Nano polymer ring, nano carbon ring and preparation method of nano polymer ring and nano carbon ring

A nano-polymer and nano-carbon ring technology, applied in the direction of nano-carbon, nanotechnology, etc., can solve the problems that cannot be converted into ring-shaped porous carbon materials, it is difficult to obtain a ring structure, and the size distribution is wide, so as to achieve a good ring shape The effect of simple shape and process and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

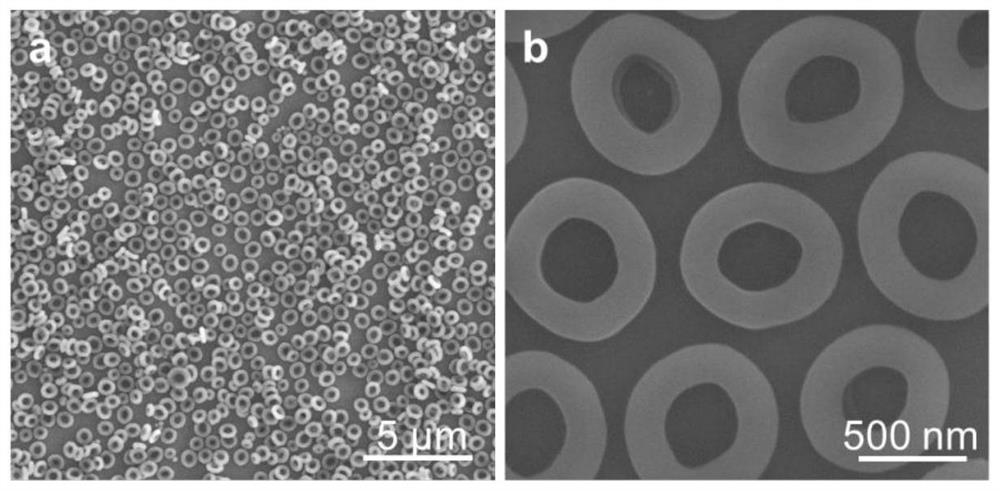

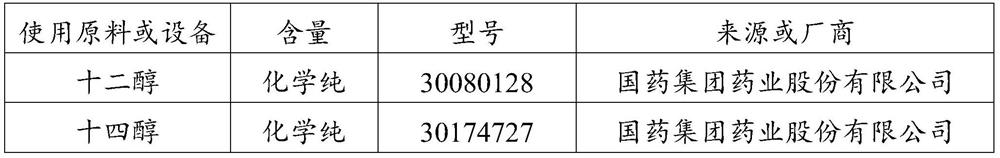

[0034] Weigh 400 mg of surfactant F127, add 40 mL of deionized water and stir to dissolve for 1 h. The F127 aqueous solution was heated up to 90°C, then 150 mg of dodecanol was added, and a translucent white emulsion was obtained after rapid stirring for 2 hours. The obtained white emulsion was placed at 20° C. for 120 h to obtain a white colloidal solution. Then another 440mg of resorcinol was weighed and placed in a 500mL round bottom flask, 360mL of deionized water was added, after the resorcinol was fully dissolved, 584 μL of formaldehyde solution (37wt%) was added successively, the above white colloidal solution, 60mg of n-propylamine , after stirring and reacting for 1 h, a white colloidal solution was obtained, and the obtained white colloidal solution was heated to 70° C. and stirred for 6 h. After the reaction is completed, the reactant is centrifuged at 8000 r / min for 5 min, washed with deionized water, and the product is dried to obtain monodisperse nanopolymer rin...

Embodiment 2

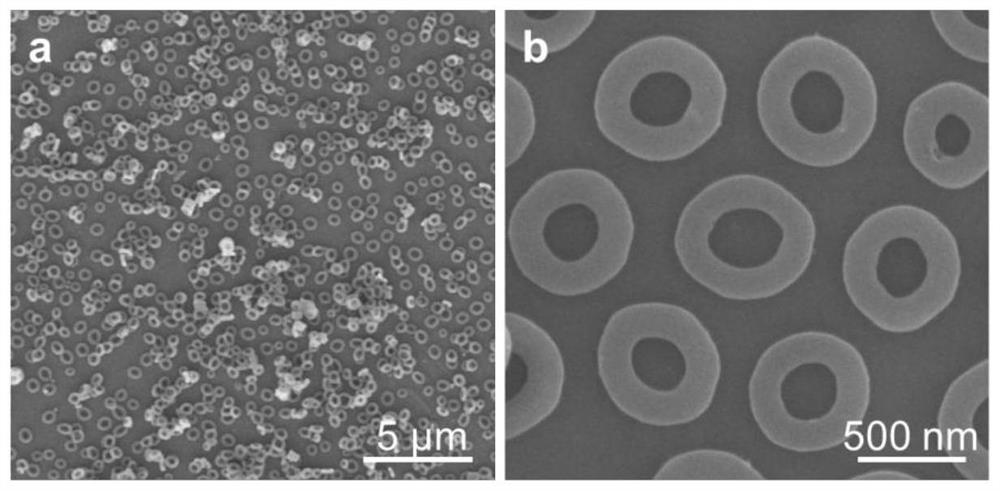

[0036] Place the nanopolymer ring prepared in Example 1 into a carbonization furnace for carbonization, protect it with argon from room temperature to 400°C at a rate of 3°C / min, and keep the temperature constant for 120 minutes; then raise the temperature from 400°C to The final carbonization temperature is 600°C, and the temperature is kept constant for 120 minutes. The obtained nano-carbon rings with shape retention have a BET specific surface area of 802 cm 3 / g, total pore volume 0.28cm 3 / g, the pore size is concentrated at 0.5nm. The nano-carbon obtained in this example has a diameter of 592±67nm and a cross-sectional circle diameter of 108±10nm.

Embodiment 3

[0038]Weigh 200mg of surfactant F127, add 20mL of deionized water, stir and dissolve at 20°C for 1h. The F127 aqueous solution was heated up to 80°C, then 100 mg of myristyl alcohol was added, and a translucent white emulsion was obtained after rapid stirring for 3 hours. The obtained white emulsion was placed at 30° C. for 96 h to obtain a white colloidal solution. Another 440mg of resorcinol was weighed and placed in a 500mL round bottom flask, and 380mL of deionized water was added. After the resorcinol was fully dissolved, 584 μL of formaldehyde solution (37wt%), the above-mentioned white colloidal solution, 60mg of n-propylamine, After stirring and reacting for 0.5 h, a white colloidal solution was obtained, which was heated to 90° C. and stirred for 4 h. After the reaction is completed, the reactant is centrifuged at 8000 r / min for 5 min, washed with deionized water, and the product is dried to obtain monodisperse nanopolymer rings. Protected by argon, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total pore volume | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com