Sodium ion battery positive electrode material, preparation method thereof and sodium ion battery

A technology for sodium ion batteries and cathode materials, which is applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor electrochemical cycle performance, slow reaction kinetics, affecting material properties, etc., and achieve suitable large-scale production. Application, the effect of improving specific surface area and tap density, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

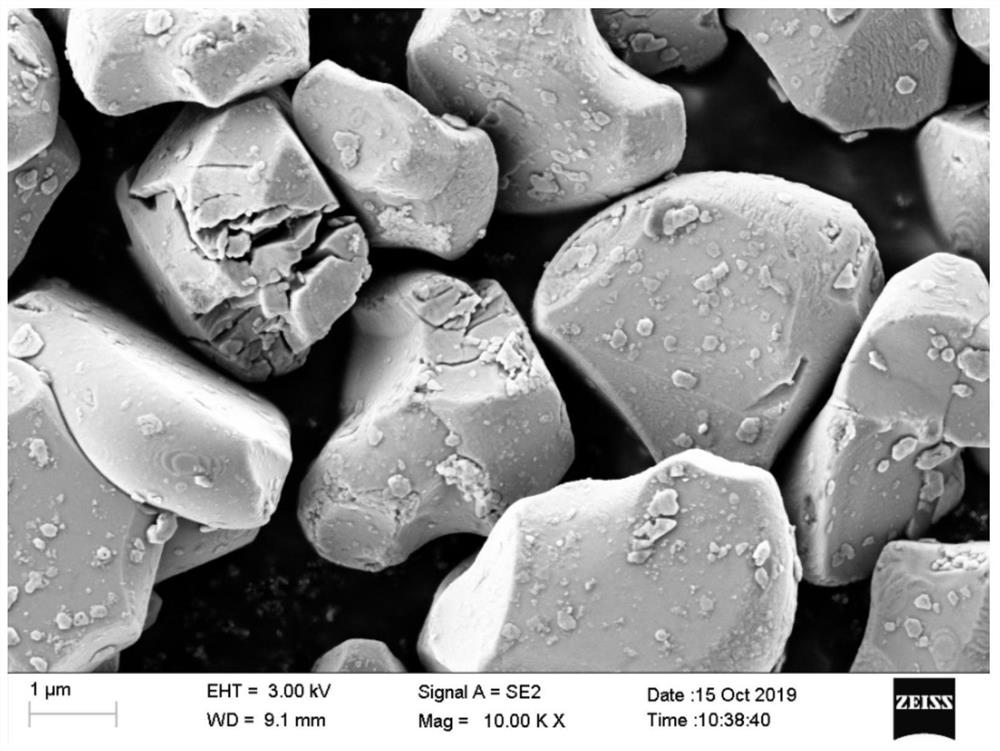

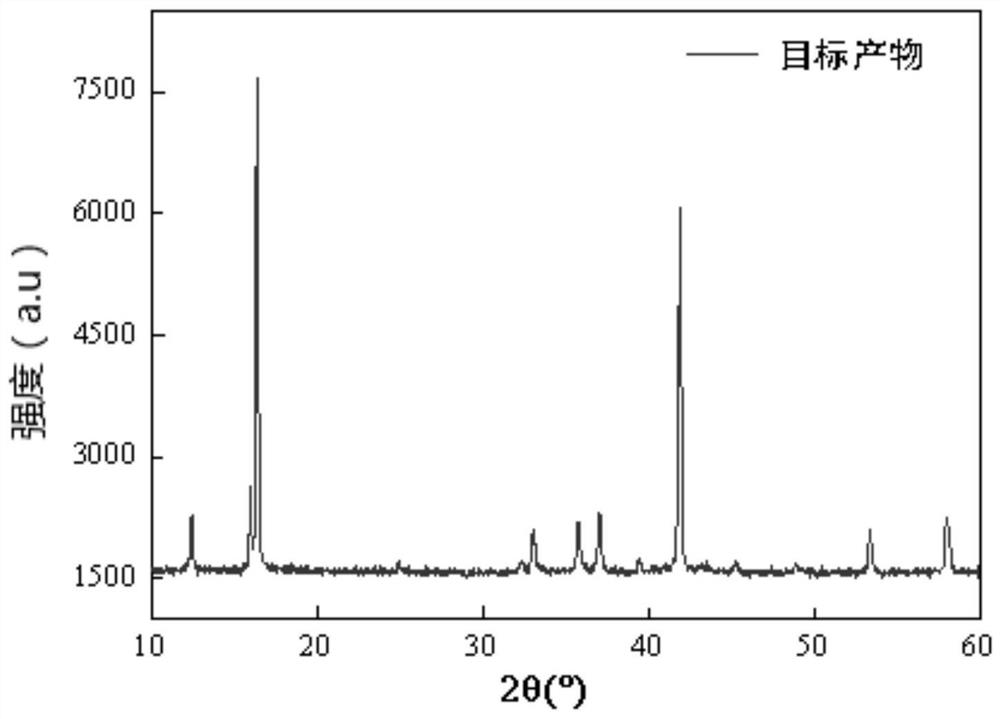

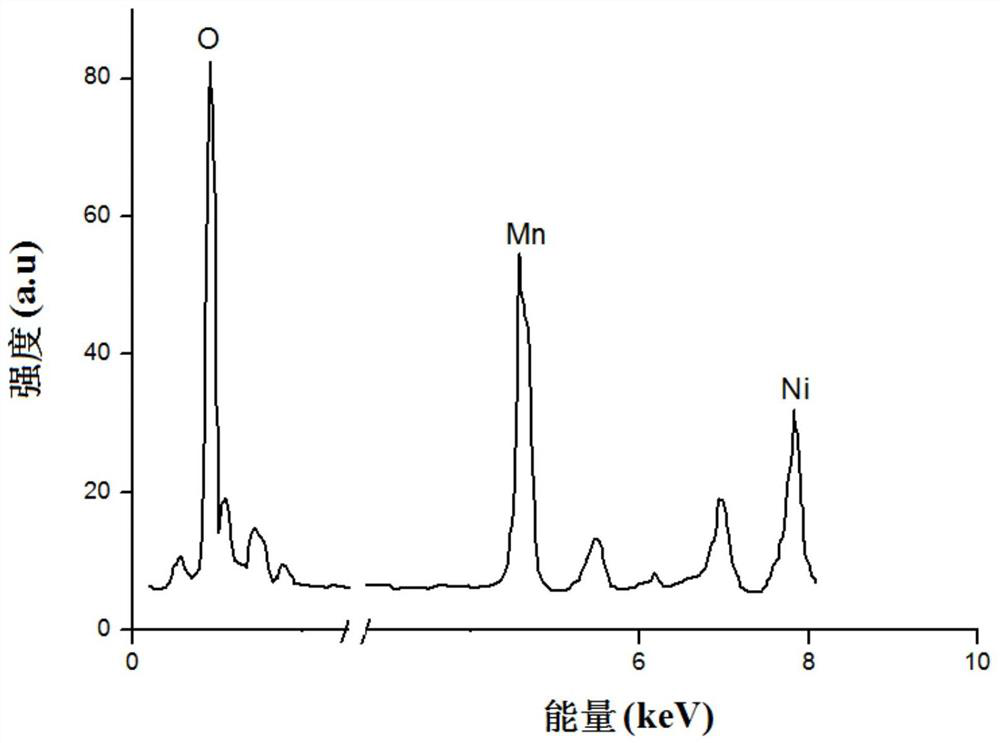

[0050] The present invention adopts following method to prepare sodium ion battery cathode material:

[0051](1) 55g CH 3 COONa, 82.1g (CH 3 COO) 2 Ni·4H 2 O and 164.2g (CH 3 COO) 2 Mn 4H 2 O (the molar ratio of Na, Ni, Mn is 0.67:0.33:0.67) is added in 1L ethanol respectively, obtains sodium acetate solution, nickel acetate solution and manganese acetate solution; Then sodium acetate solution, nickel acetate solution and manganese acetate solution Mix well and place in the autoclave, and seal the autoclave;

[0052] (2) Control the pressure of the autoclave to be 15MPa, and react the autoclave in an oil bath at 160° C. for 10 h;

[0053] (3) The product is washed with water and ethanol three times respectively, and dried at a temperature of 80° C. in a spray dryer for 10 minutes; stability in

[0054] (4) Put the sagger containing the cleaned product in a muffle furnace, the calcination temperature is 700°C, and the heating rate is 3.5°C / min, and it is calcined at a ...

Embodiment 2

[0058] The present invention adopts following method to prepare sodium ion battery cathode material:

[0059] (1) 72.25g NaNO 3 , 105.2g NiSO 4 ·6H 2 O and 174.6g Co(NO 3 ) 2 (the molar ratio of Na, Ni, Co is 0.85:0.4:0.6) join in 1L ethanol respectively, obtain sodium nitrate solution, nickel sulfate solution and cobalt nitrate solution; Then mix sodium nitrate solution, nickel sulfate solution and cobalt nitrate solution Place evenly in the autoclave, and seal the autoclave;

[0060] (2) Control the pressure of the autoclave to be 20MPa, and react the autoclave in an oil bath at 170° C. for 12 hours;

[0061] (3) The resultant was washed twice with water and twice with ethanol, and dried for 5 minutes at a temperature of 100° C. in a spray dryer;

[0062] (4) Put the sagger containing the cleaned product in a muffle furnace, the calcination temperature is 600°C, the heating rate is 2°C / min, and it is calcined at a high temperature for 10 hours in a compressed air atmos...

Embodiment 3

[0065] The present invention adopts following method to prepare sodium ion battery cathode material:

[0066] (1) 68g NaNO 3 , 54.8g Ni(NO 3 ) 2 with 88.1g MnCl 2 (the molar ratio of Na, Ni, Mn is 0.8:0.3:0.7) join in 1L ethanol respectively, obtain sodium nitrate solution, nickel nitrate solution and manganese chloride solution; Then sodium nitrate solution, nickel nitrate solution and manganese chloride solution The solution is mixed and placed in the autoclave, and the autoclave is sealed;

[0067] (2) Control the pressure of the autoclave to be 10MPa, and react the autoclave in an oil bath at 180° C. for 8 hours;

[0068] (3) The resultant was washed with water and ethanol three times respectively, and dried in a spray dryer at a temperature of 90° C. for 8 minutes;

[0069] (4) Put the sagger containing the cleaned product in a muffle furnace, the calcination temperature is 800°C, and the heating rate is 3°C / min, and it is calcined at a high temperature for 6 hours i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com