Modified heavy calcium carbonate as well as preparation method and application thereof

A heavy calcium carbonate, modified technology, applied in the field of materials, can solve the problems of unfriendly environment, difficult to guarantee, no ability to adsorb formaldehyde, etc., and achieve the effect of improving adsorption effect, good dispersibility, and good lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

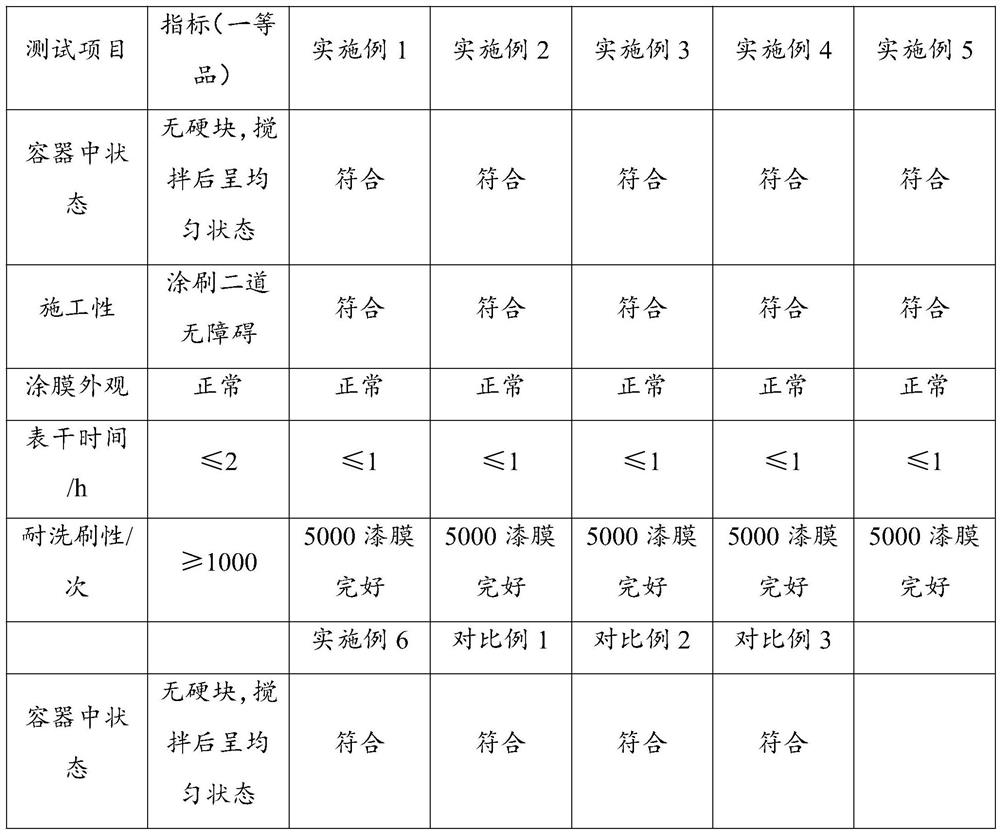

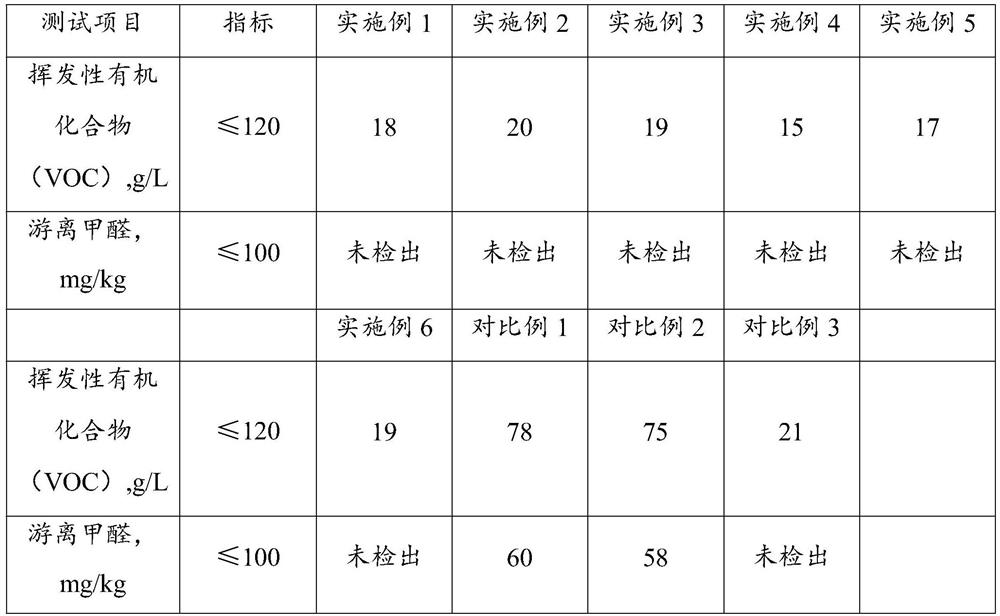

Examples

preparation example Construction

[0013] The embodiment of the present invention provides a kind of preparation method of modified ground calcium carbonate, comprises the steps:

[0014] Step 101, put the cleaned and dried shells into a muffle furnace, calcinate them at 550°C-650°C for 5-6 hours, take them out and cool them down to room temperature, and then use secondary wet grinding to obtain shell powder.

[0015] In the embodiment of the present invention, shell is a kind of natural raw material, is made of CaCO such as calcite or aragonite 3 It is composed of minerals (inorganic phase) and organic matter (organic phase), and its main components are calcium carbonate, calcium oxide, calcium hydroxide and other calcified substances.

[0016] Before putting the shells into the muffle furnace for calcination, soak the shells with a citric acid solution with a concentration of 0.1% to 0.2% for 1 to 2 hours to remove organic and / or inorganic impurities adhering to the surface of the shells, and then use the Af...

Embodiment 1

[0029] The preparation steps of the modified heavy calcium carbonate of the present embodiment are as follows:

[0030] Put the cleaned and dried shells into a muffle furnace, calcinate them at 550°C for 5 hours, take them out and cool them to room temperature, and grind the calcined shells cooled to room temperature for 50 minutes at a grinding temperature of 20°C; Grade shell powder; the above-mentioned primary grinding powder is ground at a grinding temperature of 32°C for 20 minutes to obtain secondary shell powder; the above-mentioned secondary shell powder, vegetable glycerin, polymaleic acid and ammonium nitrate are mixed according to a mass ratio of 18:1 :6:0.2 for mixing and soaking for 0.5h to obtain shell slurry; the above shell slurry was spray-dried, and during the spraying process, the above shell slurry was sprayed with a titanate coupling agent and a mass concentration of 10% The mixture of calcium hydroxide solution, the angle of 60 ° between the jet flow of t...

Embodiment 2

[0032] The preparation steps of the modified heavy calcium carbonate of the present embodiment are as follows:

[0033]Put the cleaned and dried shells into a muffle furnace, calcinate them at 600°C for 5 hours, take them out and cool them to room temperature, and grind the calcined shells cooled to room temperature for 40 minutes at a grinding temperature of 25°C; Grade shell powder; the above-mentioned primary grinding powder is ground at a grinding temperature of 35°C for 30 minutes to obtain secondary shell powder; the above-mentioned secondary shell powder, vegetable glycerin, sodium polyacrylate and urea are mixed according to the mass ratio of 18:2:5 : 0.3 mixed, and soaked for 1h, to obtain shell slurry; above-mentioned shell slurry is spray-dried, and in the spraying process, spraying titanate coupling agent and mass concentration to the above-mentioned shell slurry is calcium hydroxide of 15% The mixture of the solution, the angle between the jet flow of the shell sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com