Gallium oxide film and heteroepitaxial growth method and application thereof

A technology of heteroepitaxy and growth methods, applied in the field of semiconductor epitaxy, can solve the problems of lack of symmetry, small size, heteroepitaxial lattice mismatch, etc., to solve the problem of small nucleation size, avoid dislocations and cracks, reduce The effect of lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 gallium oxide heteroepitaxy (random growth) on sapphire substrate

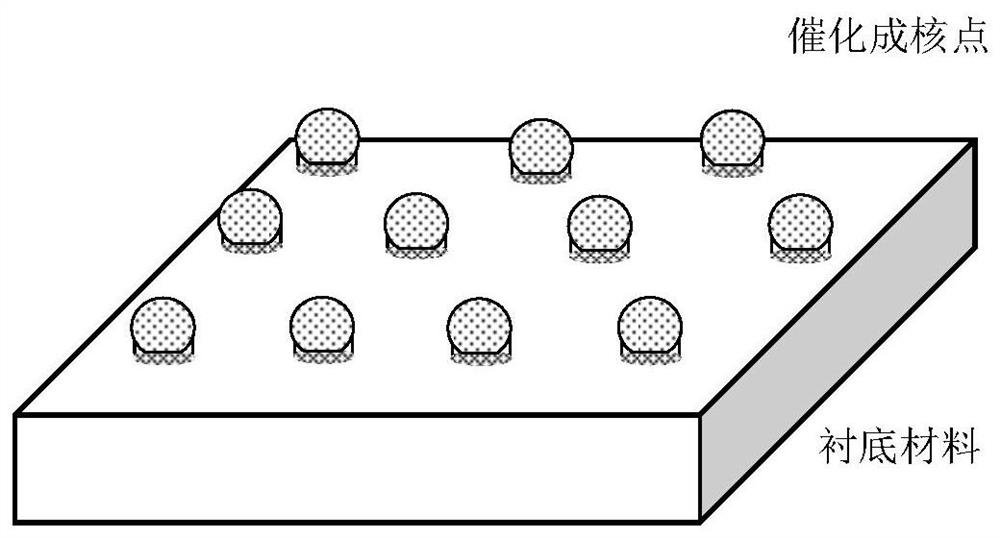

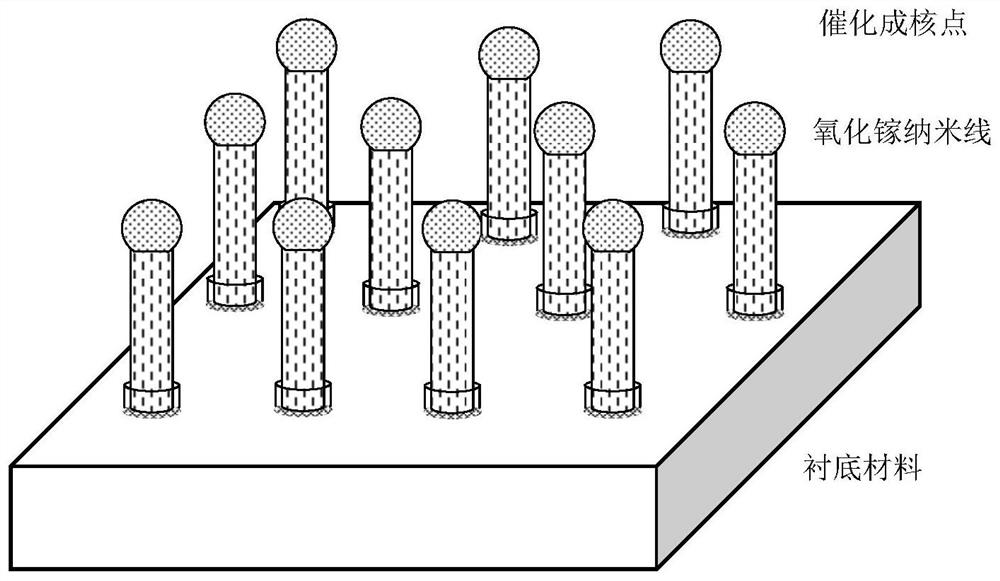

[0067] (1) if figure 1 As shown, at 300-1000 °C, the nano-metal catalytic particles dispersed on the substrate dissolve with the gaseous source of the growth material to form eutectic alloy droplets; then the alloy droplets dissolve the component atoms of the growth material, and when the alloy droplets After the component atoms in the supersaturation, crystallization begins at the boundary between the droplet and the substrate, and promotes the movement of the catalytic droplet, thereby growing one-dimensional nanowire materials (such as figure 2 shown).

[0068] (2) During the growth of nanowires, nanoscale low-melting catalytic droplets are formed. These catalytic droplets are generally eutectic alloys formed by metal particles and reactant materials. Commonly used metal catalysts include Au, Ag, Ni, Pt, etc. . If the element of the catalytic droplet is a certain element of the growt...

Embodiment 2

[0070] Example 2 Gallium oxide heteroepitaxy (patterned growth) on sapphire substrate

[0071] (1) Preparation of deposition dielectric mask layer and catalyst positioning

[0072] Deposit a layer of silicon oxide dielectric (gallium nitride, aluminum oxide, etc.) mask with a film thickness of 1-1000nm, and use photolithography, etching, or focused ion beam to open holes in the dielectric mask; or use an already patterned A thin substrate material is used as a growth template for gallium oxide nanowires, such as a porous anodic aluminum oxide film (AAO, Anodic Aluminum Oxide Template).

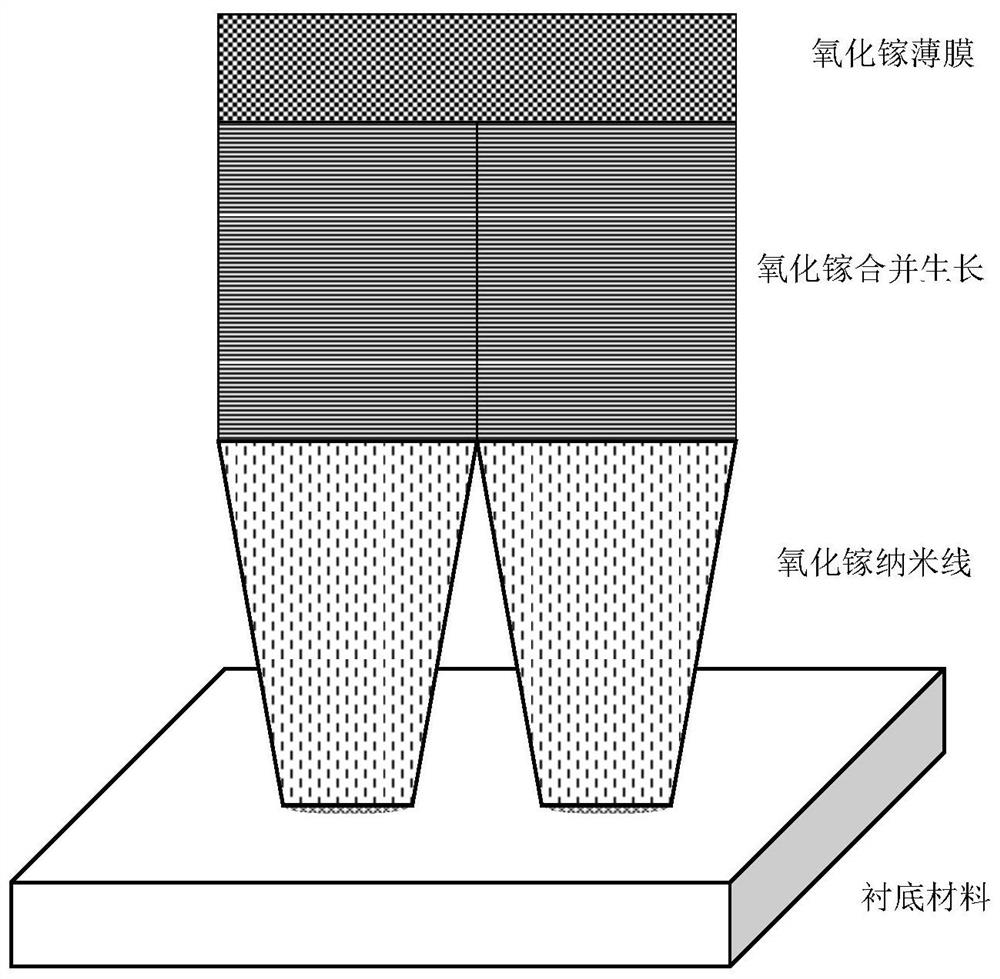

[0073] (2) Gallium oxide nanowire epitaxy

[0074] Send the patterned substrate material into the MOCVD reaction chamber for the growth of gallium oxide nanowires, and deposit Ga droplets as catalysts; use the catalytic effect of Ga droplets to epitaxy Ga 2 o 3 array of nanowires. Growth equipment is not limited to material growth equipment such as MOCVD, LPCVD, and PVD.

[0075] (3) Merg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com