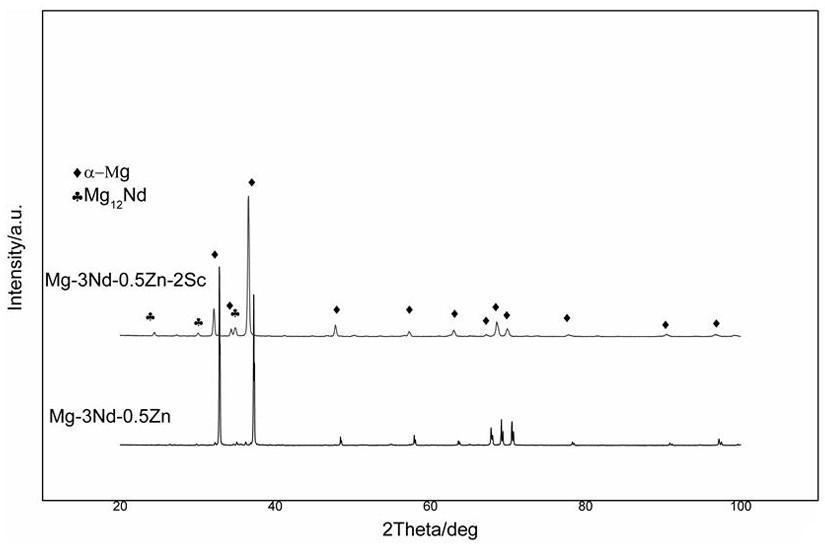

Image

Examples

preparation example Construction

[0054] Step 2 Preparation of Extruded Alloy Specimen

[0055] a. Cut the cast alloy blank into a cylinder with a wire cutting machine, and polish it with a grinder;

[0056] b. Put the cleaned blank into the holding furnace, and place it in the alumina powder at 350-450°C for homogenization annealing for 24 hours;

[0057] c. Polish the oxide layer of the annealed blank again;

[0058] d. Put the billet into the mold coated with lubricant, and adjust the temperature to 400°C for preheating;

[0059] e. After the temperature reaches 400°C, keep it warm for 20 minutes and carry out extrusion. The extrusion ratio is 11~30, and the extrusion speed is 1~4m / min. During the extrusion process, the temperatures of the extrusion cylinder, gasket, mold, and billet are respectively 250°C, 300°C, 350°C, 400°C;

[0060] f. After the extrusion is finished, water-cool the extruded bar.

Embodiment 1

[0062] The composition (mass percentage) of the alloy is: 1.0%Nd, 0.5%Zn, 2.0%Sc, and the remaining elements are Mg. The preparation process of the alloy is as follows: put the steel crucible into a resistance furnace to preheat to 400°C for 10 minutes, and then pass in a mixed gas of carbon dioxide and sulfur hexafluoride, wherein the volume ratio of carbon dioxide and sulfur hexafluoride is 97:3 , add 486.20g of high-purity magnesium ingot, cover the furnace cover, and raise the temperature to 720°C; after the furnace charge is completely melted, add 40.33g of dried Mg-30Sc master alloy to the crucible; after 10min, raise the temperature to 800°C, start Timing heat preservation, the heat preservation time is 90min. After the heat preservation is over, add 20.17g of dried Mg-30Nd master alloy, and lower the temperature to 720°C at the same time. After 15 minutes, add 3.3g of dried high-purity zinc ingot, and wait until the melt is completely melted and heat for 10 minutes. , ...

Embodiment 2

[0064] The composition (mass percentage) of gold is: 3.0%Nd, 0.5%Zn, 4.0%Sc, and the remaining elements are Mg. The preparation process of the alloy is as follows: put the steel crucible into a resistance furnace to preheat to 400°C for 10 minutes, and then pass in a mixed gas of carbon dioxide and sulfur hexafluoride, wherein the volume ratio of carbon dioxide and sulfur hexafluoride is 97:3 , add 405.53g of high-purity magnesium ingot, cover the furnace cover, and raise the temperature to 720°C; after the furnace charge is completely melted, add 80.67g of dried Mg-30Sc master alloy into the crucible; after 10min, raise the temperature to 800°C, start Timing heat preservation, the heat preservation time is 90min, after the heat preservation is over, add 60.50g of dried Mg-30Nd master alloy, and lower the temperature to 720°C at the same time, add 3.3g of dried high-purity zinc ingot after 15min, wait until the melt is completely melted and heat for 10min , poured into a metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com